Fiber ink-jet printing equipment

A fiber and fiber completion technology, which is used in the field of inkjet printers to print patterns or patterns on the surface of fibers, can solve problems such as being unable to grasp the development direction of wide-format inkjet printing control technology, affecting the performance and life of equipment and components

Inactive Publication Date: 2012-06-13

JIANGNAN UNIV

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the fierce competition in this industry, such profits will become lower and lower. Moreover, the compatibility and stability problems brought about by the assembled production of components also affect the service performance and lifespan of equipment and components; at the same time, due to the lack of Or do not have the ability to invest in research and development of wide-format printing equipment and printing technology, and most manufacturers cannot grasp the future development direction of wide-format printing control technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

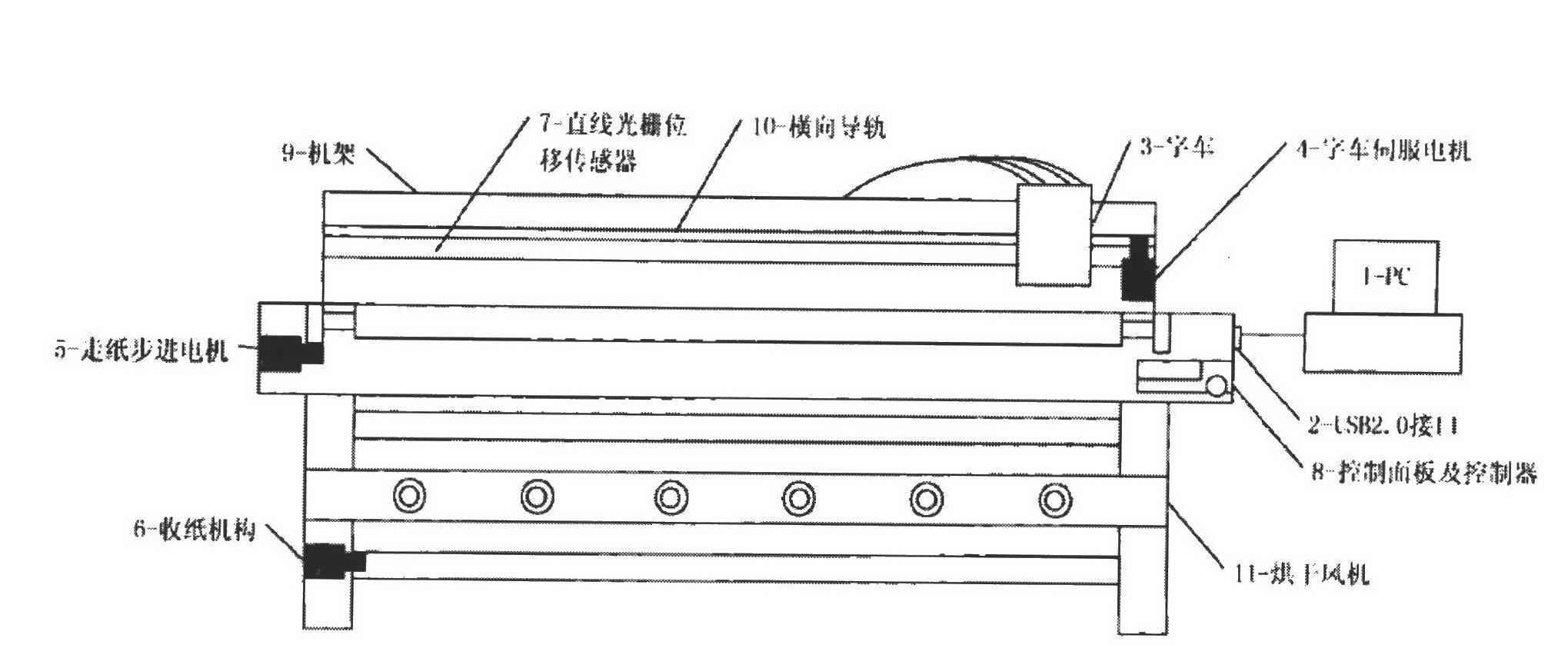

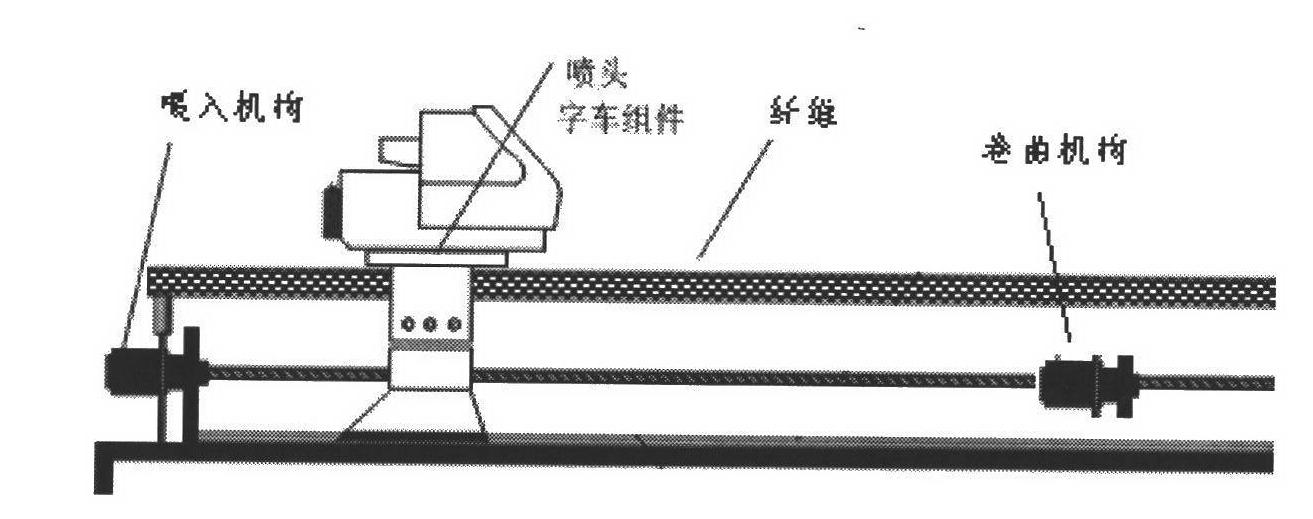

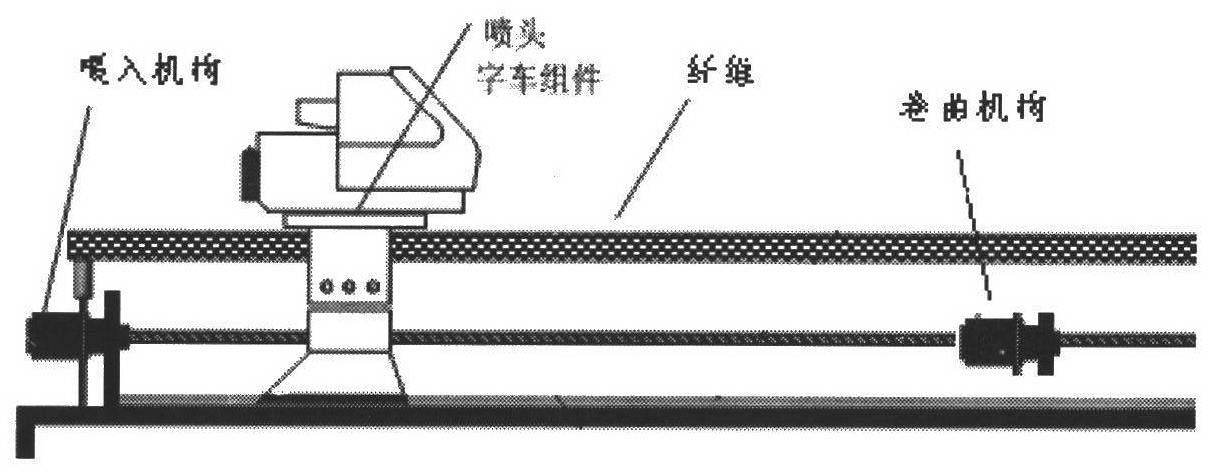

[0018] The controller of the whole fiber inkjet printing equipment is mainly composed of the feeding mechanism and the print head car assembly, and the block diagram is as follows: figure 2 shown. The fibers are spread on the surface of the belt, and with the movement of the belt, the printer prints corresponding patterns on the surface of the fibers.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Aiming at the current domestic ink-jet printer, the invention provides fiber ink-jet printing equipment. For the fiber ink-jet printing equipment, a winding mechanism is utilized for realizing continuous feeding and take-up of fiber, so that an image set by a computer can be conveniently printed on the surface of the fiber, and finally the surface of the fiber is ensured to have different patterns. The invention provides the novel mechanism, so that a new function is provided for the ink-jet printer.

Description

technical field [0001] The present invention relates to a method of printing a pattern or pattern onto the surface of fibers using an inkjet printer. It uses a winding mechanism to continuously feed and take up the fiber, so that the image set by the computer can be printed on the surface of the fiber, so that the surface of the final fiber has different patterns, adding a new kind of inkjet printer. the use of. Background technique [0002] my country's wide-format inkjet printing market is booming, and the use of large-format color inkjet printing products is becoming more and more widespread. In outdoor media, such as various buildings, road signs, light box advertisements, decoration and photography, and textile printing and dyeing industries have matured and widely used. The application of this has also brought about the rapid development of my country's wide-format printing equipment industry. Compared with traditional printing machines and dot matrix printers, large-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B41J29/393B41J3/407

Inventor 刘基宏赵晓曼

Owner JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com