Method for catalyzing cycloalkane by utilizing Sn-containing Ti-Si molecular sieve

A molecular sieve catalyzed oxidation of naphthenes and cycloalkanes, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, and the preparation of oxygenated compounds by oxidation of hydrocarbons, can solve the problems of difficult purification, short service life, difficult recovery, etc., and achieve the goal of overcoming the production process complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0040] This example illustrates the synthesis process of TS-1 molecular sieve and the synthesis process of tin-containing titanium silicon molecular sieve according to the method of Zeolites, 1992, Vol.12, pages 943-950.

[0041] Mix 22.5 grams of tetraethyl orthosilicate with 7.0 grams of tetrapropylammonium hydroxide, add 59.8 grams of distilled water, mix well, and then hydrolyze at normal pressure and 60°C for 1.0 hour to obtain a hydrolysis solution of tetraethyl orthosilicate A solution consisting of 1.1 g of tetrabutyl titanate and 5.0 g of anhydrous isopropanol was slowly added under vigorous stirring, and the resulting mixture was stirred at 75° C. for 3 hours until it became a clear and transparent colloid. Put the colloid into a stainless steel sealed reaction kettle, and place it at a constant temperature of 170°C and autogenous pressure for 6 days to obtain a mixture of crystallized products; filter the mixture, wash it with water until the pH is 6-8, and dry it at...

preparation Embodiment 2

[0043] Take the TS-1 molecular sieve obtained in Catalyst Preparation Example 1 according to the ratio of molecular sieve (g): sulfuric acid (mol): water (mol) = 100: 0.15: 15 and mix evenly, react at 90 ° C for 5.0 hours, and then follow the conventional method Filtration, washing and drying yielded acid-treated TS-1 molecular sieves.

[0044] The above-mentioned acid-treated TS-1 molecular sieves were mixed uniformly according to the ratio of molecular sieve (gram): triethanolamine (mol): tetrapropylammonium hydroxide (mol): water (mol) = 100: 0.20: 0.15: 180, and put into A stainless steel sealed reaction kettle was placed at a constant temperature of 190°C and autogenous pressure for 0.5 days. After cooling and pressure relief, it was filtered, washed, dried according to conventional methods, and roasted in an air atmosphere at 550°C for 3 hours to obtain a hollow structure molecular sieve.

[0045] According to X-ray diffraction analysis, it is a titanium-silicon molecula...

Embodiment 1

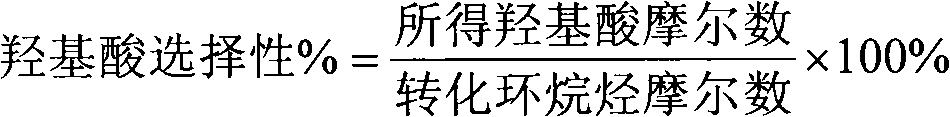

[0048]Weigh 2.3 grams of tin-containing titanium-silicon molecular sieve Sn-TS-1 (the mass percent of Sn is 1.2wt%, in terms of oxides, the same below) catalyst is loaded in a 100ml three-necked flask, then add a magnetic stirrer, 4.21 grams Cyclopentane, 3.6 grams of water and 23ml of 30% hydrogen peroxide, the molar ratio of cyclopentane to hydrogen peroxide is 1:4. The three-necked flask is placed on a temperature-controlled magnetic stirrer, and the upper part of the three-necked flask is condensed and refluxed with a condenser, and the magnetic stirrer and heating device are started to start the reaction. The reaction temperature is controlled at about 80° C., and after 6 hours of reaction, the conversion rate of cyclopentane is 20.65%, and the selectivity of forming the corresponding δ-lactone is 26.79%. The selectivity for 5-hydroxypentanoic acid was 35.17%, and the selectivity for glutaric acid was 33.23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com