Steel rail deflection adjusting device and long steel rail train set

An adjustment device and long rail technology, applied in the field of rail trains, can solve problems such as heavy weight, long rail length, and downward bending, and achieve the effects of convenient transportation, improved transportation efficiency, and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] The steel rail deflection adjusting device provided by the present invention is suitable for being installed on a train in operation of a long rail train set or a train with a similar structure. The steel rail deflection adjustment referred to in the present invention refers to the suppression of excessive downward bending of the long steel rail.

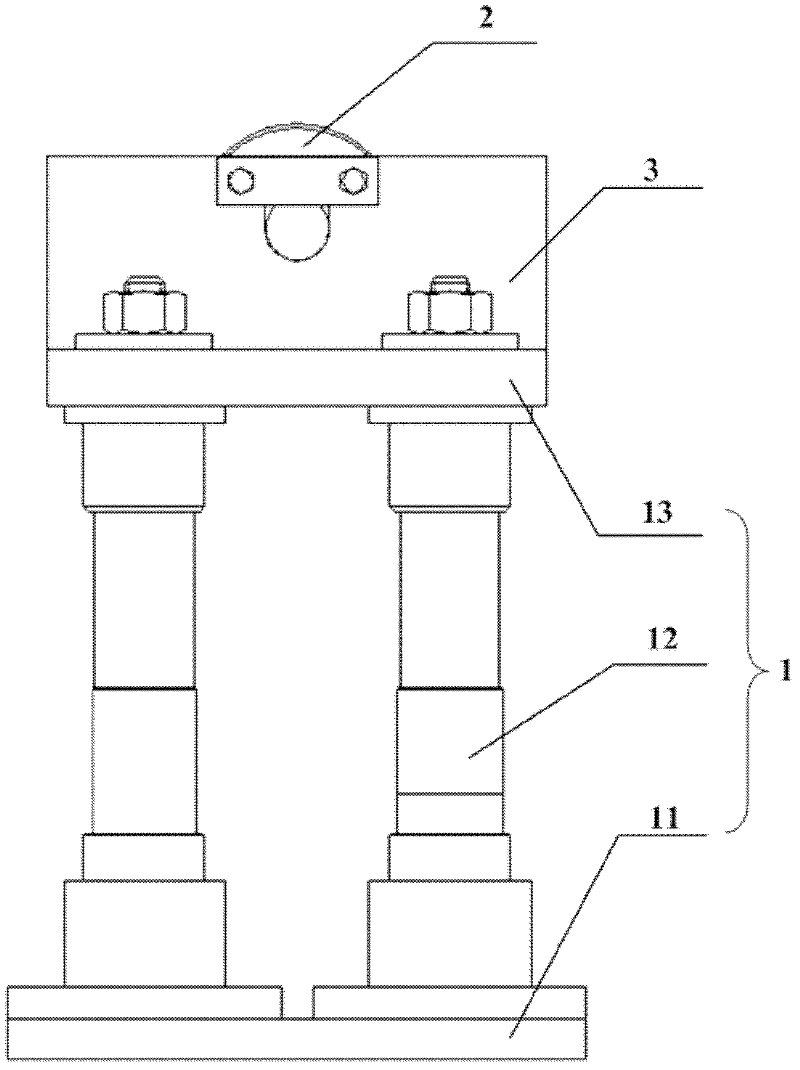

