High-temperature-resistant coating with electromagnetic shielding performance and preparation method thereof

A high-temperature-resistant coating and electromagnetic shielding technology, applied in conductive coatings, fire-resistant coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor heat resistance and poor electromagnetic shielding effect, and achieve smooth surface, easy movement, and good peelability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

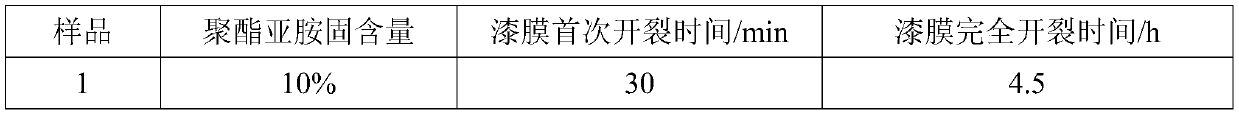

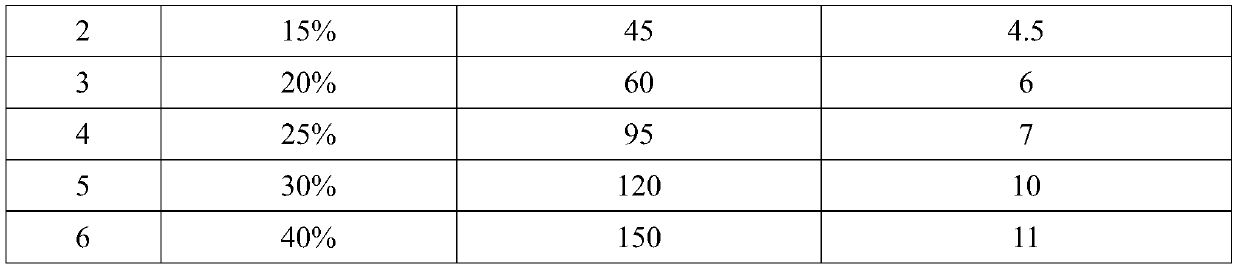

Examples

Embodiment 1

[0035] A preparation method of a high temperature resistant coating with electromagnetic shielding performance, the specific steps are as follows:

[0036](1) Preparation of polyesterimide resin

[0037] a. Take 110 parts of cresol and add it into the reactor, control the stirring speed to 2500~5000r / min, raise the temperature to 60°C under stirring, add 29.1 parts of trimellitic anhydride and 15.1 parts of 4,4'-diaminodiphenylmethane, slowly Raise the temperature to 120°C and keep it for 30 minutes; then raise the temperature to 145°C and keep it for 3 hours; finally cool down to 130°C;

[0038] b. Control the stirring speed at 3000-6000r / min, add 19.6 parts of dimethyl terephthalate, 28.2 parts of tris(2-hydroxyethyl)isocyanurate, 5.5 parts of ethylene glycol and The cresol solution of n-butyl titanate (0.2 parts of n-butyl titanate, 1 part of cresol), the temperature was raised to 150°C, and kept stirring for 2h; The reaction temperature was reacted at 190° C. until the r...

Embodiment 2

[0045] A preparation method of a high temperature resistant coating with electromagnetic shielding performance, the specific steps are as follows:

[0046] (1) Preparation of polyesterimide resin

[0047] a. Take 110 parts of cresol and add it into the reactor, control the stirring speed to 2500~5000r / min, raise the temperature to 60°C under stirring, add 29.1 parts of trimellitic anhydride and 15.1 parts of 4,4'-diaminodiphenylmethane, slowly Raise the temperature to 120°C and keep it for 30 minutes; then raise the temperature to 145°C and keep it for 3 hours; finally cool down to 130°C;

[0048] b. Control the stirring speed at 3000-6000r / min, add 19.6 parts of dimethyl terephthalate, 28.2 parts of tris(2-hydroxyethyl)isocyanurate, 6 parts of ethylene glycol and The cresol solution of n-butyl titanate (0.2 parts of n-butyl titanate, 1.5 parts of cresol), raised the temperature to 150°C, kept stirring for 2 hours; The reaction temperature was reacted at 190° C. until the re...

Embodiment 3

[0055] A preparation method of a high temperature resistant coating with electromagnetic shielding performance, the specific steps are as follows:

[0056] (1) Preparation of polyesterimide resin

[0057] a. Take 110 parts of cresol and add it into the reactor, control the stirring speed to 2500~5000r / min, raise the temperature to 60°C under stirring, add 29.1 parts of trimellitic anhydride and 15.1 parts of 4,4'-diaminodiphenylmethane, slowly Raise the temperature to 120°C and keep it for 30 minutes; then raise the temperature to 145°C and keep it for 3 hours; finally cool down to 130°C;

[0058] b. Control the stirring speed at 3000-6000r / min, add 19.6 parts of dimethyl terephthalate, 28.2 parts of tris(2-hydroxyethyl)isocyanurate, 5.5 parts of ethylene glycol and The cresol solution of n-butyl titanate (0.2 parts of n-butyl titanate, 1 part of cresol), the temperature was raised to 150°C, and kept stirring for 2h; then the temperature was raised to 160°C, and kept for 1h; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com