Compression type automatic packaging garbage can

A garbage can and compression technology, which is applied in the direction of garbage cans, garbage collection, household appliances, etc., can solve the problems of inability to compress garbage, ineffective use of garbage can space, unhygienic and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

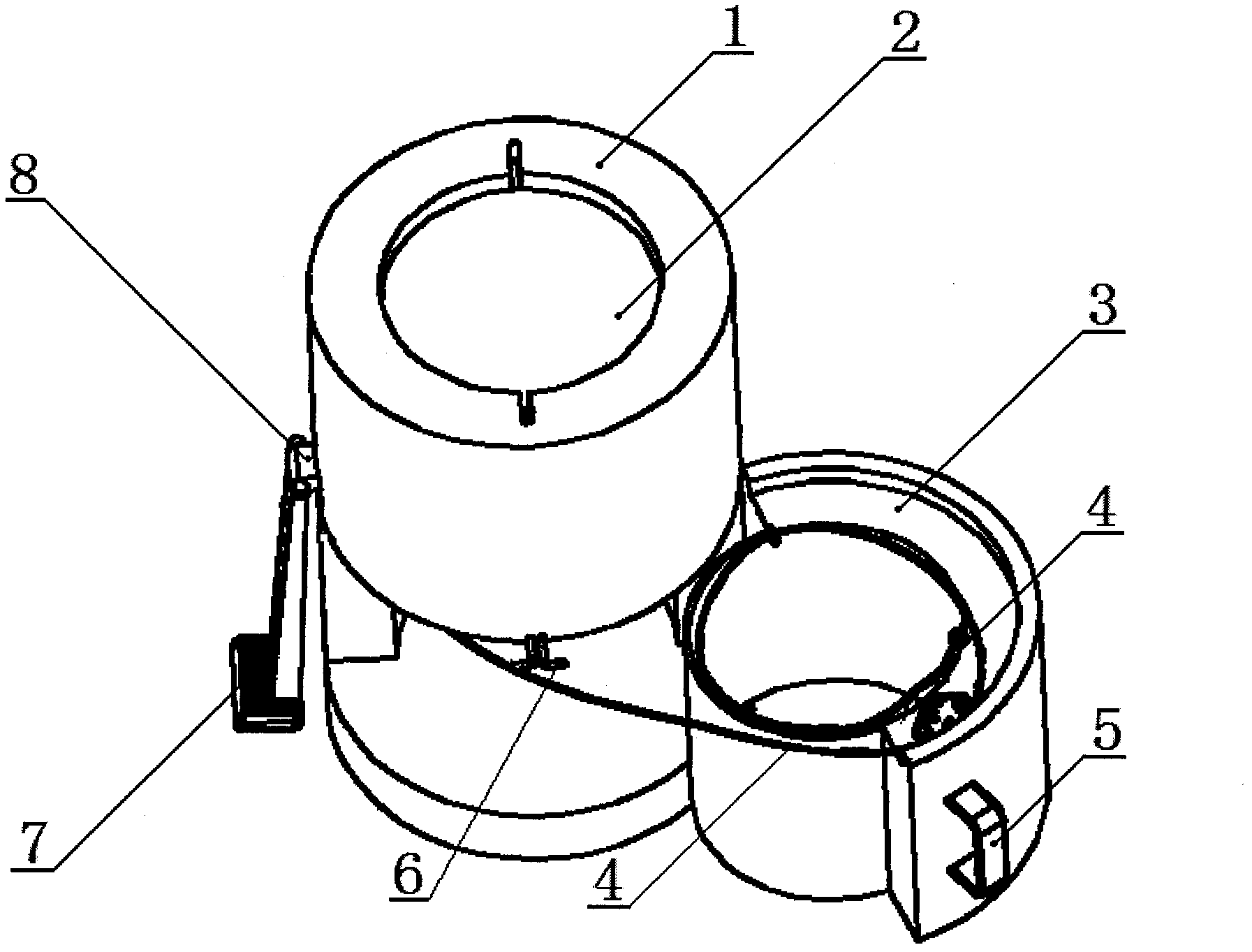

[0017] like figure 1 It is a structural schematic diagram of the compressed self-packing garbage can, which is mainly composed of an outer cylinder, an inner cylinder, movable leaves, a compression mechanism, and a sealing device.

