Patents

Literature

64results about How to "Real-time fully automatic control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent spun-yarn fineness random disturbance control device

InactiveCN102517716AReal-time fully automatic controlEfficient fully automatic controlTextiles and paperFinenessYarn

An intelligent spun-yarn fineness random disturbance control device belongs to the field of novel textile machinery. The fineness of spun yarns changes in any time in production of the spun yarns, roller rotation speed can be adjusted to control evenness of the spun yarns, and a distance between a detection point and a point of roller rotation speed adjustment is very short, so that a high-speed real-time processing device is required. FPGA (field programmable gate array) serves as a system control core for processing fluctuation information of spun-yarn fineness signals, and the signals are used as signals for controlling rotation speed of a motor of a spinning frame later. The intelligent spun-yarn fineness random disturbance control device is also applicable to cotton carding, drawing and roving procedures in textile production.

Owner:JIANGNAN UNIV

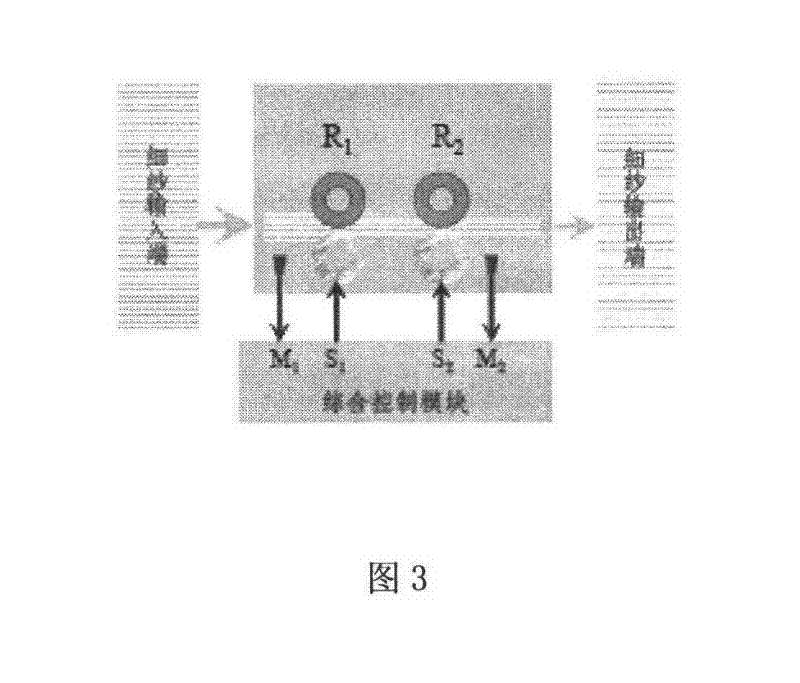

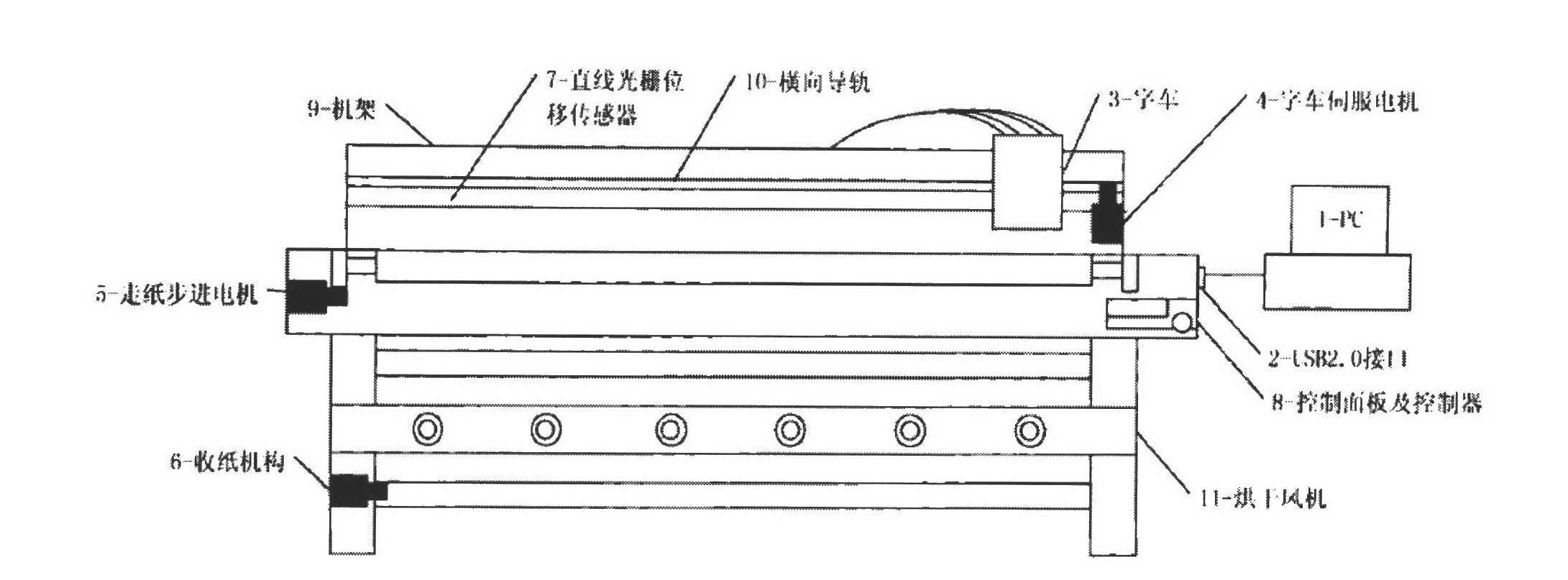

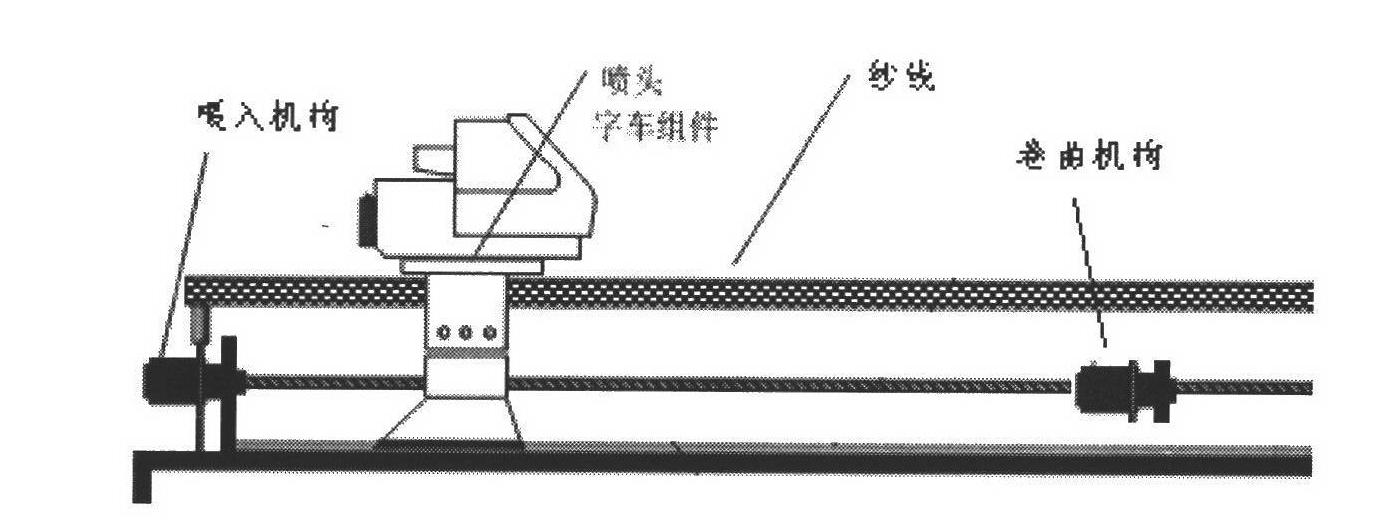

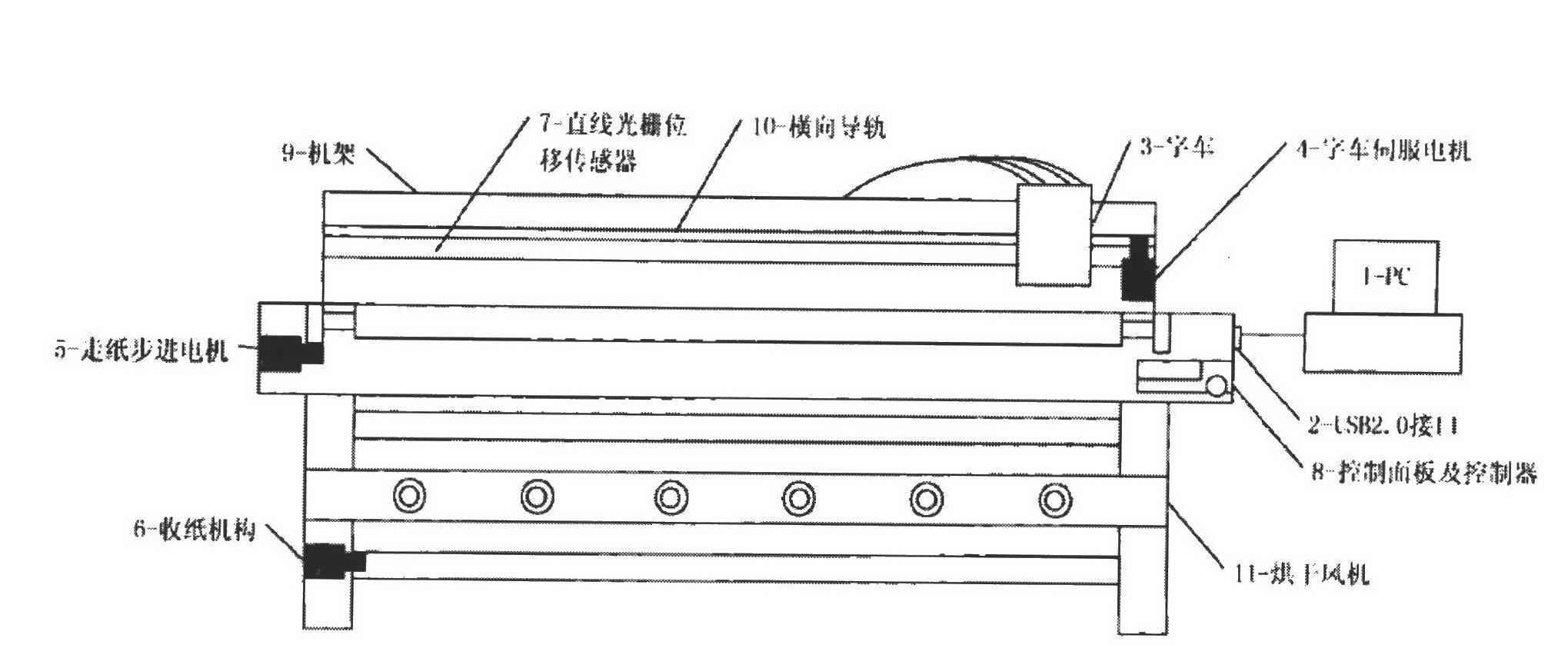

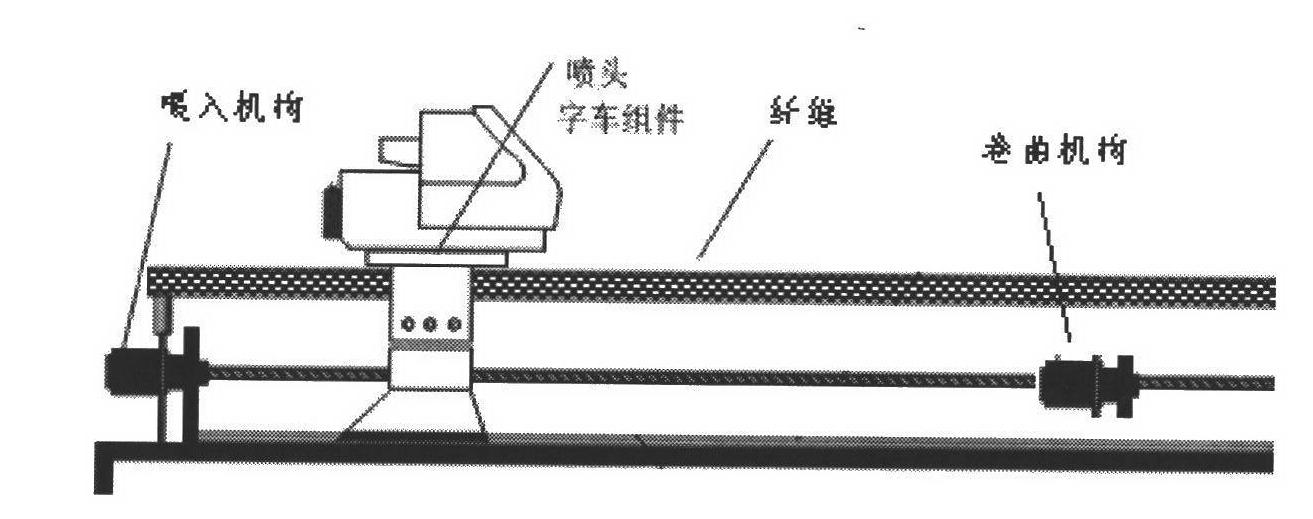

Yarn printing and conveying mechanism for ink-jet printing machine

InactiveCN102555535AReal-time fully automatic controlTypewritersOther printing apparatusYarnComputer engineering

Aiming at the existing domestic ink-jet printing machine, a yarn is continuously fed and wound by a winding mechanism to print an image set by a computer to the surface of the yarn, so that different patterns are formed on the surface of the final yarn. The invention provides a new mechanism so as to add a new purpose for an ink-jet printing machine.