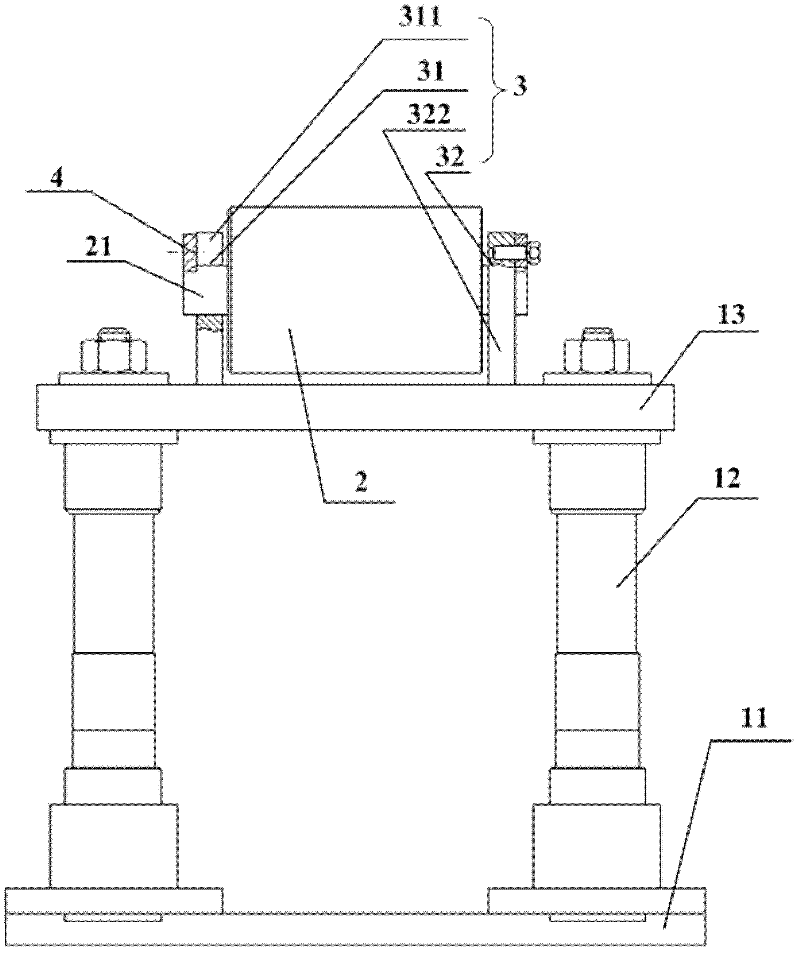

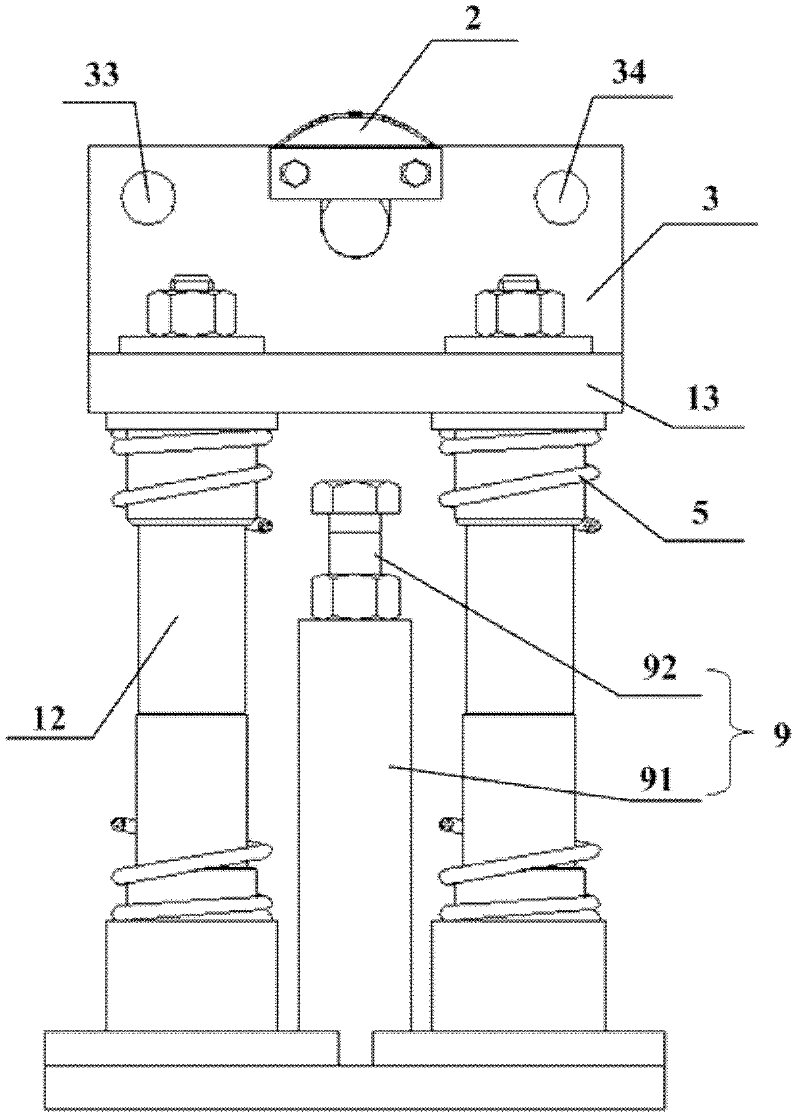

[0034] Figure 1a It is a schematic structural diagram of the first embodiment of the rail deflection adjusting device of the present invention, Figure 1b for Figure 1a Left view. See Figure 1a with Figure 1b The rail deflection adjustment device has a support table 1 on which a roller 2 is provided. The roller 2 is used to carry the long rail to be transported, and the roller resistance is small.

[0035] The rail deflection adjustment device is used to install between two sections of rail unloading guide grooves. The long rail slides along the unloading guide groove under the action of external force, and after pressing against...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap