Injection molded product and method for producing the same

A technology of injection molding and manufacturing method, used in chemical instruments and methods, synthetic resin layered products, decorations, etc., can solve the problems of poor three-dimensional effect of patterns on decorative films, and achieve the effect of good overall appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

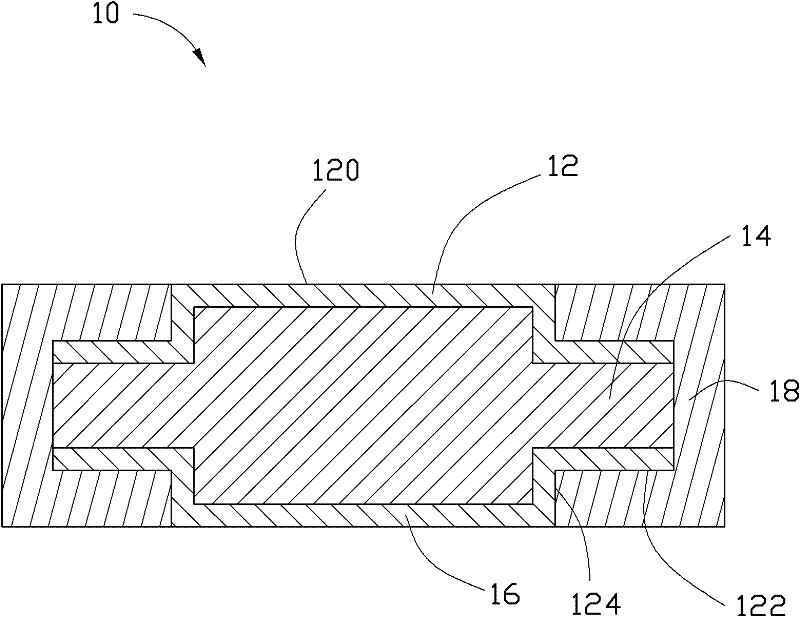

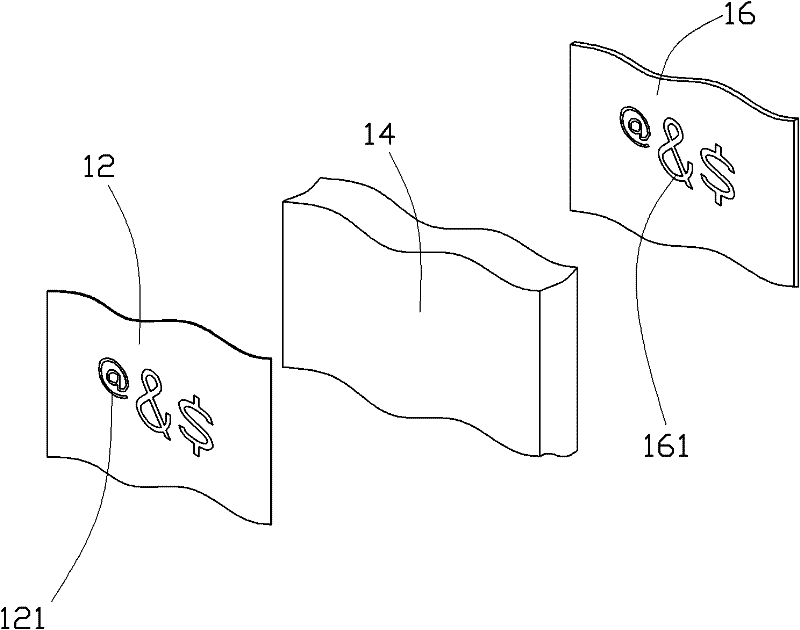

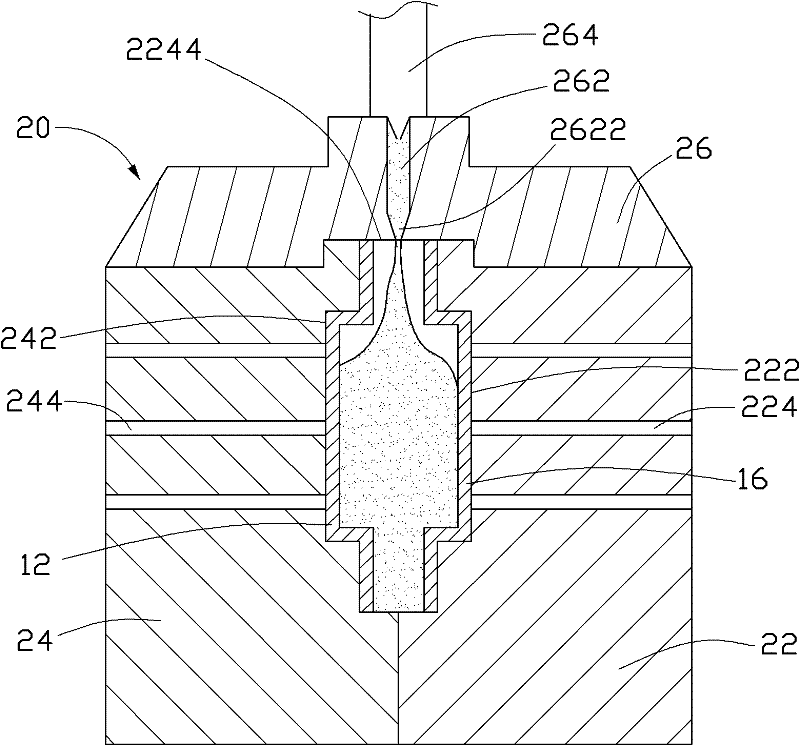

[0043] see figure 1 and figure 2 , the preferred embodiment of the injection molded product of the present invention is described by taking a housing 10 as an example, such as a mobile phone housing. The casing 10 includes a first decoration layer 12 , a middle layer 14 , and a second decoration layer 16 .

[0044] Both the first decoration layer 12 and the second decoration layer 16 are formed by printing patterns on a film with a certain degree of transparency, and the film can be made of resin, glass, fiber or polymer material. The first decoration layer 12 and the second decoration layer 16 are respectively located on opposite sides of the middle layer 14 . A first pattern 121 is formed on the first decoration layer 12 , and a second pattern 161 is formed on the second decoration layer 16 . The second pattern 161 has the same shape as the first pattern 121 and the position is aligned, that is, in the vertical projection direction of the second decoration layer 16 to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com