Dynamic safety monitoring device of brake and monitoring method

A dynamic safety and monitoring device technology, applied in safety devices, transportation and packaging, load suspension components, etc., can solve problems such as insufficient safety of lifting mechanism, insufficient judgment of brake safety, and discrepancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

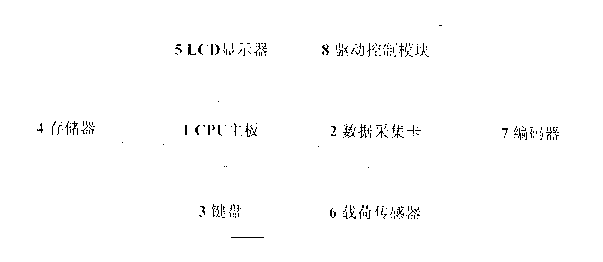

[0054] see figure 1 , The invention provides a brake dynamic safety monitoring device, which is mainly composed of a CPU main board 1, an acquisition card 2, a load sensor 6, an encoder 7, a drive control module 8, a keyboard 3, a memory 4 and an LCD display 5.

[0055] The CPU motherboard 1, the load sensor 6, the encoder 7 and the drive control module 8 are respectively connected to the acquisition card 2. The acquisition card 2 collects the signals of the load sensor 6 and the encoder 7 in real time through the analog input interface, and the CPU mainboard 1 reads the data of the relevant channels in the acquisition card 2 and calculates information such as the current load value, braking speed, and braking displacement.

[0056] The keyboard 3, the memory 4 and the LCD display 5 are respectively connected to the CPU main board 1, and the keyboard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com