Angle steel tower of power transmission line

A technology for transmission lines and angle steel towers, applied in the field of angle steel towers, can solve problems such as inability to disassemble, transport, inconvenient installation, and single shape, and achieve the effects of no hidden safety hazards, rich and beautiful appearance, and good windproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

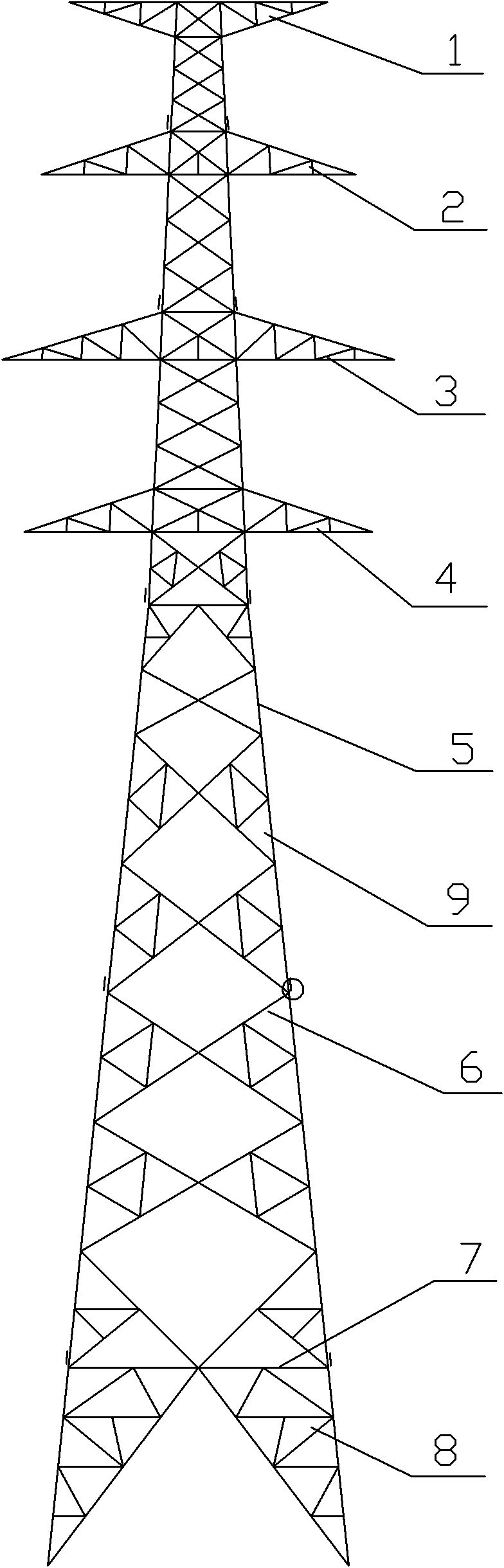

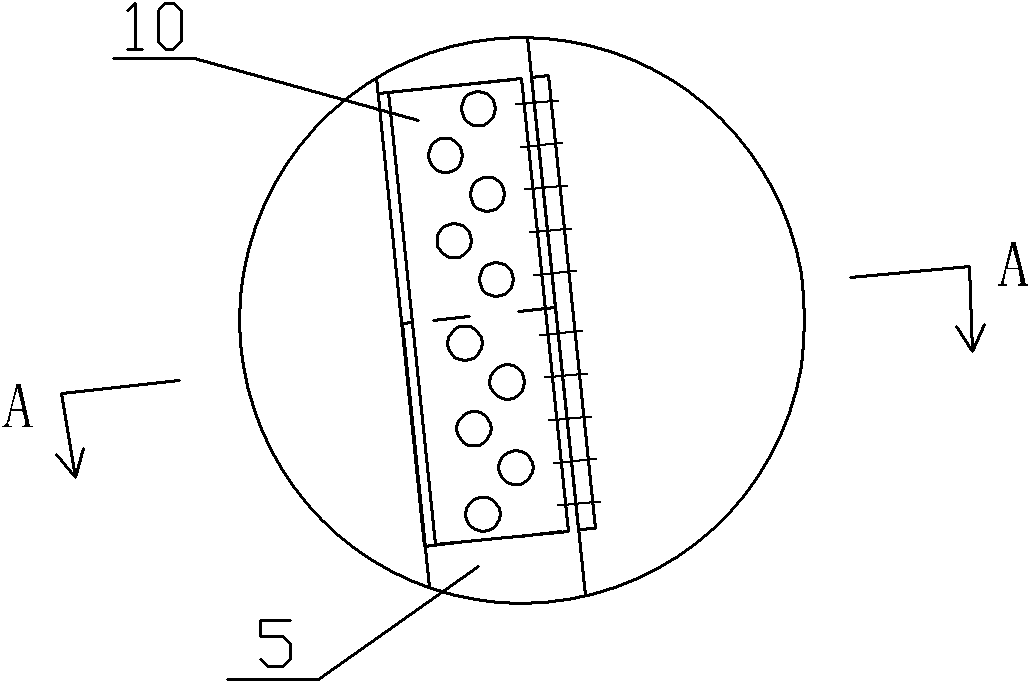

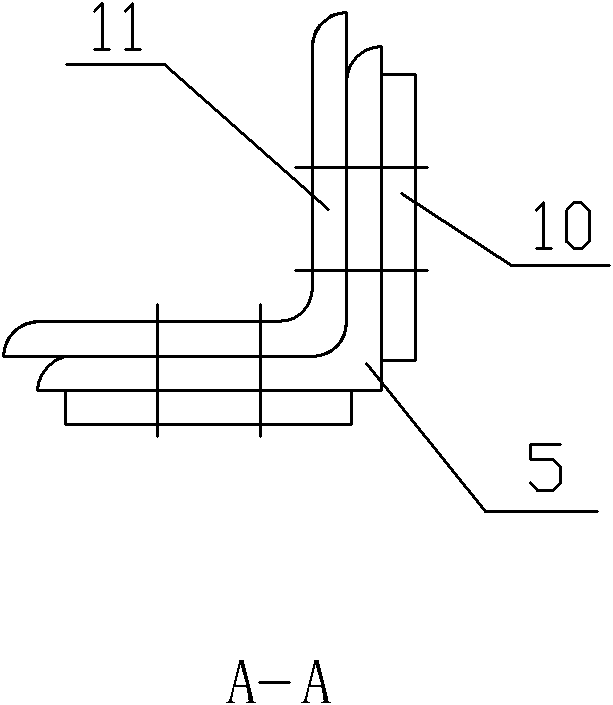

[0013] Refer to the attached figure 1 to attach Figure 5 The transmission line angle steel tower of the present invention will be described in detail below.

[0014] The angle steel tower of the transmission line of the present invention has a structure comprising a tower body 9 and a tower leg 8, and the tower body 9 is sequentially provided with a ground wire support 1, an upper wire cross arm 2, a middle wire cross arm 3 and a lower wire cross arm 4. The middle conductor cross arm 3 is slightly longer than the upper conductor cross arm 2 and the lower conductor cross arm 4. The tower body 9 is formed by lapping tower sections with variable slopes. The tower body 9 includes tower Column 5, oblique bar 6 and cross bar 7, the cross-section of described tower body 9 is quadrilateral, wherein four tower columns 5 are respectively positioned at the corner of quadrilateral, described tower column 5 and cross bar 7, oblique bar 6 Bolted connection via connecting plate.

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com