Operating platform assembly of sawing machine

An operation platform and assembly technology, which is applied in the direction of circular saws, sawing equipment, wood processing equipment, etc., can solve the problems of wood impact, a large amount of dust and sawdust, and polluted air environment, so as to prevent wood from retreating and have strong adaptability , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

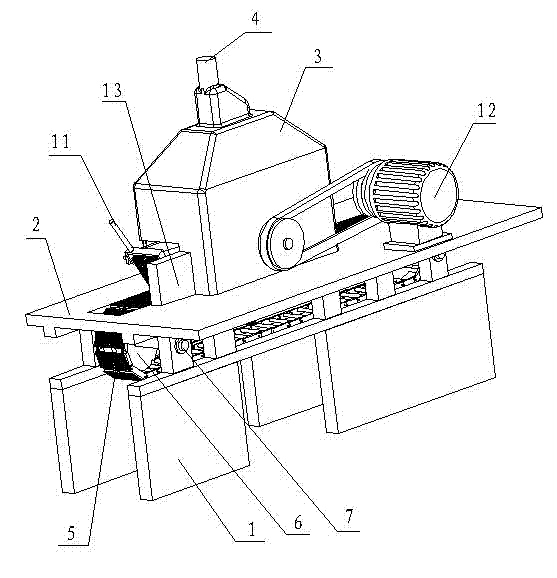

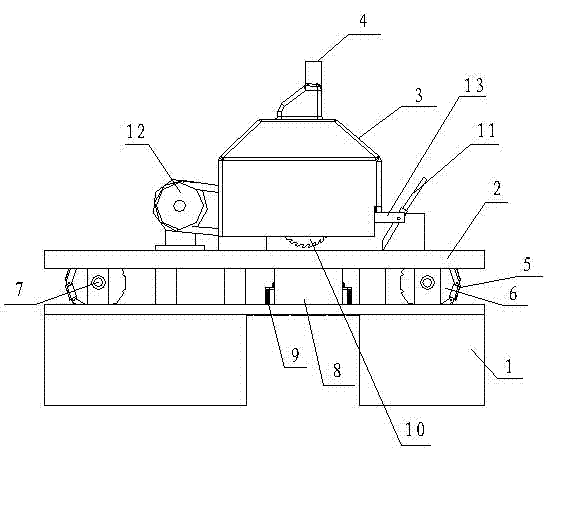

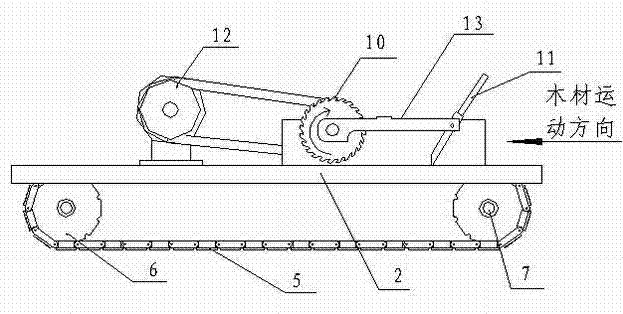

[0019] like figure 1 - Shown in 4, a kind of operation platform assembly of sawing machine comprises support 1, and the top of support 1 is provided with operation platform 2.

[0020] The operation platform 2 has a rectangular hole, and the bottom of the rectangular hole is equipped with a conveyor belt 5, and the two ends of the conveyor belt 5 inside are equipped with a sprocket 6, and the sprocket 6 is installed on the support 1 through the sprocket shaft 7, and through the rotation of the sprocket 6, thereby The movement of the wood placed on the operating platform 2 is driven, so that the electric saw blade 10 performs sawing operation on the wood.

[0021] The upper part of the operating platform 2 is provided with a support frame 13, and the two ends of the support frame 13 are respectively equipped with a chainsaw blade 10 and a check card 11. , both sides of the non-return card 11 are provided with support shafts, and the support shafts pass through the mounting ho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap