Printing head

A printing head and anti-disassembly technology, which is applied in the field of printing head, can solve the problems such as difficult to judge the dismantling of the printing head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The print head provided by the embodiments of the present invention will be further described in detail below with reference to specific embodiments and drawings.

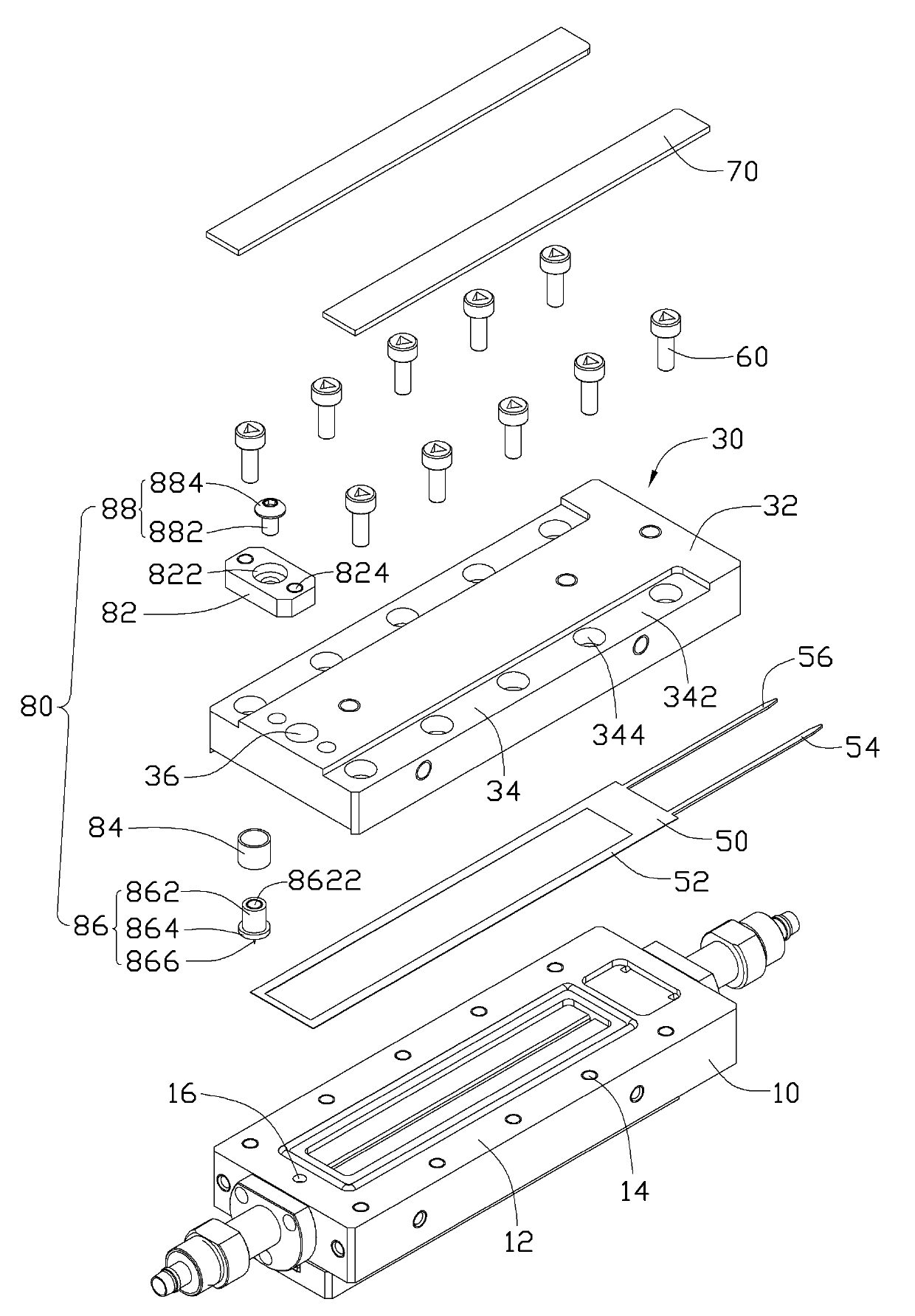

[0048] see figure 1 and figure 2 , the print head 100 according to the first embodiment of the present invention includes a nozzle body 10 , a pressure plate 30 , an oscillating plate 50 , a connecting piece 60 , a shroud 70 and an anti-tampering component 80 . The oscillating plate 50 is clamped between the nozzle body 10 and the pressure plate 30 , and the pressure plate 30 is fixed to the nozzle body 10 through the connecting piece 60 . The shield 70 is fixed to the platen 30 and shields the connector 60 . The anti-tampering component 80 is disposed on the pressing plate 30 .

[0049] Please also see figure 2 and image 3 , the nozzle body 10 is substantially rectangular and has a resisting surface 12 . A plurality of connection holes 14 are defined on the resisting surface 12 . A plurality of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com