Temperature-compensation circuit for primary side feedback system and method of isolated power converter

A technology of temperature compensation circuit and power converter, which is applied in the direction of output power conversion devices and electrical components, and can solve the problem of different output voltages of isolated power converters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

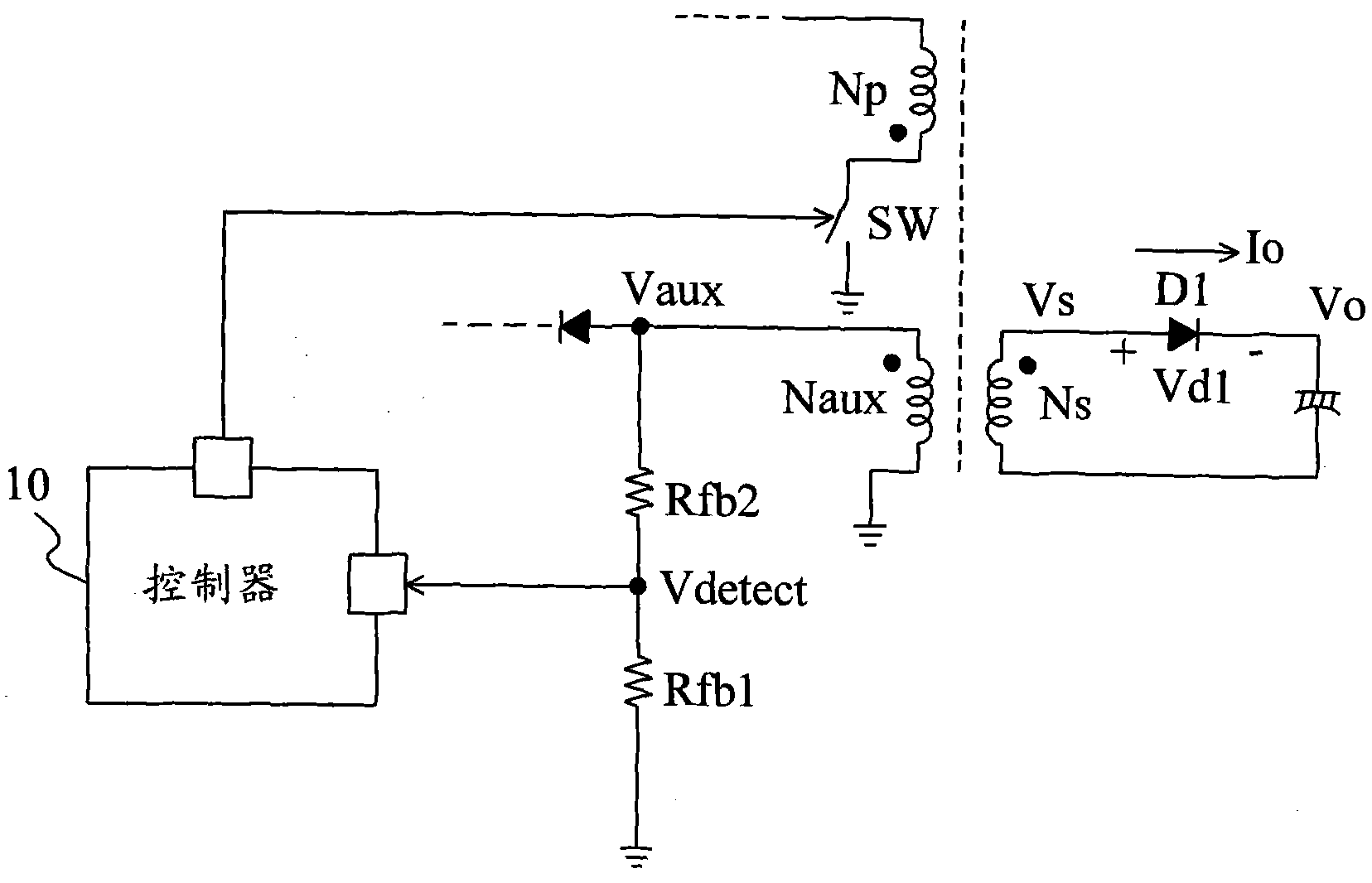

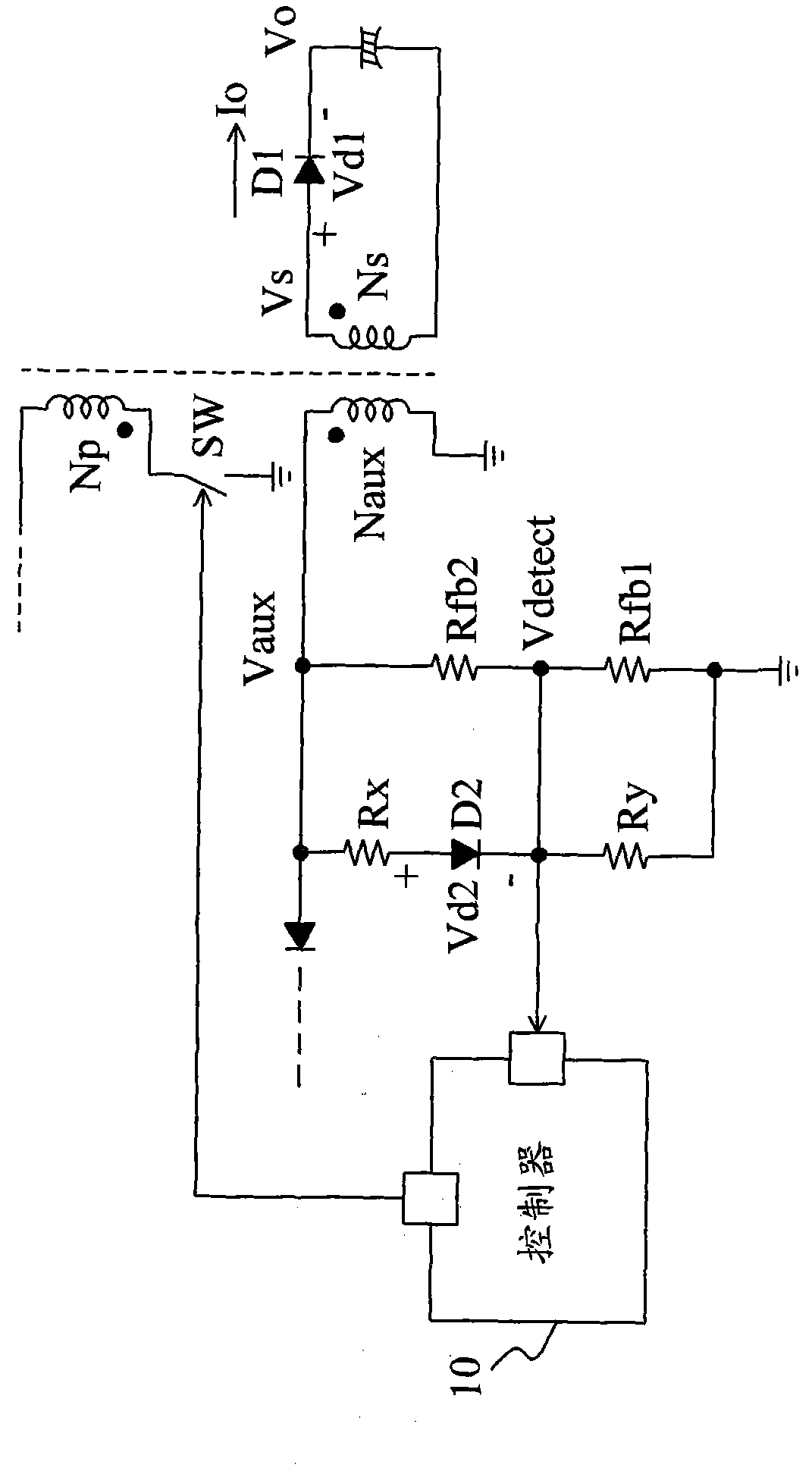

