Implementing method for laser high-speed multiway carving

An implementation method, high-speed technology, applied in printing, plate preparation, etc., to achieve the effect of improving efficiency and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation is as follows:

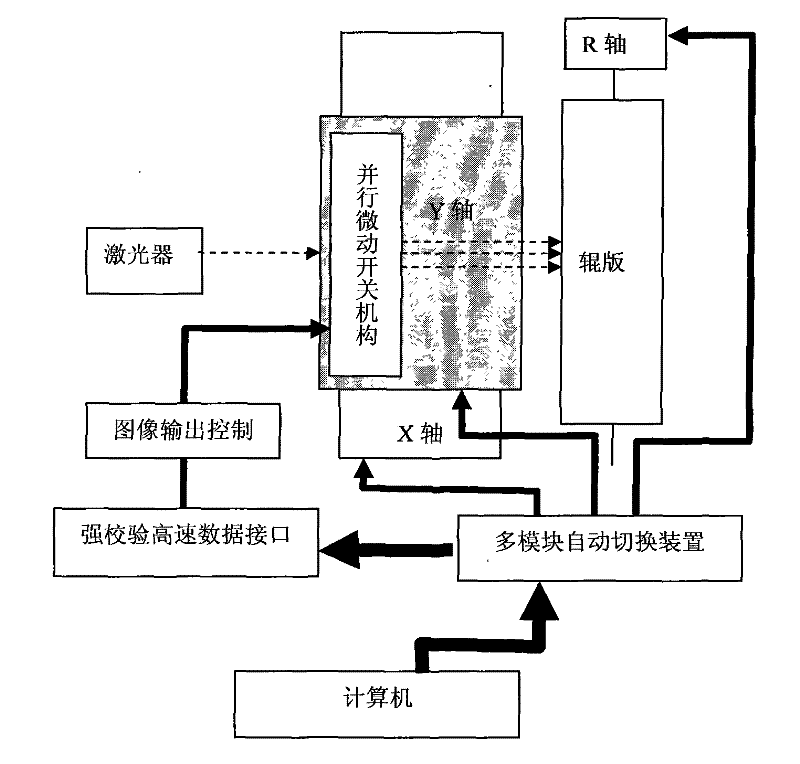

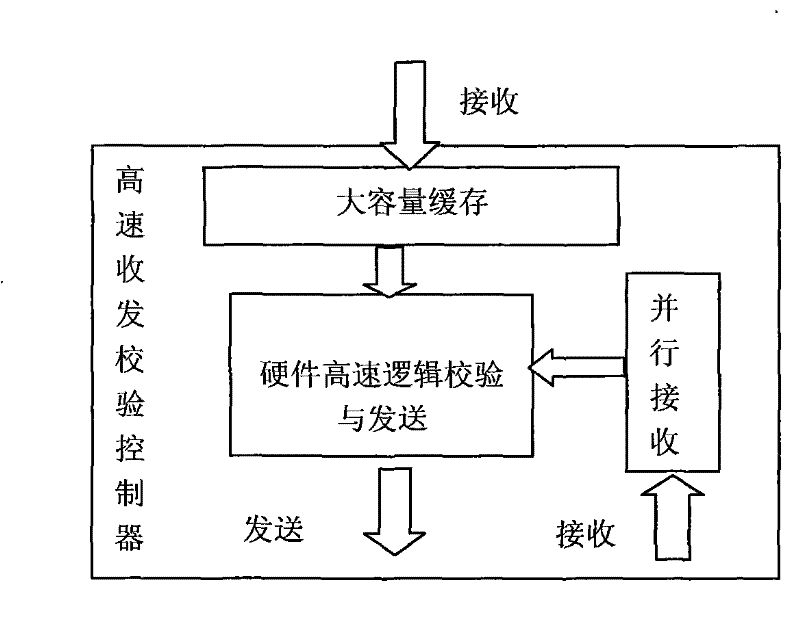

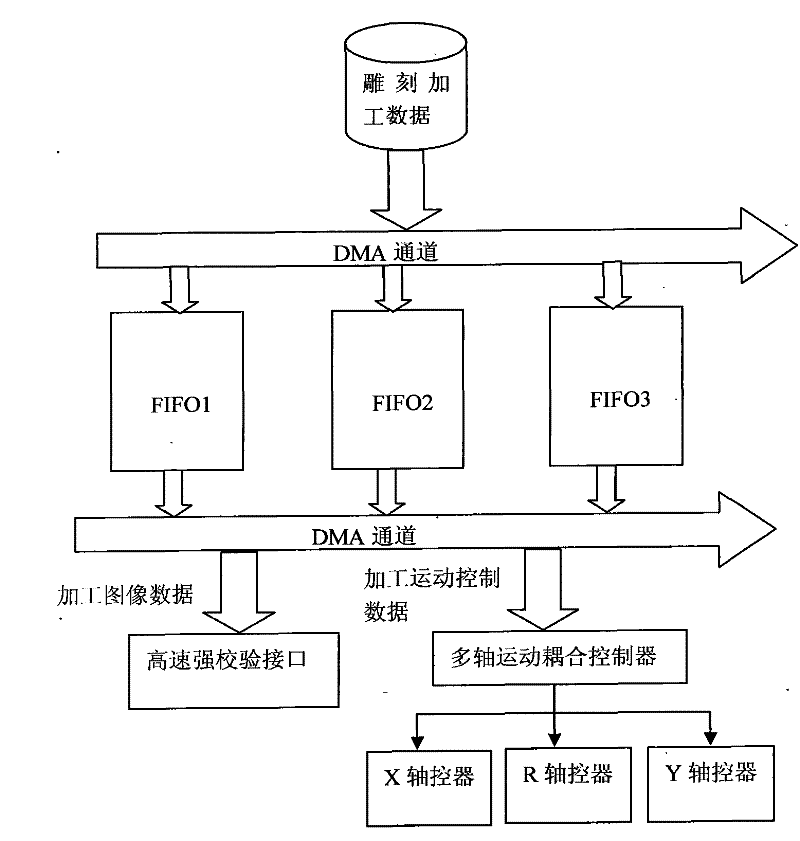

[0013] The roller plate is coated with photosensitive material, and the roller plate rotates according to a certain speed requirement. A beam of laser light emitted by the laser is transformed into multiple (more than 2) controllable lasers through a parallel micro-motion optical switch unit. The computer will The graphics to be engraved are digitized and sent to the high-speed interface with strong calibration. The parallel high-speed interface with strong calibration controls the parallel micro-motion optical switch unit, and changes the switching status of each laser according to the correlation of the graphics to be engraved. The high photosensitive material at different positions on the roller plate is ablated. Through a multi-module automatic switching device, the computer controls the rotation speed (R axis) of the roll plate, the movement of the laser along the radial direction (Y axis) and the axial movement (X axis)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com