Method and equipment for simultaneously forming multiple high polymer thin bars by single screw machine barrel

A technology for polymer materials and molding equipment, which is applied in the field of single-screw barrel molding methods and equipment for simultaneous molding of multiple strands of thin rods of polymer materials, can solve the problems of lack of fluidity, application restrictions, poor fluidity, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but it will not constitute a limitation to the present invention.

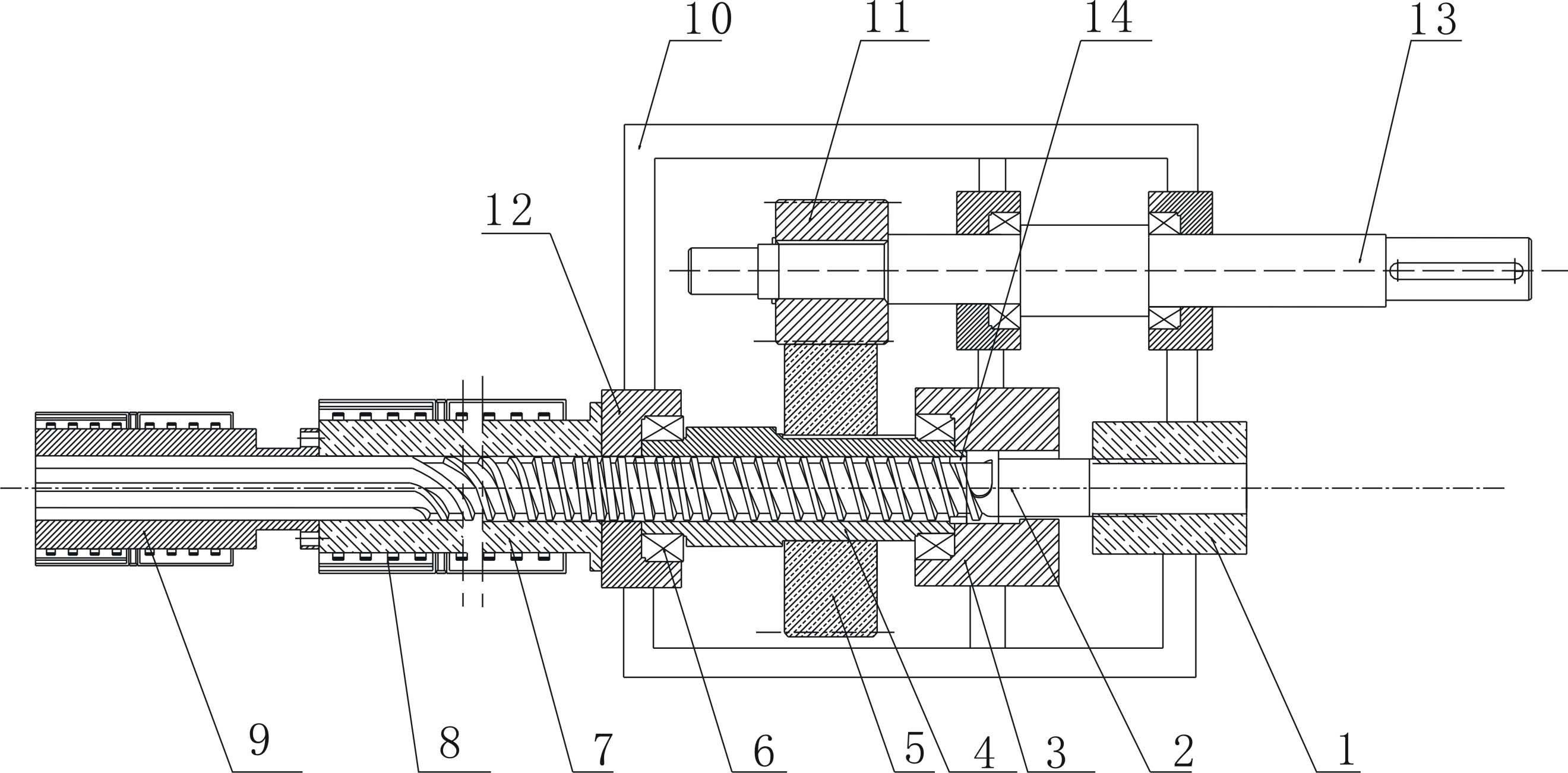

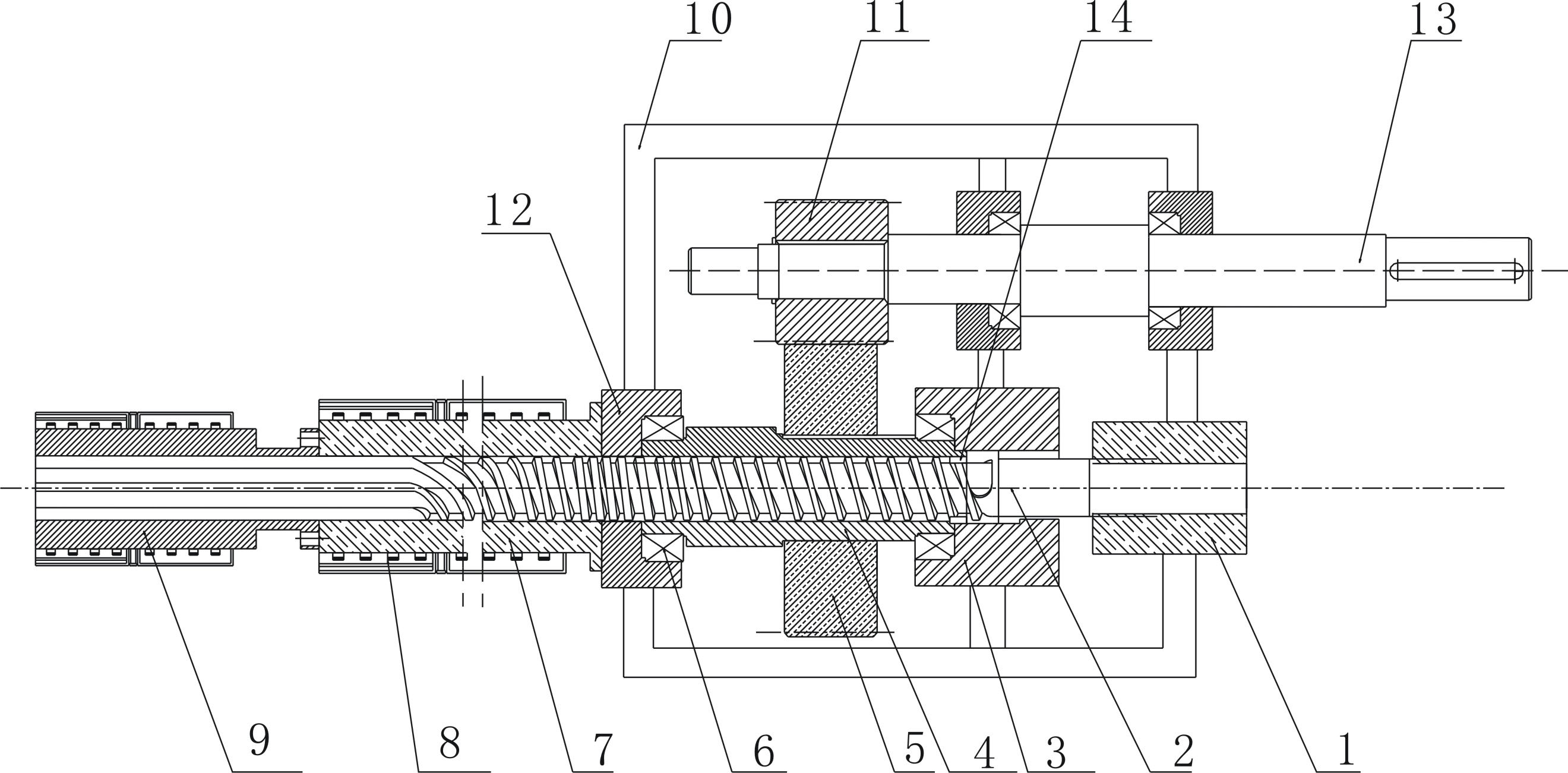

[0023] The forming equipment of the present invention mainly includes: screw positioning seat 1, screw rod 2, feeding seat 3, rotating barrel 4, gear 5, bearing 6, forming barrel 7, heater 8, homogenizing barrel 9, box body 10 , gear 11, bearing seat 12, power input shaft 13 and feeding ring 14, the screw 2 is fixed on the screw positioning seat 1, and the rotating barrel 4 is fixed on the box through the bearing 6, the feeding seat 3 and the bearing seat 12 respectively. On the body 10, the molding barrel 7 and the homogenizing barrel 9 are connected to each other through flanges and fixed on the bearing seat 12. The outer sides of the homogenizing barrel 9 and the molding barrel 7 are respectively equipped with heaters 8, and the rotating barrel 4. A feeding ring 14 is embedded in the raw material inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com