Etching method and system

An etching system and main etching technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as large CD, metal layer etching residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

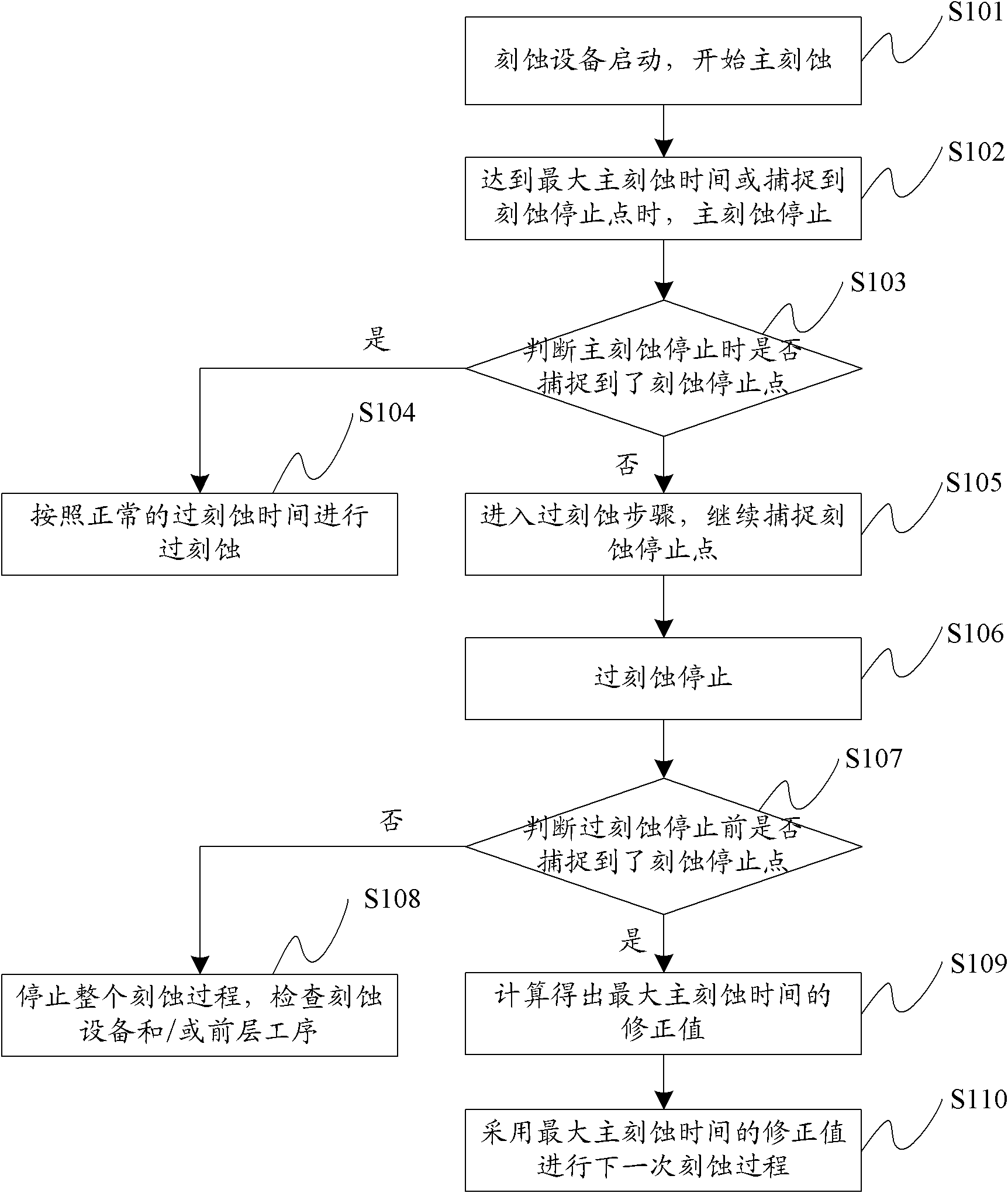

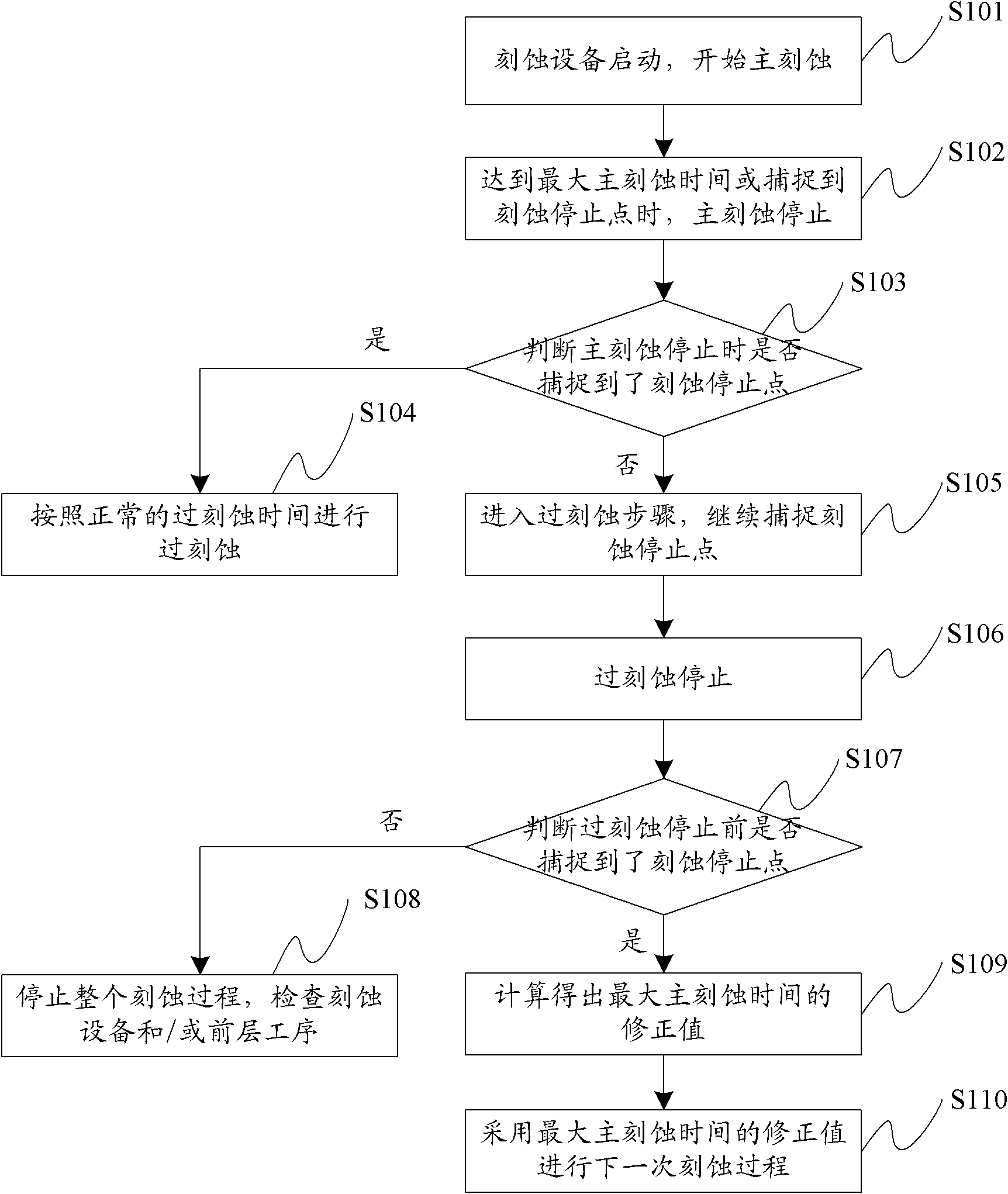

[0045] Based on this, the first embodiment provides an etching method. The flowchart of the method is as follows: figure 1 As shown, including the following steps:

[0046] Step S101: the etching equipment is started to start the main etching;

[0047] Step S102: When the maximum main etching time is reached or the etching stop point is captured, the main etching stops;

[0048] Step S103: After the main etching is stopped, determine whether the etching stop point is captured when the main etching is stopped, if yes, go to step S104, if not, go to step S105;

[0049] It should be noted that the determination step is added in this embodiment to determine whether the maximum main etching time set initially is sufficient to capture the etching stop point, and to lay a foundation for whether the maximum main etching time needs to be extended in the future.

[0050] Step S104: If the main etching stops at the etching stop point, it means that the set maximum main etching time is sufficient t...

Embodiment 2

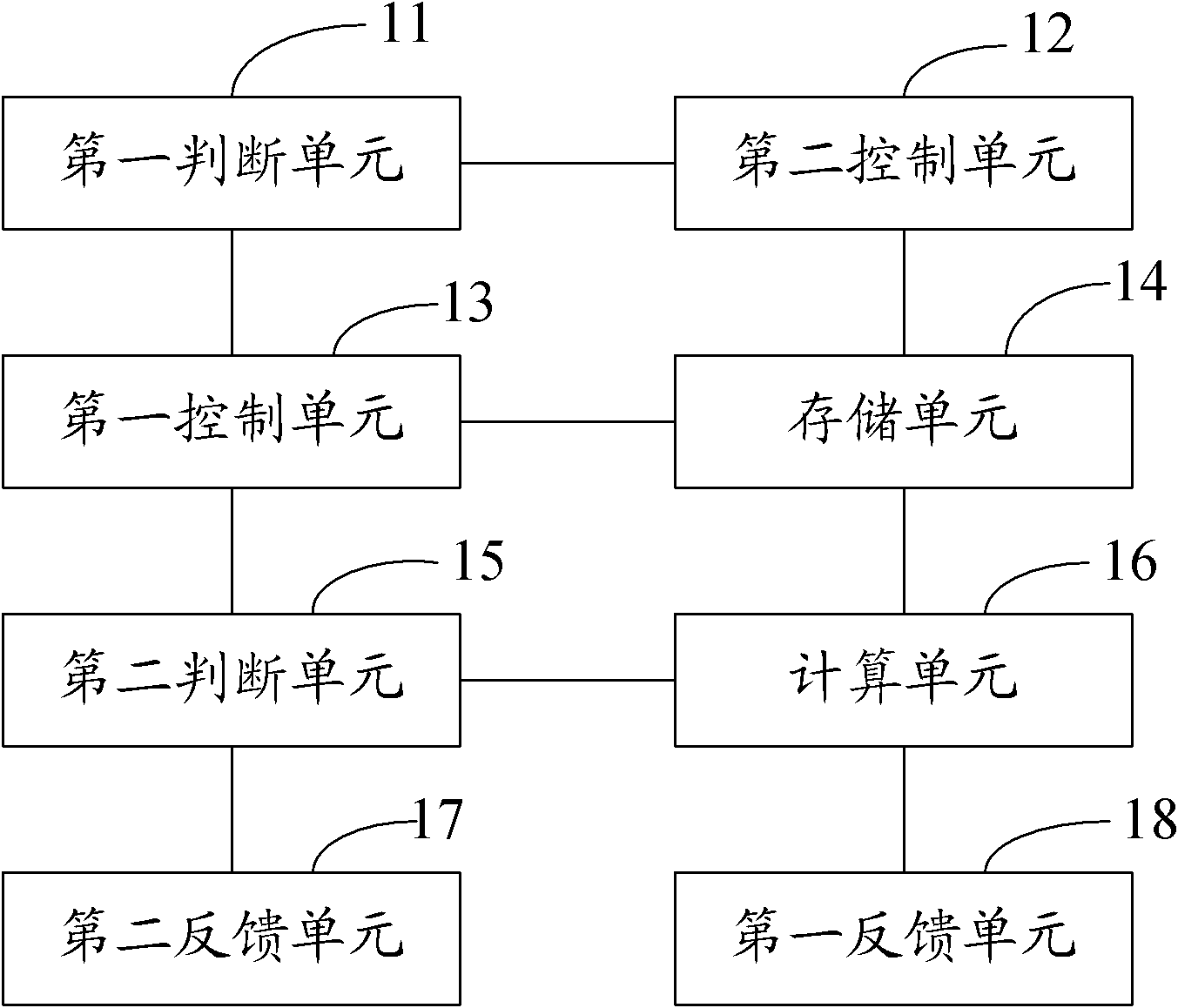

[0075] Corresponding to the method embodiment, this embodiment discloses an etching system. The structure diagram of the system is as follows: figure 2 As shown, the system includes:

[0076] The first judging unit 11 is used for judging whether an etching stop point is captured when the main etching is stopped after the main etching is stopped;

[0077] The first control unit 13 is used to control the etching equipment to enter the over-etching and continue to capture the etching stop point under the condition that the etching stop point is not captured when the main etching is stopped. It stops automatically when the maximum over-etching time is set, and after capturing the stop point of etching, it stops automatically when the normal over-etching time passes;

[0078] The second judging unit 15 is used to judge whether an etching stop point is captured before the over-etching is stopped after the over-etching is stopped;

[0079] The calculation unit 16 is used to obtain the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com