Method of catalytic oxidization of cyclic ketone by using tin supported molecular sieve

A technology of catalytic oxidation and all-silicon molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems that do not conform to the basic principles of green chemistry, the properties of heteropolyacid catalysts are unstable, and purification is difficult. , achieve catalytic oxidation activity and catalytic activity stability, high catalytic oxidation activity and activity stability, and overcome the complex production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

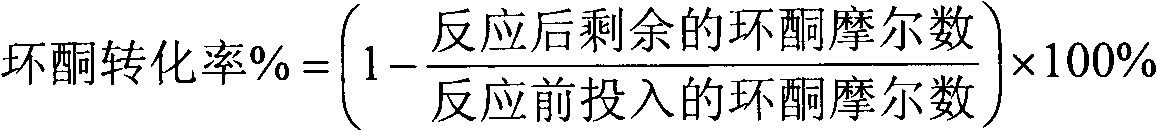

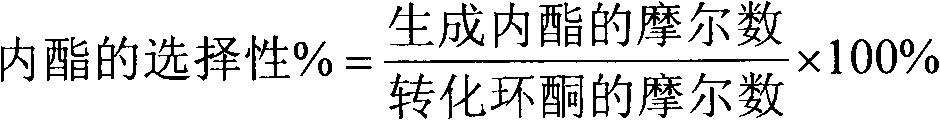

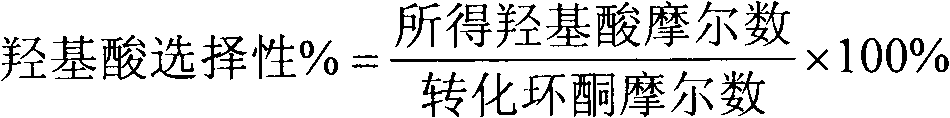

Embodiment 1

[0042] Weigh 2.3 grams of tin-loaded all-silicon molecular sieve SnO 2 / S-1(SnO 2 The massfraction is 2.3wt%) catalyzer is contained in the 100ml three-necked flask, then add magnetic stirrer, 19.63 gram cyclohexanone, 3.6 gram water and 46ml concentration successively and be 30% hydrogen peroxide, now cyclohexanone and peroxide The molar ratio of hydrogen is 1:2. The three-necked flask is placed on a temperature-controlled magnetic stirrer, and the upper part of the three-necked flask is condensed and refluxed with a condenser, and the magnetic stirrer and heating device are started to start the reaction. The reaction temperature was controlled at about 80°C. After 8 hours of reaction, the conversion rate of cyclohexanone was 40.65%, the selectivity of generating ε-caprolactone was 26.45%, the selectivity of 6-hydroxycaproic acid was 31.68%, and the Acid selectivity was 24.12%.

Embodiment 2

[0044] Weigh 2.44 grams of tin-loaded all-silicon molecular sieve SnO 2 / S-1 catalyst (SnO 2 The mass fraction is 1.9wt%) is installed in the 100ml three-neck flask, then add magnetic stirrer, 19.63 grams of cyclohexanone, 23 grams of acetone and 23ml concentration successively and be 30% hydrogen peroxide, now cyclohexanone and hydrogen peroxide The molar ratio is 1:1. The three-necked flask is placed on a temperature-controlled magnetic stirrer, and the upper part of the three-necked flask is condensed and refluxed with a condenser, and the magnetic stirrer and heating device are started to start the reaction. The reaction temperature was controlled at about 60°C. After 3 hours of reaction, the conversion rate of cyclohexanone was 37.82%, the selectivity of ε-caprolactone was 89.45%, the selectivity of 6-hydroxycaproic acid was 3.29%, and the selectivity of adipic acid was 37.82%. The selectivity is 0.41%.

Embodiment 3

[0046] Weigh 2.65 grams of tin-loaded all-silicon molecular sieve SnO 2 / S-1 catalyst (SnO 2 The mass fraction is 3.3wt%) to be installed in the 100ml three-necked flask, then add magnetic stirrer, 19.63 gram cyclohexanone, 18 gram dioxane and 46ml concentration successively and be 30% hydrogen peroxide, now cyclohexanone and The molar ratio of hydrogen peroxide is 1:2. The three-necked flask is placed on a temperature-controlled magnetic stirrer, and the upper part of the three-necked flask is condensed and refluxed with a condenser, and the magnetic stirrer and heating device are started to start the reaction. The reaction temperature was controlled at about 93°C. After 6 hours of reaction, the conversion rate of cyclohexanone was 89.57%, the selectivity of ε-caprolactone was 95.45%, the selectivity of 6-hydroxycaproic acid was 2.37%, and the selectivity of adipic acid The selectivity is 1.18%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com