Shading element, manufacturing method thereof and lens module

A manufacturing method and component technology, applied to optical components, optics, optical filters, etc., can solve problems such as large environmental impact and inability to meet the precision requirements of micro-optical components, and achieve low cost, prevent external electromagnetic interference, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

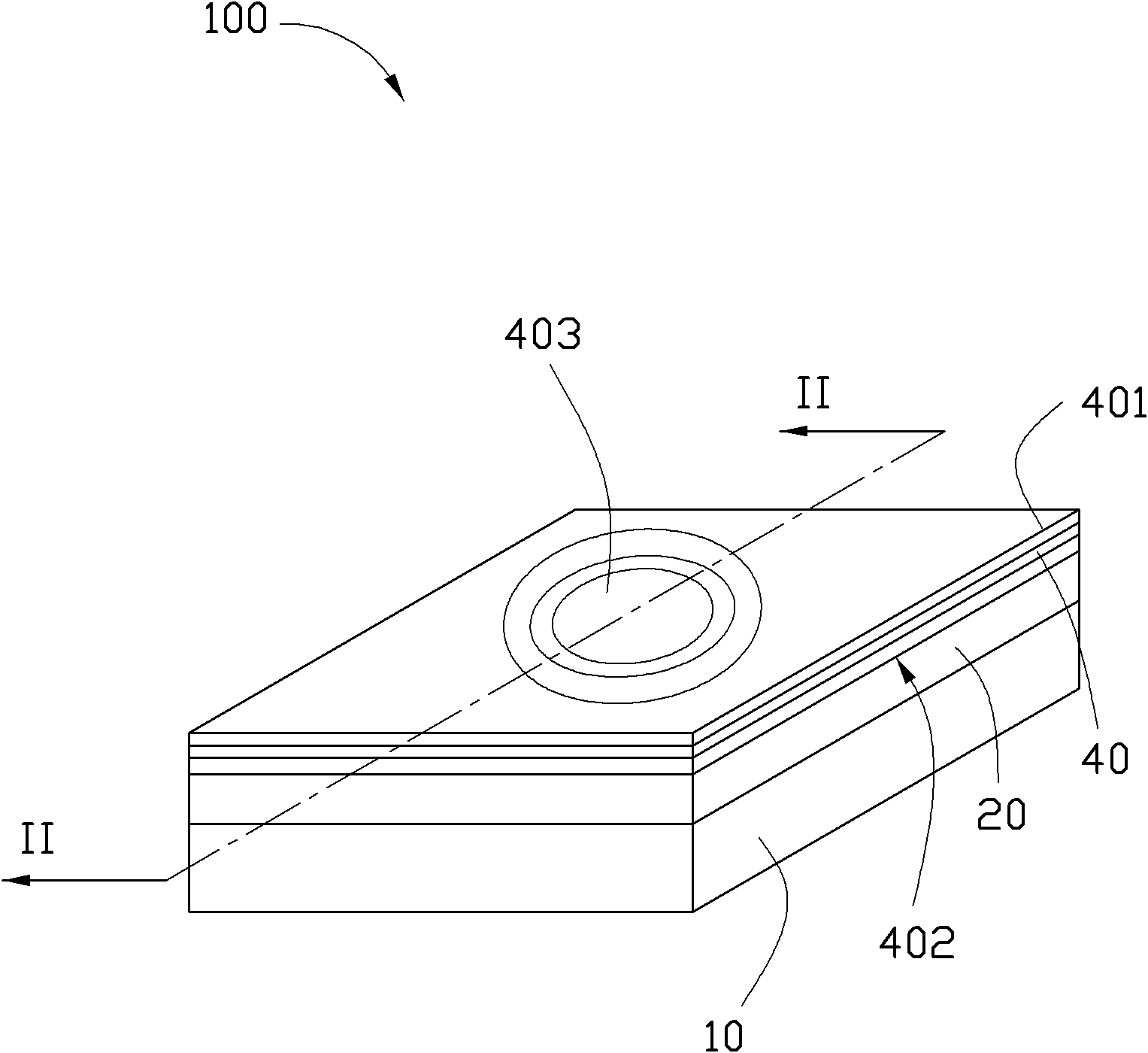

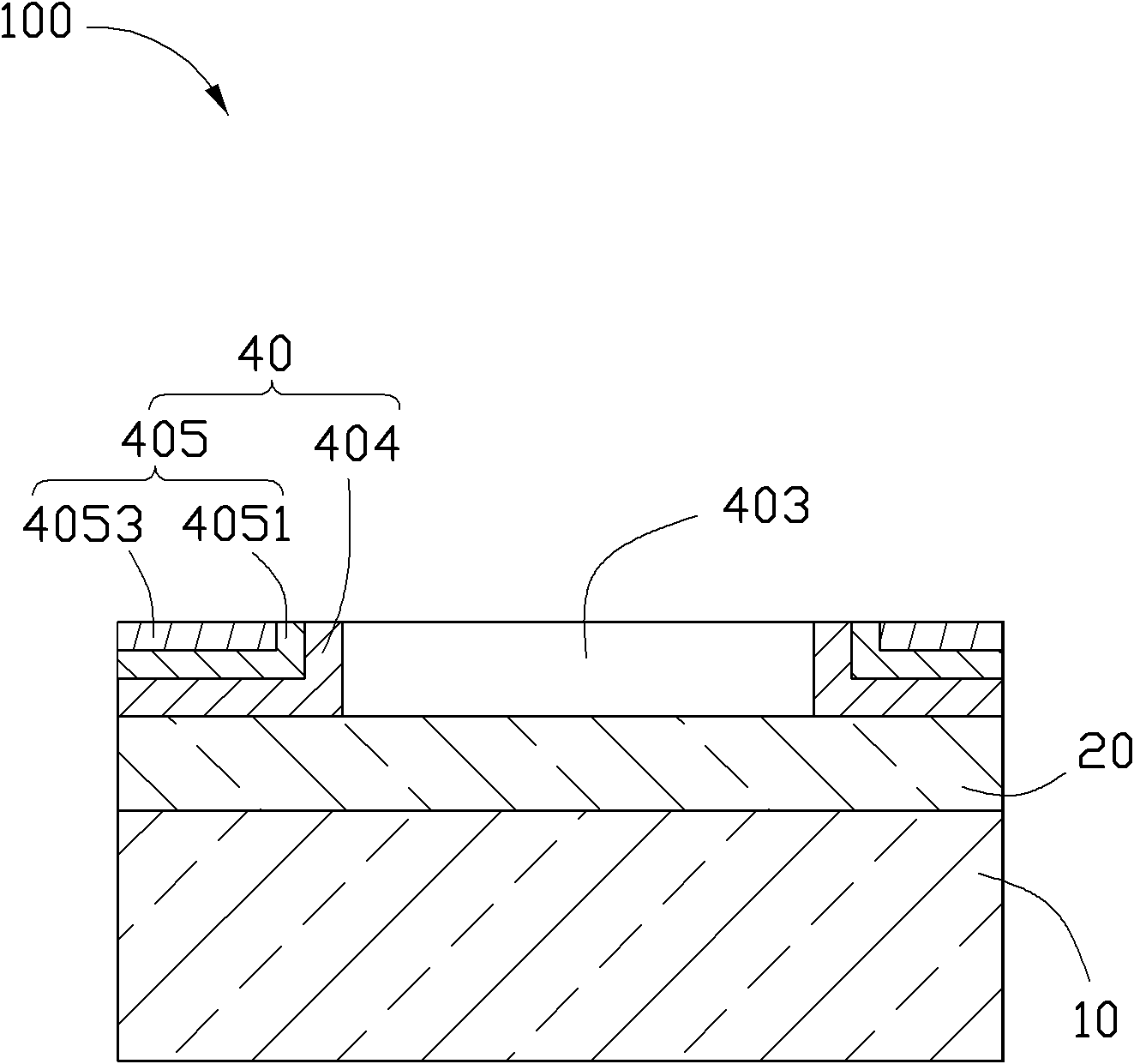

[0058] see figure 1 and figure 2 The light-shielding element 100 provided in the first embodiment of the present invention includes a light-transmitting flat plate 10 , a light-filtering layer 20 and a light-shielding shielding layer 40 arranged sequentially outward from the light-transmitting flat plate 10 .

[0059] The light shielding layer 40 has a top surface 401 away from the light-transmitting plate 10 , a bottom surface 402 close to the light-transmitting plate 10 , and a light-through hole 403 passing through the top surface 401 and the bottom surface 402 . The light shielding layer 40 includes a light shielding layer 404 formed on the filter layer 20 and a magnetic shielding layer 405 formed on the light shielding layer 404 . The part of the light shielding layer 40 away from the light through hole 403 is a magnetic shielding layer 405 and a light shielding layer 404 in sequence from the top surface 401 to the bottom surface 402 . The part of the light-shielding shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com