Method for regenerating and recycling wool dyeing wastewater

A technology for dyeing wastewater and wool, which is applied in chemical instruments and methods, textile industry wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problem of metal ions entering water, achieve saving usage, obvious effect, and targeted treatment strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Prepare solution according to the method of content of the invention (1) and be acid mordant red S-80 dyestuff 0.2g, add sulfuric acid 1g, glacial acetic acid 1g, leveling agent 0.5g, penetrating agent 0.5g, use organic polymer flocculant Flocculate it, add 0.18g of flocculant and 0.035g of coagulant aid, dilute the total volume of the solution to 1000ml, stir at room temperature, and the dye removal rate after filtering through qualitative filter paper is 96.67%. The dye concentration in the filtrate is 6.7mg / L, pH: 5, dynamic adsorption with 120 mesh activated carbon at room temperature, flow rate: 12.8BV / h, treatment capacity is 538BV, and the removal rate of dye is further increased to 100%.

Embodiment 2

[0036]Embodiment 2: Prepare the solution according to the method of the content of the invention (1) and be Lanner free red 2B dyestuff 0.1g, add ammonium sulfate 1g, glacial acetic acid 1g, Abaig SET0.5g, Abaiger FFA0.5g, use organic high Molecular flocculant was used to flocculate it, adding 0.13g flocculant and 0.02g coagulant aid, the total volume of the solution was diluted to 1000ml, pH: 6, stirred at room temperature, and the dye removal rate was 98.42% after filtering through qualitative filter paper. The dye concentration in the filtrate is 1.6mg / L, and it is dynamically adsorbed by 120 mesh activated carbon at room temperature, the flow rate is 12.8BV / h, the treatment capacity is 321BV, and the removal rate of the dye is further increased to 100%.

Embodiment 3

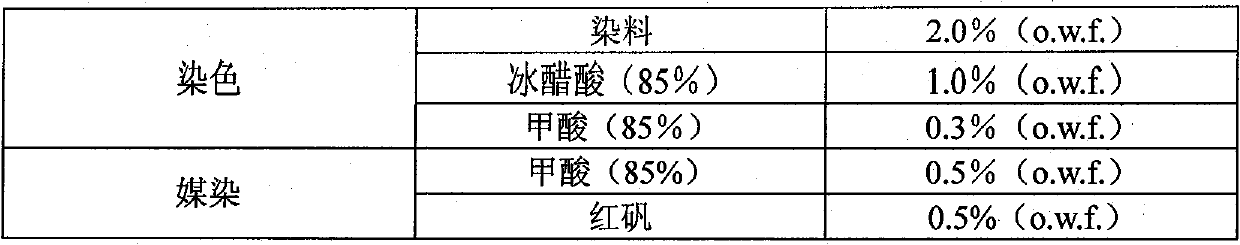

[0038] Table 1 Dyeing prescription of acid mordant dye (bath ratio 1:30)

[0039]

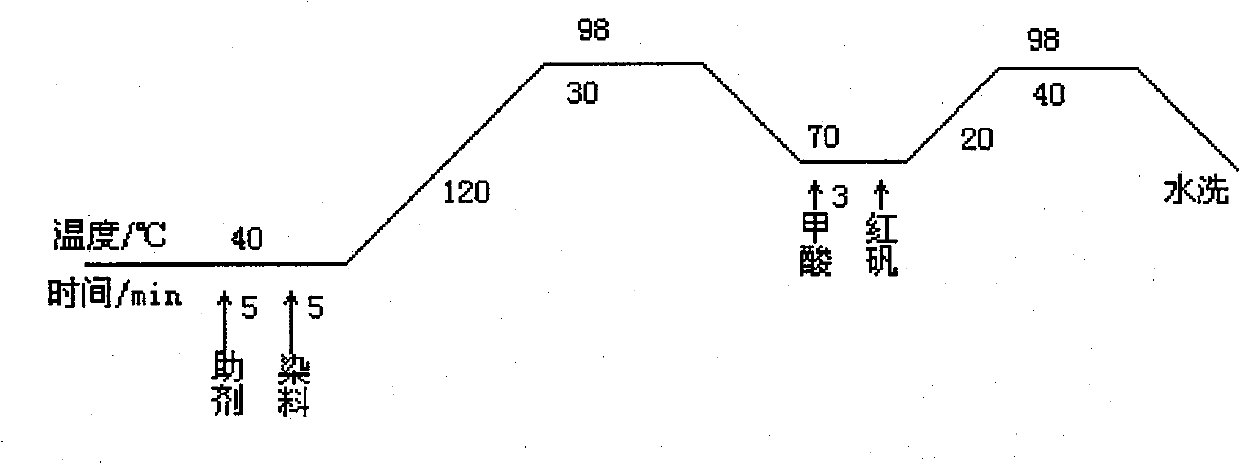

[0040] Acid mordant dyeing process:

[0041]

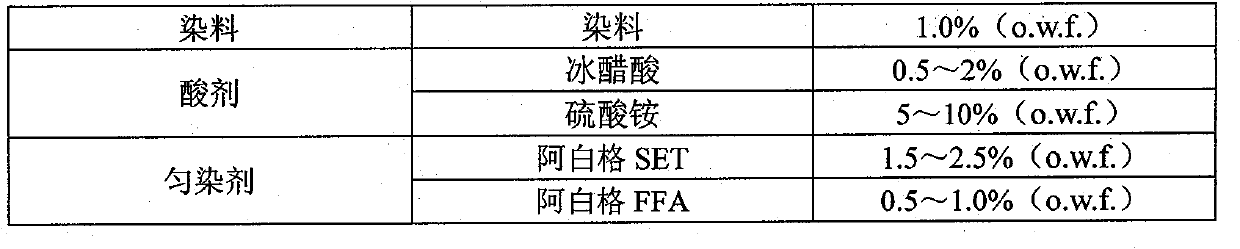

[0042] Table 2 Dyeing prescription of Lanna free dye (bath ratio 1:30)

[0043]

[0044] Lanna free and easy dyeing process:

[0045]

[0046] According to the dyeing prescription and process of acid mordant dyes and Lanner free dyes, the wool fabric is dyed with acid mordant dyes and Lanner free dyes with deionized water as the medium. Collect dyeing wastewater, according to the method of embodiment 1 and 2, the dyeing wastewater collected is flocculated, separated and adsorbed, wherein the separation and adsorption conditions are the same as the content of the invention (3) and (4); then replace deionized water with dyed wastewater after treatment As the dyeing medium, dyeing with reused water is carried out according to the same dyeing prescription and process, and the results are shown in Table 3-Table 4:

[0047] Table 3 The reu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com