Waterproof anti-oxidation insulating paint for power device

An anti-oxidation technology for power equipment, applied in anti-fouling/underwater coatings, primers, anti-corrosion coatings, etc., can solve the problems of poor waterproof and insulating properties, and achieve excellent protection effects, long protection time, and not easy yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

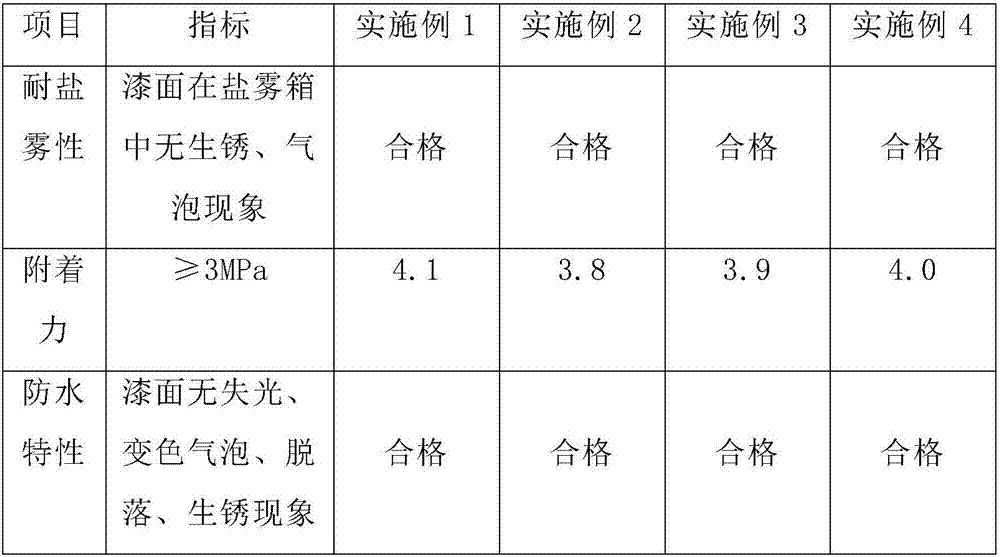

Examples

Embodiment 1

[0021] A waterproof and anti-oxidation insulating varnish for electric equipment, comprising a protective primer and a waterproof topcoat, the components of the protective primer are: 30 parts by mass of xylene, 30 parts of alkyd resin, 10 parts of aluminum powder slurry, china clay 10 parts, 3 parts of talcum powder, 2 parts of dibutyltin dilaurate, 1 part of silicon dioxide, 15 parts of glycol ether,

[0022] The composition of the waterproof topcoat in parts by mass is: 40 parts of polyether polyol, 30 parts of isocyanate, 25 parts of titanium dioxide, 11 parts of trimethylchlorosilane, 3 parts of fatty alcohol polyoxyethylene ether, polysiloxane 2 parts of leveling agent, 40 parts of No. 120 solvent naphtha.

[0023] The preparation method of the protective primer is as follows: mix alkyd resin, aluminum powder slurry, china clay, silicon dioxide and talc powder evenly, put them into a three-roll machine and grind them to a fineness of ≤45 μm, and then dissolve them in xyl...

Embodiment 2

[0027] A waterproof and oxidation-resistant insulating varnish for electric equipment, comprising a protective primer and a waterproof topcoat, the ingredients of the protective primer are: 40 parts by mass of xylene, 35 parts of alkyd resin, 15 parts of aluminum powder slurry, china clay 15 parts, 8 parts of talcum powder, 3 parts of dibutyltin dilaurate, 2 parts of silicon dioxide, 25 parts of glycol ether,

[0028] The composition of the waterproof topcoat in parts by mass is: 55 parts of polyether polyol, 40 parts of isocyanate, 30 parts of titanium dioxide, 15 parts of trimethylchlorosilane, 4 parts of fatty alcohol polyoxyethylene ether, polysiloxane 3 parts of leveling agent, 50 parts of No. 120 solvent naphtha.

[0029] The preparation method of the protective primer is as follows: mix alkyd resin, aluminum powder slurry, china clay, silicon dioxide and talc powder evenly, put them into a three-roll machine and grind them to a fineness of ≤45 μm, and then dissolve them...

Embodiment 3

[0033] A waterproof and oxidation-resistant insulating varnish for electric equipment, comprising a protective primer and a waterproof topcoat, the ingredients of the protective primer are: 35 parts by mass of xylene, 33 parts of alkyd resin, 12 parts of aluminum powder slurry, china clay 14 parts, 5 parts of talcum powder, 2 parts of dibutyltin dilaurate, 1 part of silicon dioxide, 20 parts of glycol ether,

[0034] The composition of the waterproof topcoat in parts by mass is: 50 parts of polyether polyol, 35 parts of isocyanate, 27 parts of titanium dioxide, 13 parts of trimethylchlorosilane, 3 parts of fatty alcohol polyoxyethylene ether, polysiloxane 2 parts of leveling agent, 45 parts of No. 120 solvent naphtha.

[0035] The preparation method of the protective primer is as follows: mix alkyd resin, aluminum powder slurry, china clay, silicon dioxide and talc powder evenly, put them into a three-roll machine and grind them to a fineness of ≤45 μm, and then dissolve them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com