Grade variable compressor

A compressor and cylinder technology, which is applied in the field of variable-stage compressors, can solve the problems of exceeding the energy efficiency range and high power, and achieve the effect of improving the heating capacity and improving the high-temperature cooling capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

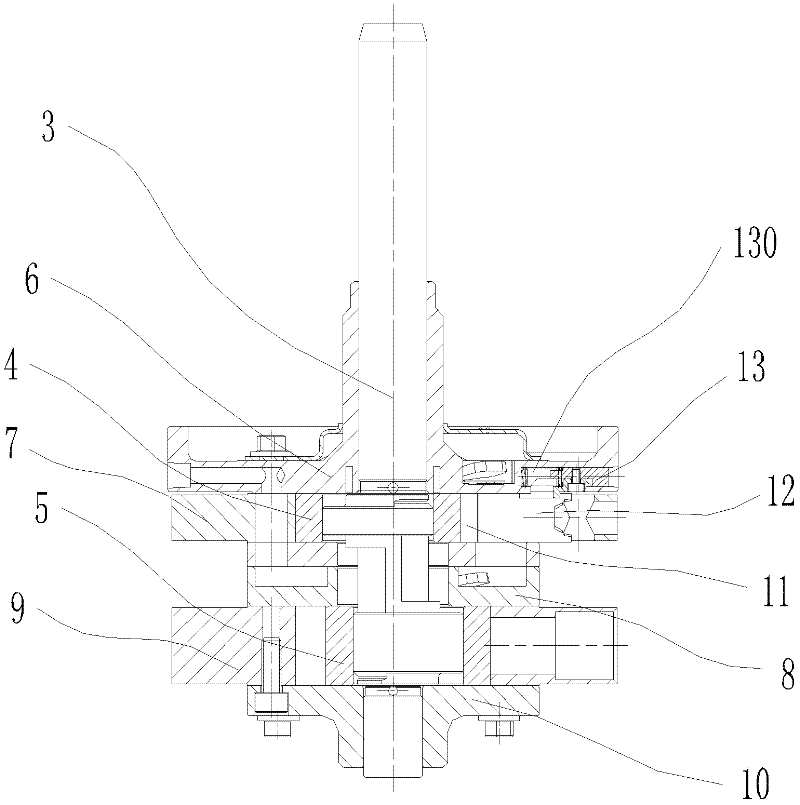

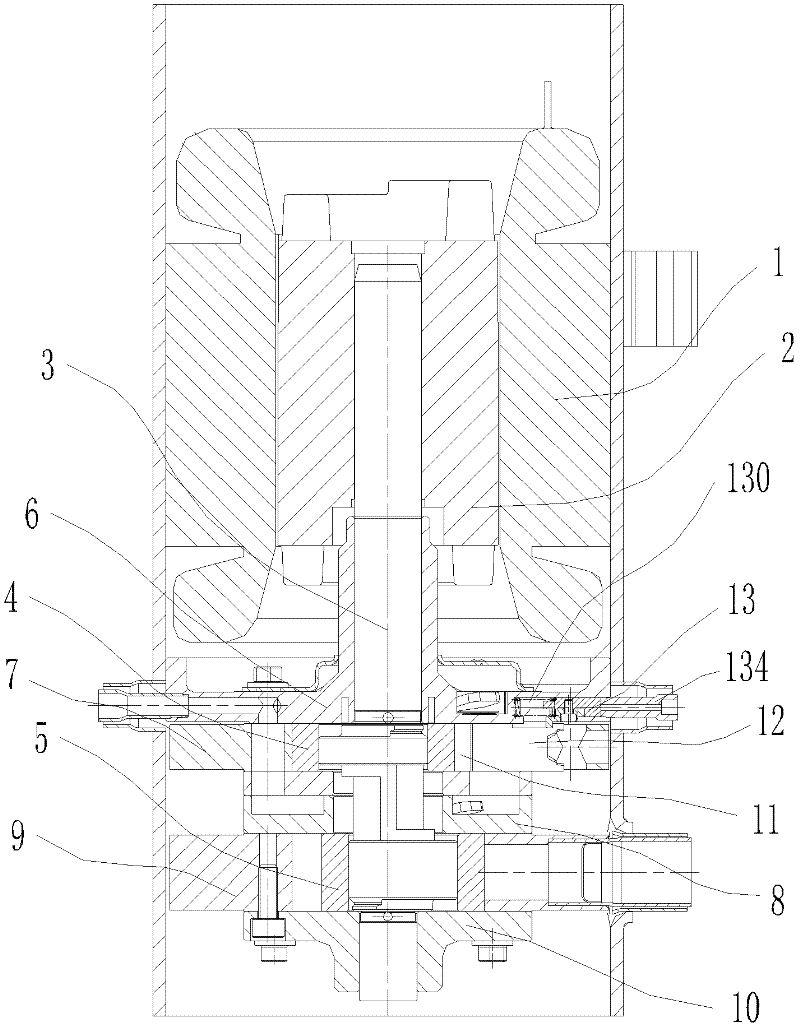

[0016] Such as Figure 1 to Figure 6 As shown, a variable-stage compressor includes a motor stator 1, a rotor 2, a crankshaft 3, an upper roller 4, a lower roller 5, an upper flange 6, an upper cylinder 7, a partition 8, a lower cylinder 9 and a lower method Lan 10, the upper and lower rollers (4, 5) are respectively installed on the crankshaft 3 and rotate in the cavity of the upper and lower cylinders (7, 9) to work, the cylinder wall of the upper cylinder 7 is provided with a slide groove 11, and the slide The groove 11 is equipped with an upper slide 12 that cooperates with the upper roller 4; the upper flange 6 is equipped with a slide control device 13 that controls the action of the upper slide 12 so that the upper cylinder 7 of the compressor can selectively participate in the compression work.

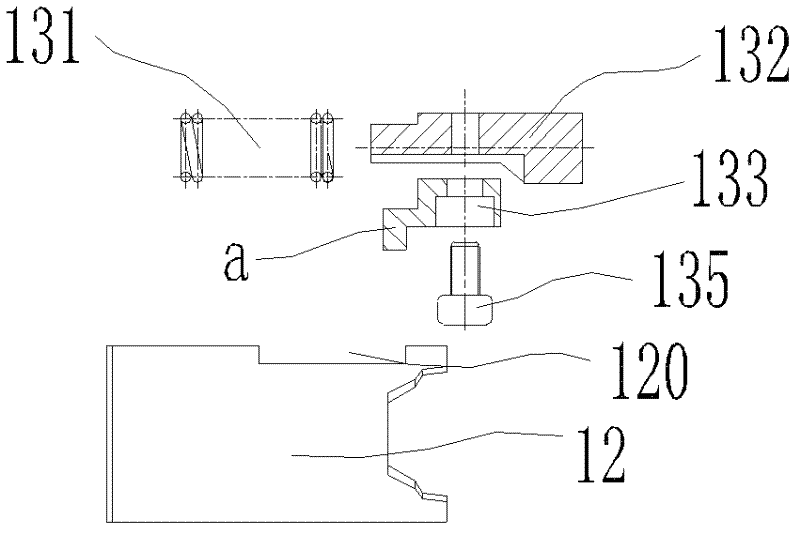

[0017] continue as Figure 1 to Figure 6 As shown, the sliding vane control device 13 includes a plunger hole 130 set in the radial direction of the upper flange 6, a spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com