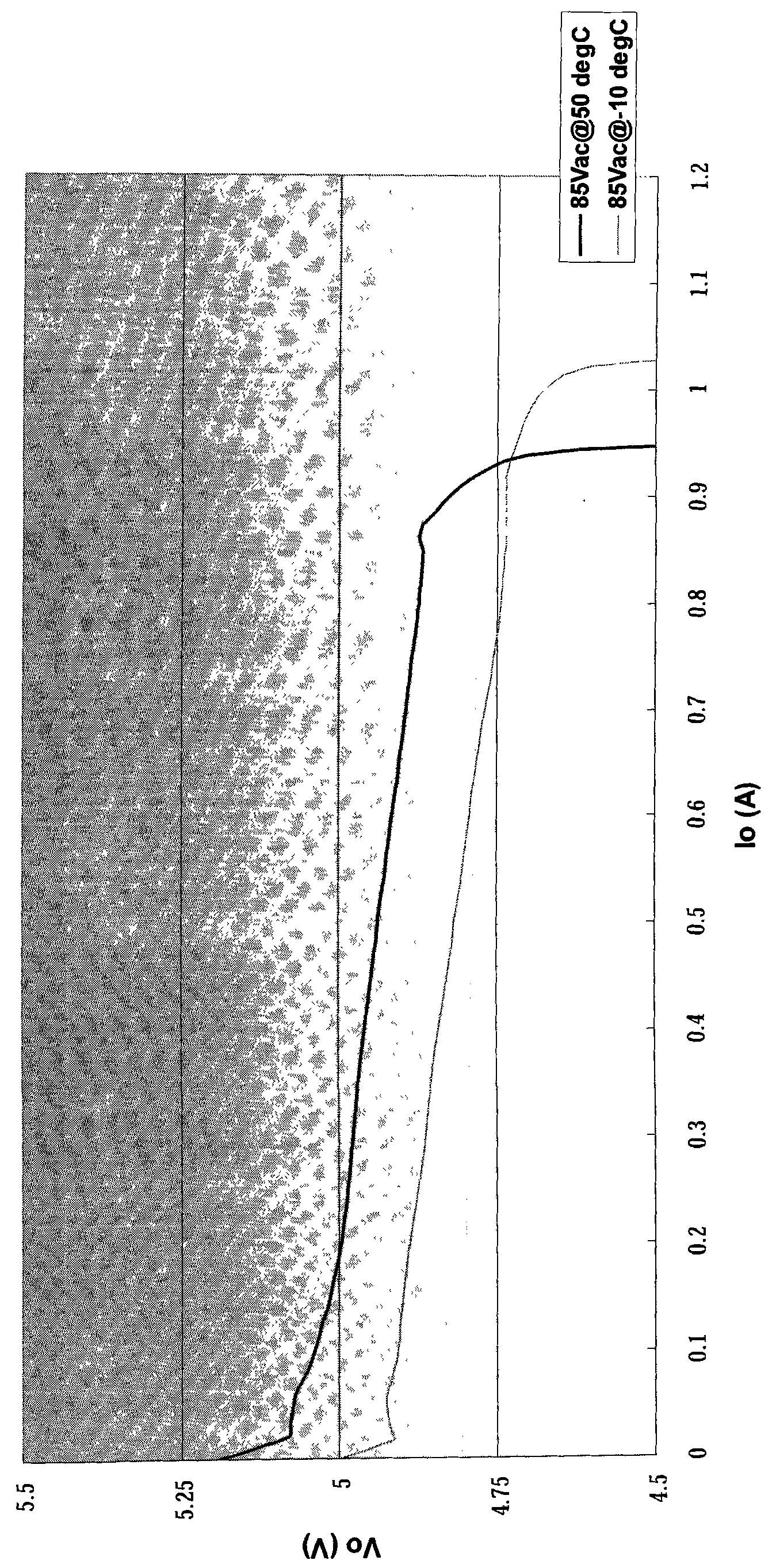

[0015] figure 2 is an embodiment of the present invention. The feedback circuit uses a resistor divider to divide the induction voltage Vaux of the auxiliary coil Naux to generate a feedback voltage Vdetect at the feedback terminal Vdetect. The resistor divider includes a resistor Rfb2 connected between the auxiliary coil Naux and the feedback terminal Vdetect , and the resistor Rfb1 is connected between the feedback terminal Vdetect and the ground terminal. The compensation diode D2 is connected between the auxiliary coil Naux and the feedback terminal Vdetect. Preferably, it has the same temperature characteristics as the output diode D1. For example, the forward bias voltages Vd1 and Vd2 of the two diodes D1 and D2 have negative temperature coefficients. , For example, Vd1 and Vd2 each decrease by 2mV for every 1°C increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com