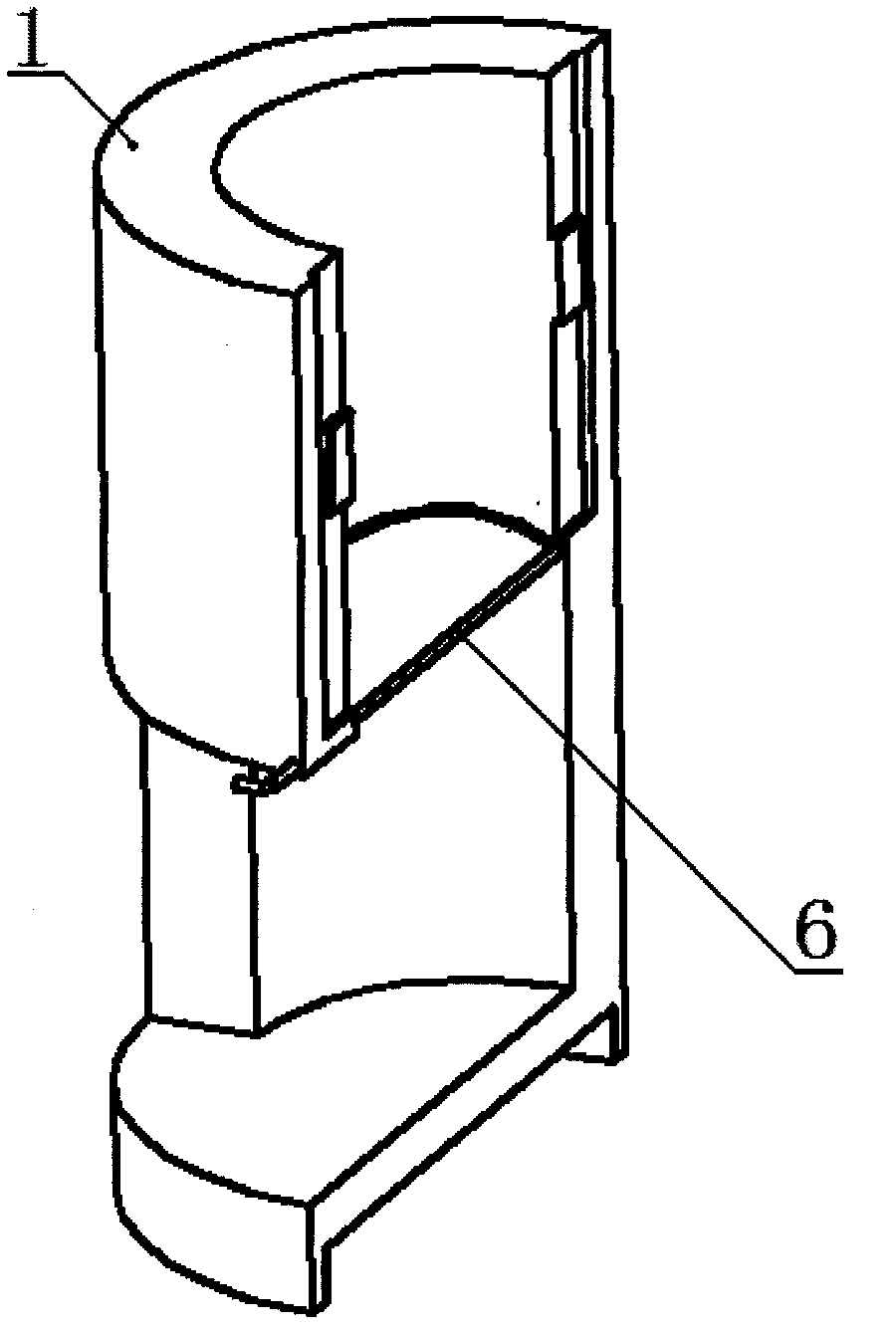

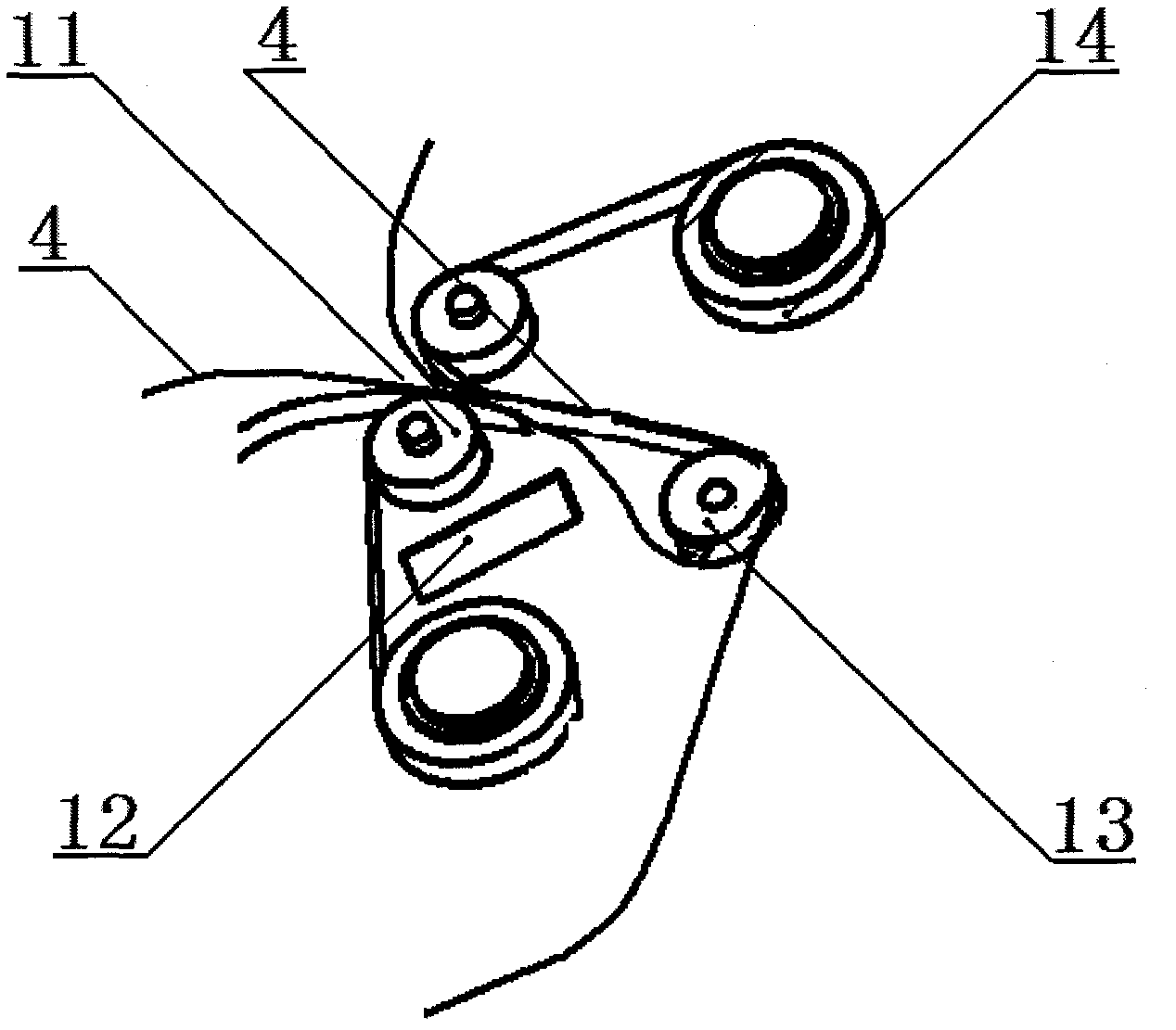

[0018] like figure 2 It is a schematic diagram of the position where the movable leaf and the rotating shaft are located in the middle of the inner cylinder. The movable leaf is composed of two semicircular movable blades and is connected to a rotating shaft (6). The rotating shaft leads to the Outside the wall of the outer cylinder, the movable flap is located in the middle of the inner cylinder (3), and the inner cylinder is divided into an upper layer of the inner cylinder and a lower layer of the inner cylinder, and the movable flap becomes the bottom of the upper layer of the inner cylinder. When there is enough garbage on the movable leaf, turn the rotating shaft located outside the outer cylinder wall to rotate the semicircular movable lea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap