Shooting hole blasting combined spacer

A combined and spacer technology, applied in blasting and other directions, can solve the problems of inability to closely match the shape of the blasting hole, complicated structure, low efficiency, etc., and achieve the effects of low production cost, safe and reliable construction, and accurate spacing position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

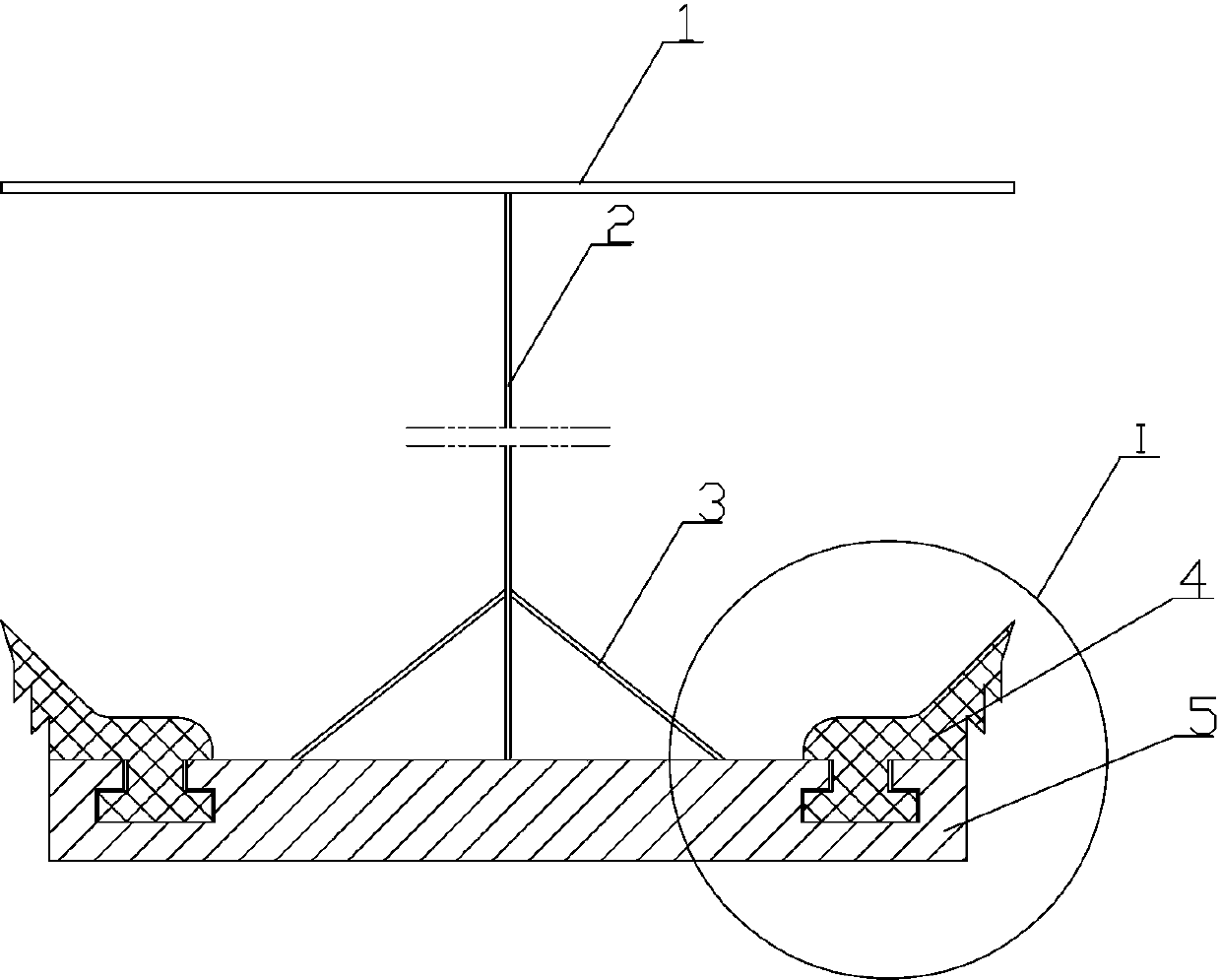

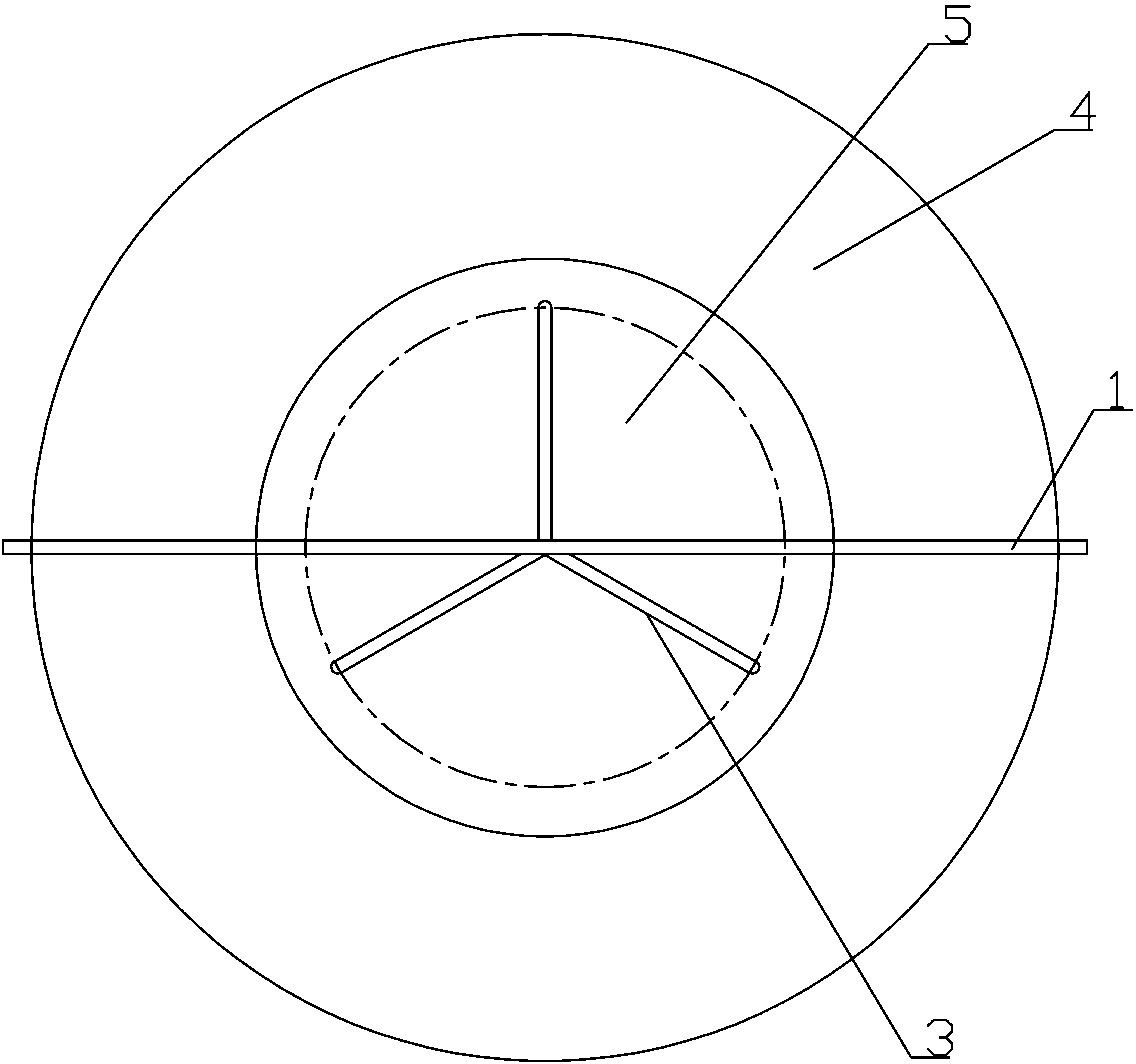

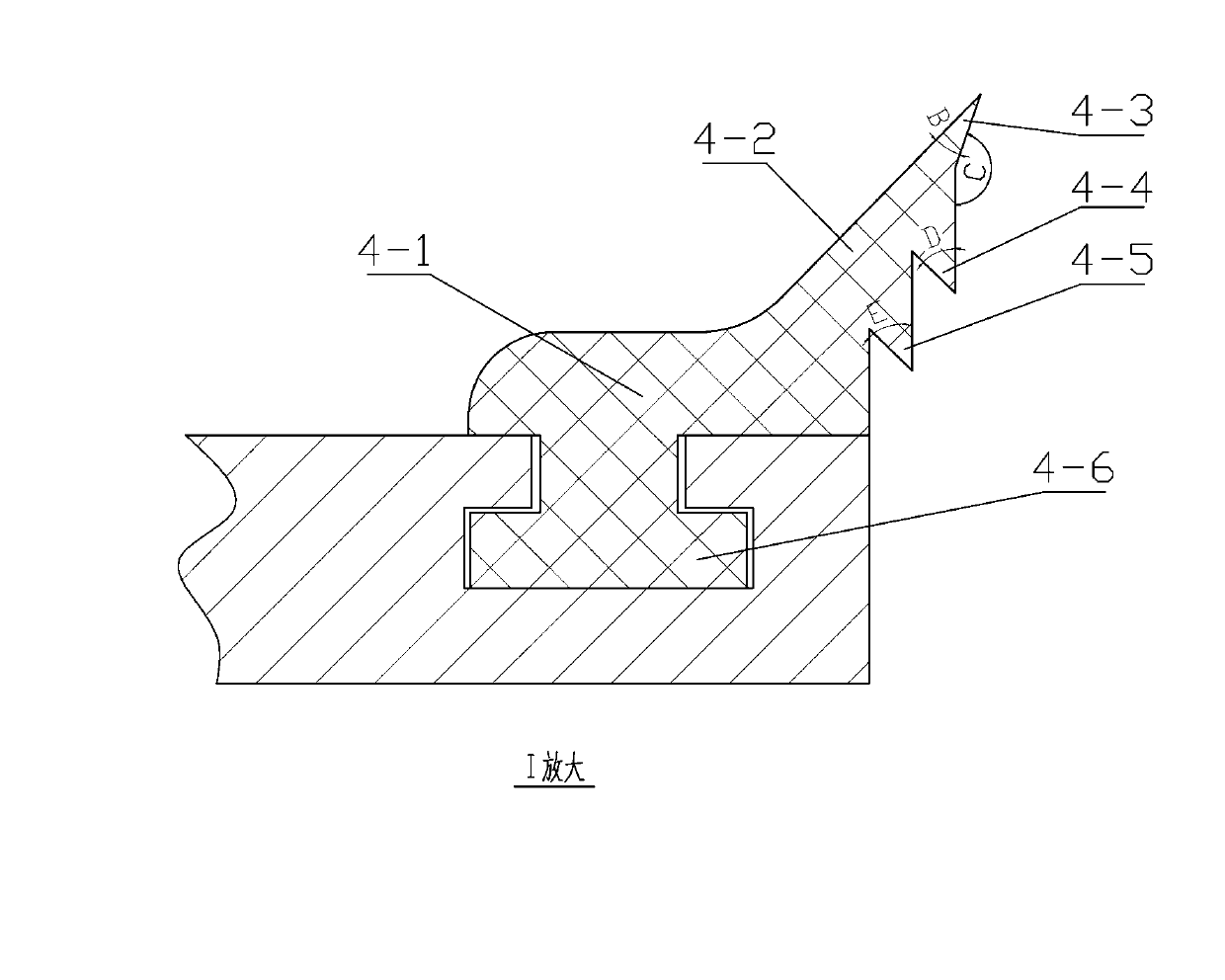

[0025] Such as figure 1 Shown: the blast hole blasting combined type spacer of the present invention is characterized in that by disc bottom plate 5, the rubber sealing ring 4 that is connected with this disc bottom plate 5, is connected with described disc bottom plate 5 circumferential upper surface A group of balance suspension ropes 3, a load-bearing stay rope 2 connected with this group of balance suspension ropes 3, and an orifice pole 1 connected with this load-bearing stay rope 2. The load-bearing stay rope 2 is provided with There is a scale scale line. During manual operation, the spacer is moved down in the blast hole, and the scale scale line shows the depth value moved down. The disc base plate 5 is provided with a circumferential T-shaped groove. This disc base plate 5 can be It is made of waste wood, bamboo and other materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com