Compound type self-rescuer

A self-rescuer and composite technology, applied in safety devices, mining equipment, earth-moving drilling, etc., can solve the problems of shortened protection time, waste, and short protection time, and achieve the effect of extending protection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

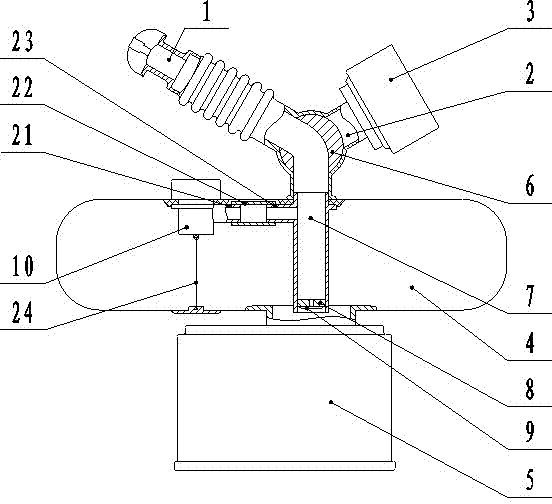

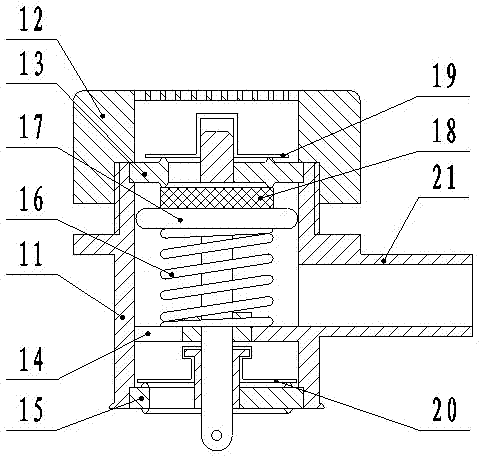

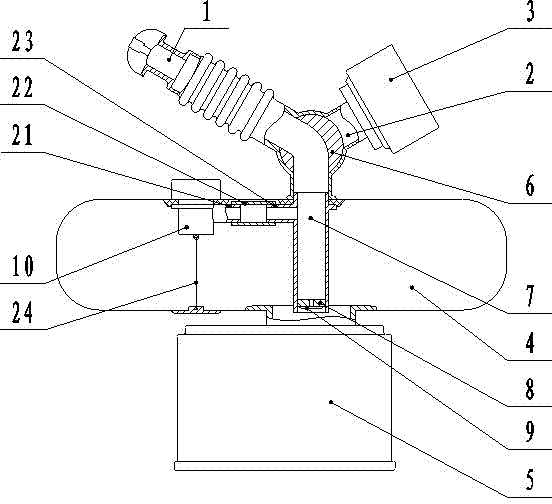

[0016] Such as figure 1 figure 2 As shown, the composite self-rescuer of the present invention includes a mouthpiece 1, a three-way joint 2, a filter absorber 3, an air bag 4, an oxygen generator 5, a switching valve 6 and a connecting body 7, and the structure of the three-way joint 2 is : There are three tubular interfaces connected to a hollow sphere, the switching valve 6 is installed in the hollow sphere of the three-way joint 2, the mouthpiece 1 is connected to one interface of the three-way joint 2, and the filter absorber 3 is connected to the three-way joint 2, the airbag 4 is connected to the last interface of the tee joint 2 through the connecting body 7, the connecting body 7 is located inside the airbag 4, the top of the airbag 4 is stuck on the upper part of the connecting body 7, the bottom of the airbag 4 is connected to the The oxygen generator 5 is connected, one end of the connector 7 is connected to the interface of the tee joint 2, the other end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com