Large-load actuating cylinder control sliding lock

An actuating cylinder, large load technology, applied in the direction of transmission, chassis, belt/chain/gear, etc., can solve the problem of unable to meet the large load locking, and achieve the effect of reliable retraction and unlocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

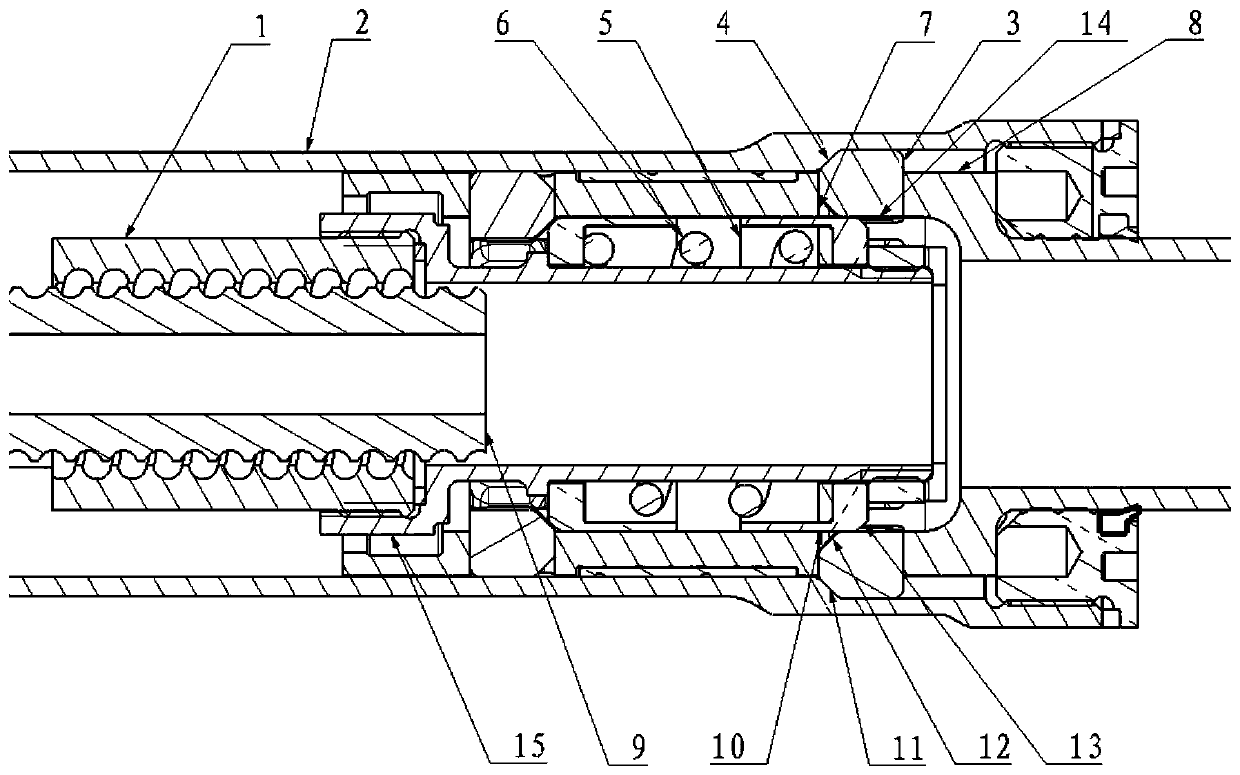

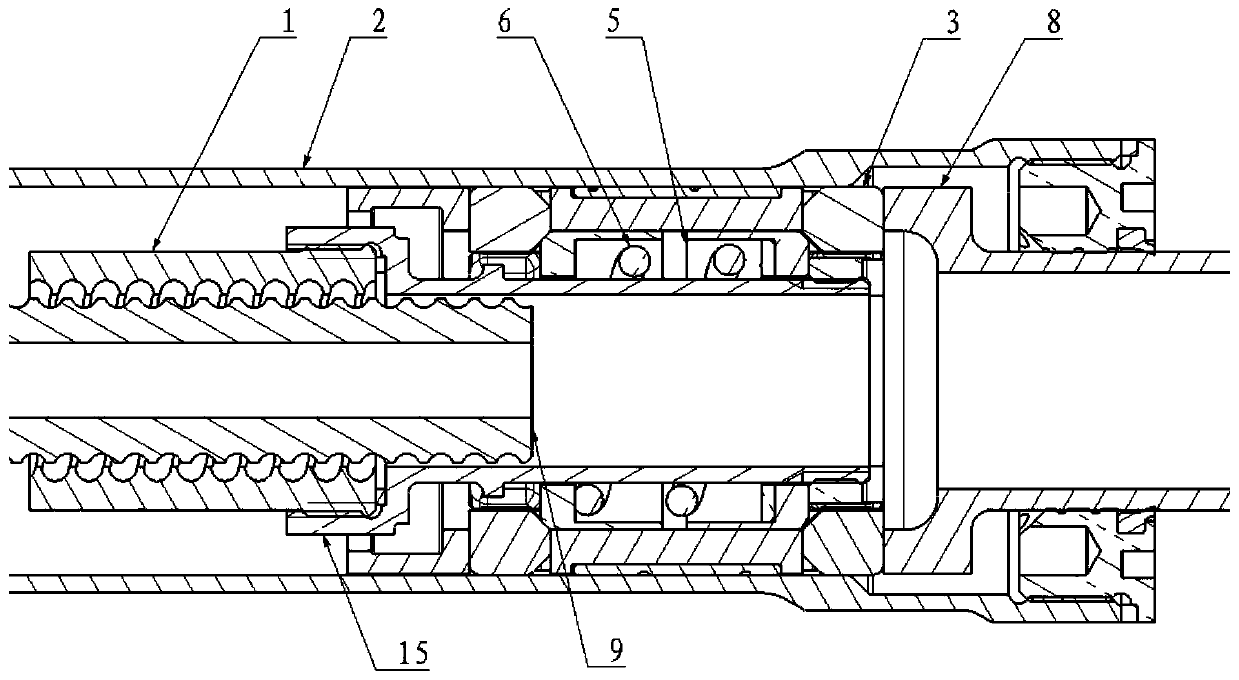

[0012] refer to figure 1 , figure 2 . In the preferred embodiment described below, a large-load actuating cylinder control slip lock includes: assembled in the actuating cylinder, the piston cylinder 2 providing the locking groove and the spring 6 providing the locking force, through the spring sleeve The cylinder 15 is assembled with the lead screw nut 1 and the lead screw 9 in the actuator cylinder, the sliding sleeve 5 assembled on the outer ring surface of the spring sleeve 15, the sliding block 3 radially supported by the sliding sleeve 5, and the guide groove 7 driving the sliding block 3 The moving piston rod 8 is characterized in that: the slider 3 is installed in the guide groove 7 of the piston rod 8, the slider 3 passes through the locking slope 11, leans against the axial locking groove slope 4 of the inner wall of the piston barrel 2 and The outer ring surface 10 of the sliding sleeve 5 is on the tail end surface, and the rear end of the slider 3 abuts against ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com