Waterway cooling structure of back mould

A technology of cooling structure and water circuit, applied in the field of cooling structure of mold, can solve the problems of prolonging mold molding cycle, affecting product quality, unable to design cooling water circuit, etc., to achieve the effect of ensuring cooling and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

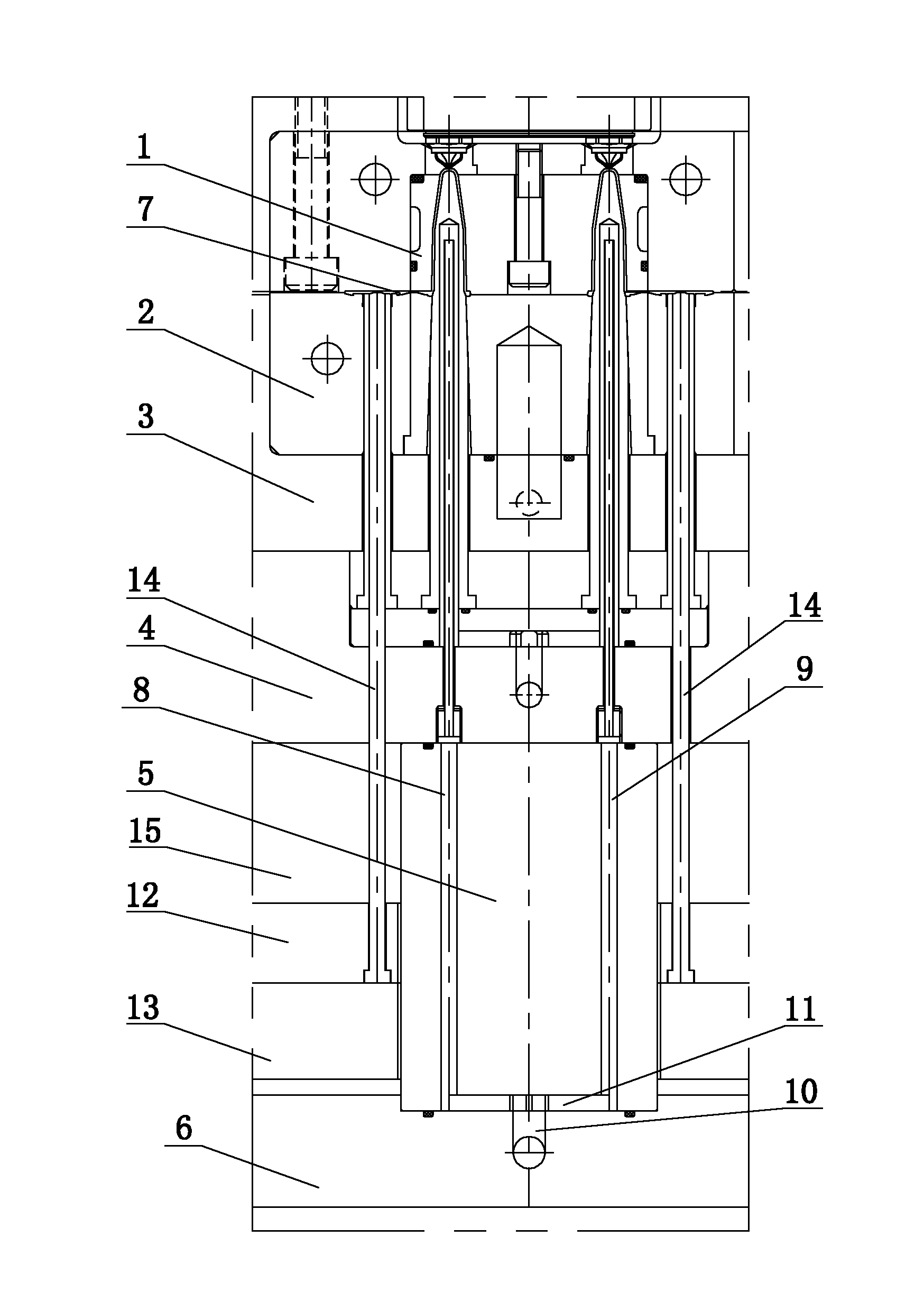

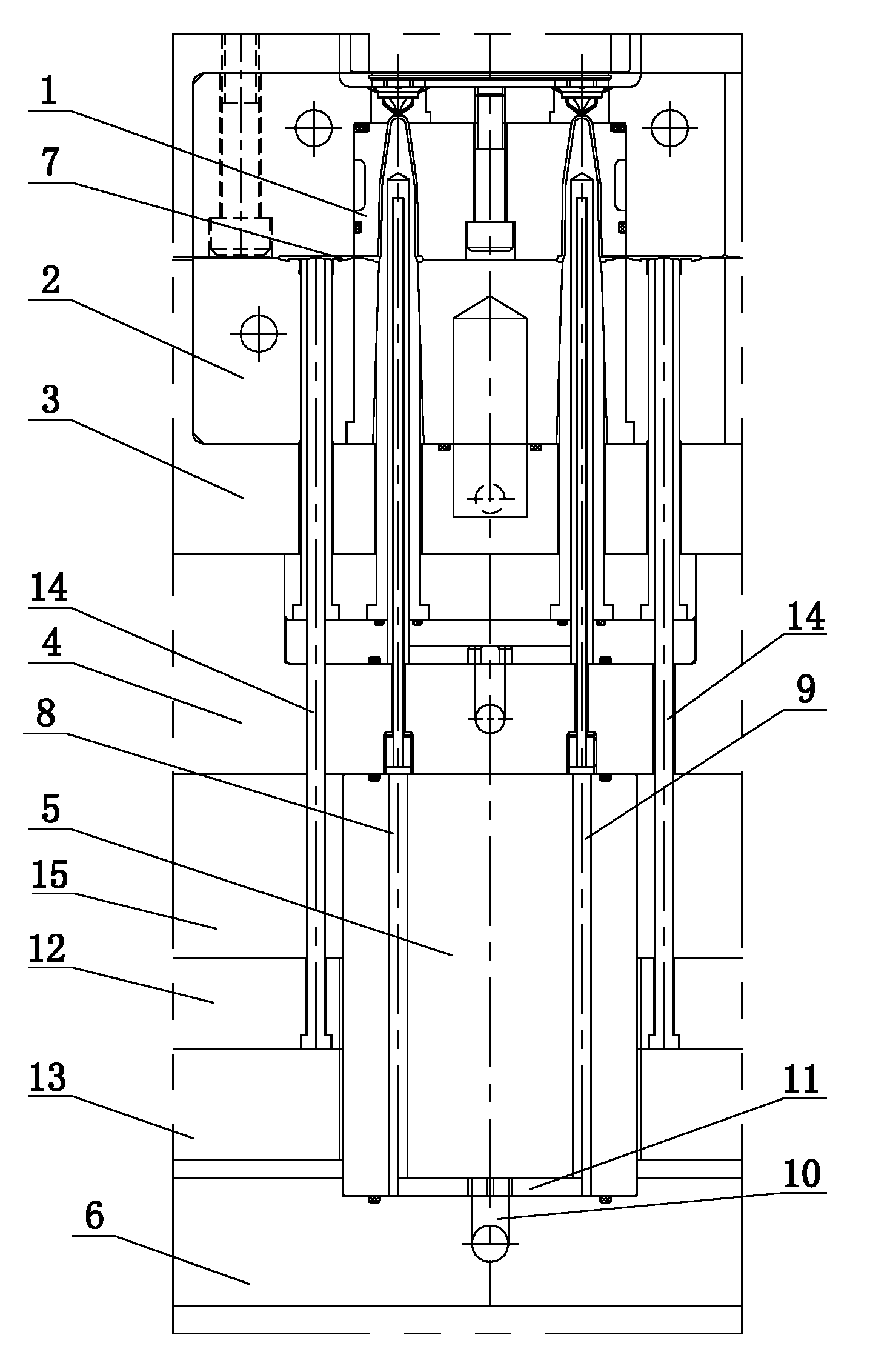

[0009] See figure 1 , which includes a front mold core 1, a rear mold core 2, a B plate 3, a backing plate 4, a support column 5, and a lower fixing plate 6. Formed product 7, the rear model core 2 is supported on the B plate 3, the B plate 3 is supported on the backing plate 4, the backing plate 4 is supported on the support column 5, the support column 5 is supported on the lower fixed plate 6, and the waterways 8 and 9 are from bottom to top After passing through the support column 5, backing plate 4, and B plate 3 in sequence, it goes deep into the interior of the rear model core 1, and the lower fixed plate 6 is provided with a water pipe channel 10, and the inner side of the water pipe channel 10 is connected to the bottom of the waterways 8, 9, specifically the waterways 8, The bottom between 9 is provided with a communication groove 11, and the communication groove 11 communicates with the water pipe passage 10; the outside of the water pipe passage 10 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com