High-safe-reliability nuclear-grade seal gasket

A sealing gasket and reliable technology, which is applied in the field of sealing gaskets, can solve problems such as troublesome molding process and poor sealing effect, and achieve the effect of simple molding and better sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

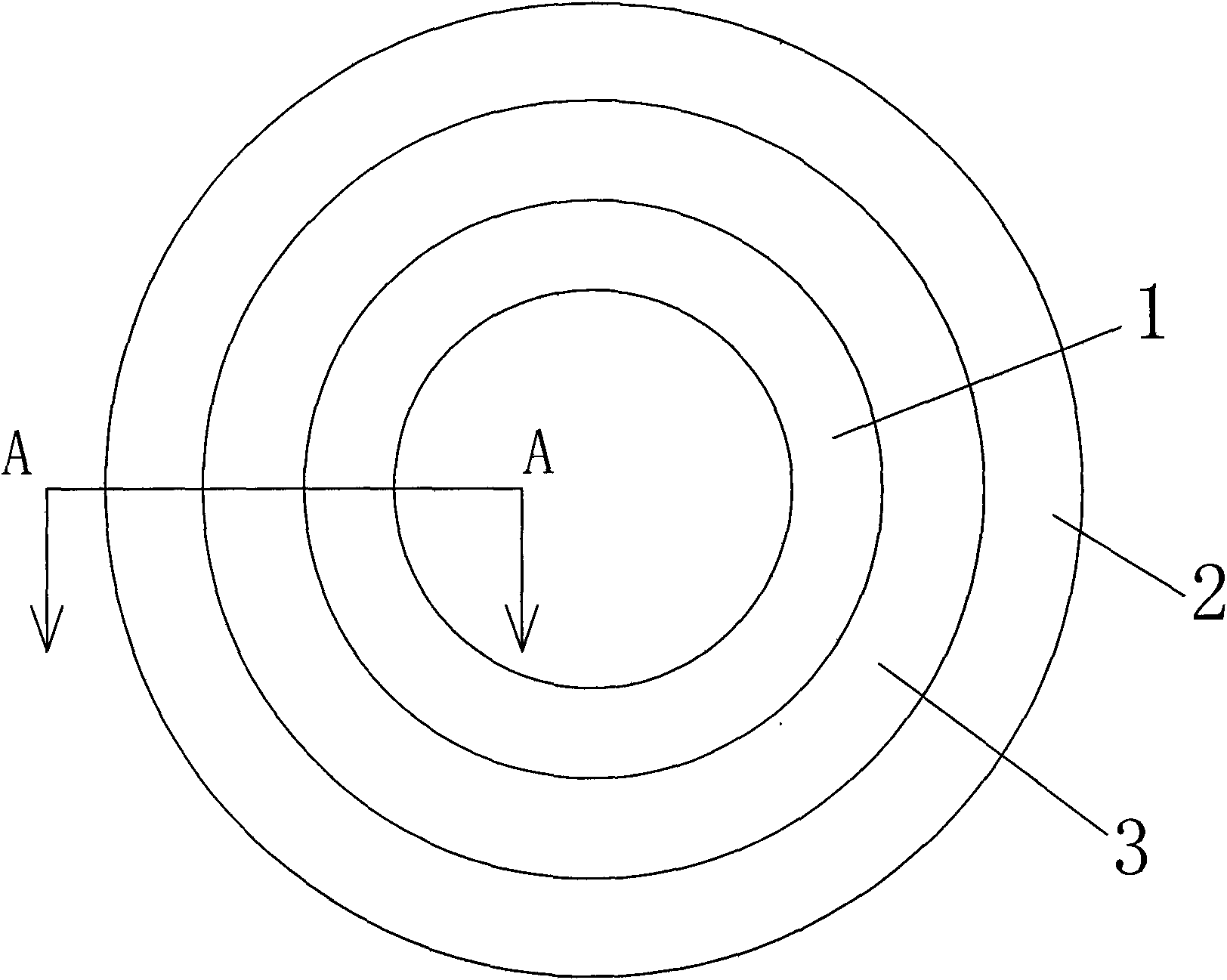

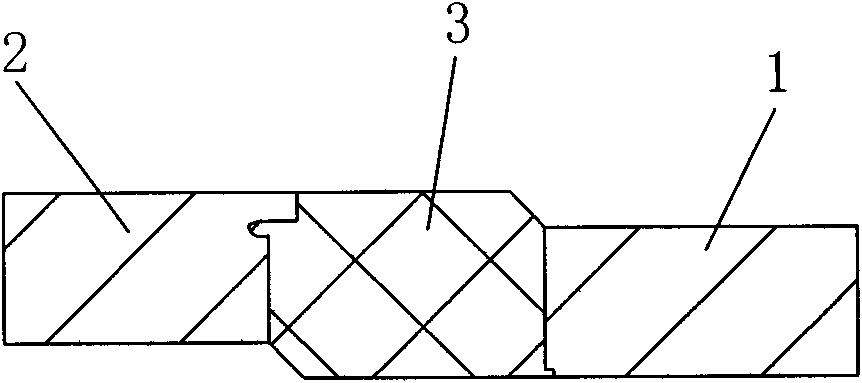

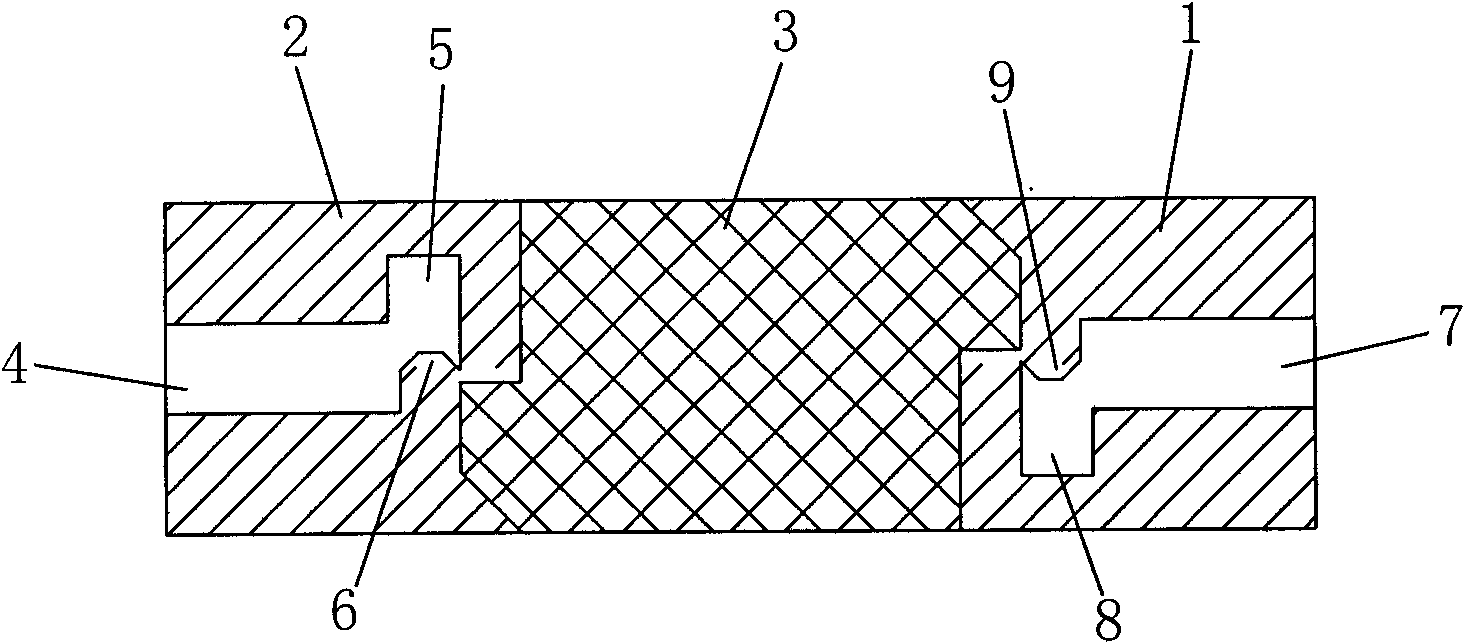

[0020] refer to figure 1 , image 3 , a high-safety nuclear-grade sealing gasket, including a metal inner ring 1 and a metal outer ring 2, and a flexible graphite ring 3 sandwiched between the metal inner ring 1 and the metal outer ring 2, the metal inner ring The thickness of the ring 1 is equal to the thickness of the metal outer ring 2, and the metal inner ring 1 is flush with the metal outer ring 2, and the flexible graphite ring 3 and the metal inner ring 1, Metal outer rings 2 are even;

[0021] The outer edge of the metal outer ring 2 has a circle of outer deformation grooves extending inward, and the inner edge of the metal inner ring 1 has a circle of inner deformation grooves extending outward. In this embodiment, the outer deformation groove includes an outer flat groove 4 extending inward from the outer edge of the metal outer ring, and an upwardly folded outer tenon groove 5 located at the end of the outer flat groove 4. The end of the outer flat groove 5 has a...

Embodiment 2

[0026] refer to figure 1 , Figure 4 , refer to figure 1 , image 3 , a high-safety nuclear-grade sealing gasket, including a metal inner ring 1 and a metal outer ring 2, and a flexible graphite ring 3 sandwiched between the metal inner ring 1 and the metal outer ring 2, the metal inner ring The thickness of the ring 1 is equal to the thickness of the metal outer ring 2, and the metal inner ring 1 is flush with the metal outer ring 2, and the flexible graphite ring 3 and the metal inner ring 1, Metal outer rings 2 are even;

[0027] The outer edge of the metal outer ring 2 has a circle of outer deformation grooves 10 stretching inward, and the inner edge of the metal inner ring 1 has a circle of inner deformation grooves 11 extending flat outward.

[0028] When forming, the flexible graphite ring 3 is first placed between the metal inner ring 1 and the metal outer ring 2, and then pressure is applied to it to cause a certain amount of deformation of the metal inner ring 1 ...

Embodiment 3

[0031] refer to figure 1 , Figure 5 , a high-safety nuclear-grade sealing gasket, including a metal inner ring 1 and a metal outer ring 2, and a flexible graphite ring 3 sandwiched between the metal inner ring 1 and the metal outer ring 2, the metal inner ring The thickness of the ring 1 is equal to the thickness of the metal outer ring 2, and the metal inner ring 1 is flush with the metal outer ring 2, and the flexible graphite ring 3 and the metal inner ring 1, Metal outer rings 2 are even;

[0032] The outer edge of the metal outer ring 2 has a circle of outer deformation grooves extending inward, and the inner edge of the metal inner ring 1 has a circle of inner deformation grooves extending outward. In this embodiment, the outer deformation groove includes an outer flat groove 4 stretched inward from the outer edge of the metal outer ring, an outer tenon groove 5 folded down at the end of the outer flat groove 4, The end of the outer flat groove 5 has an upwardly prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com