Owner:JIANGNAN UNIV

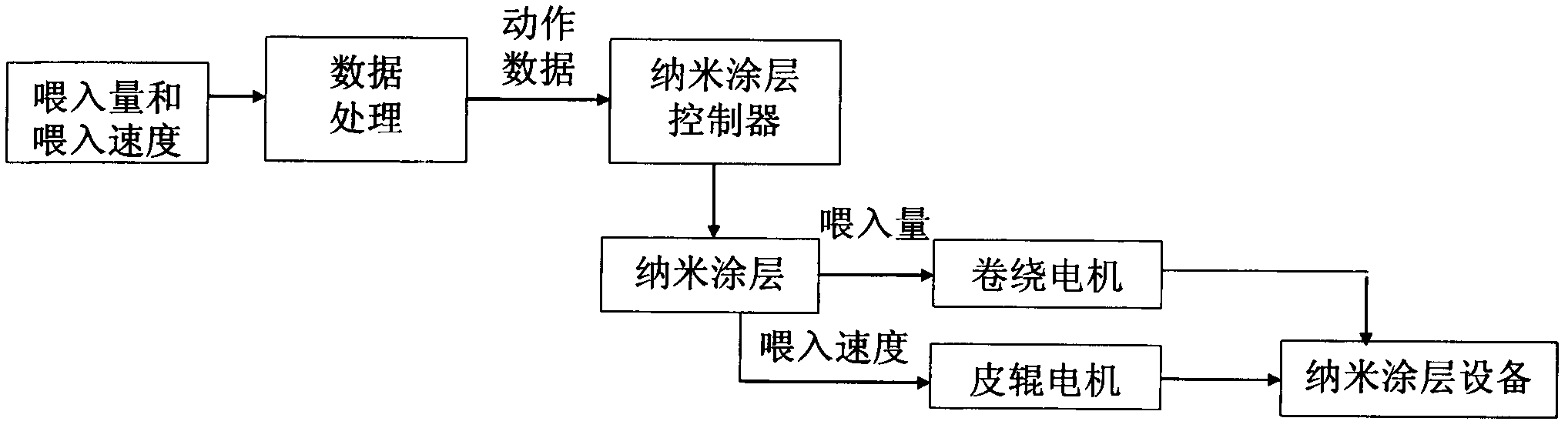

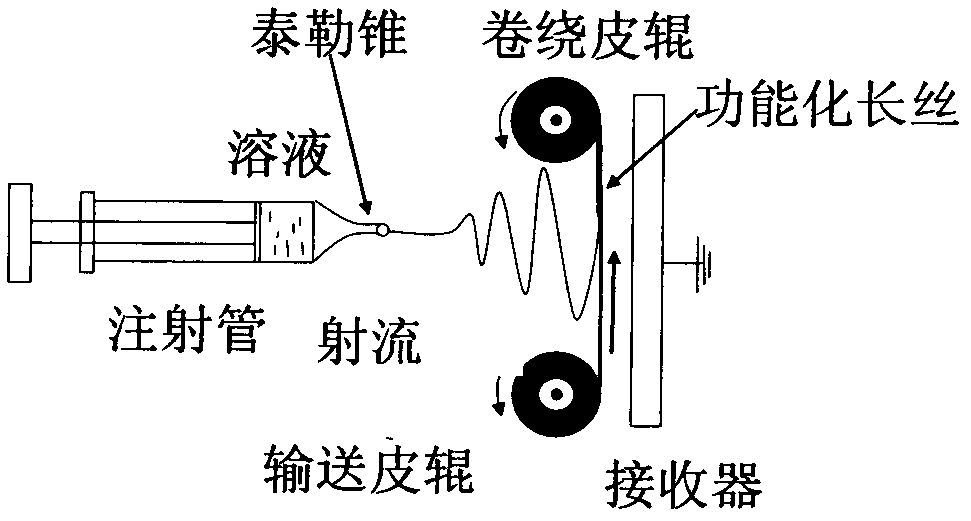

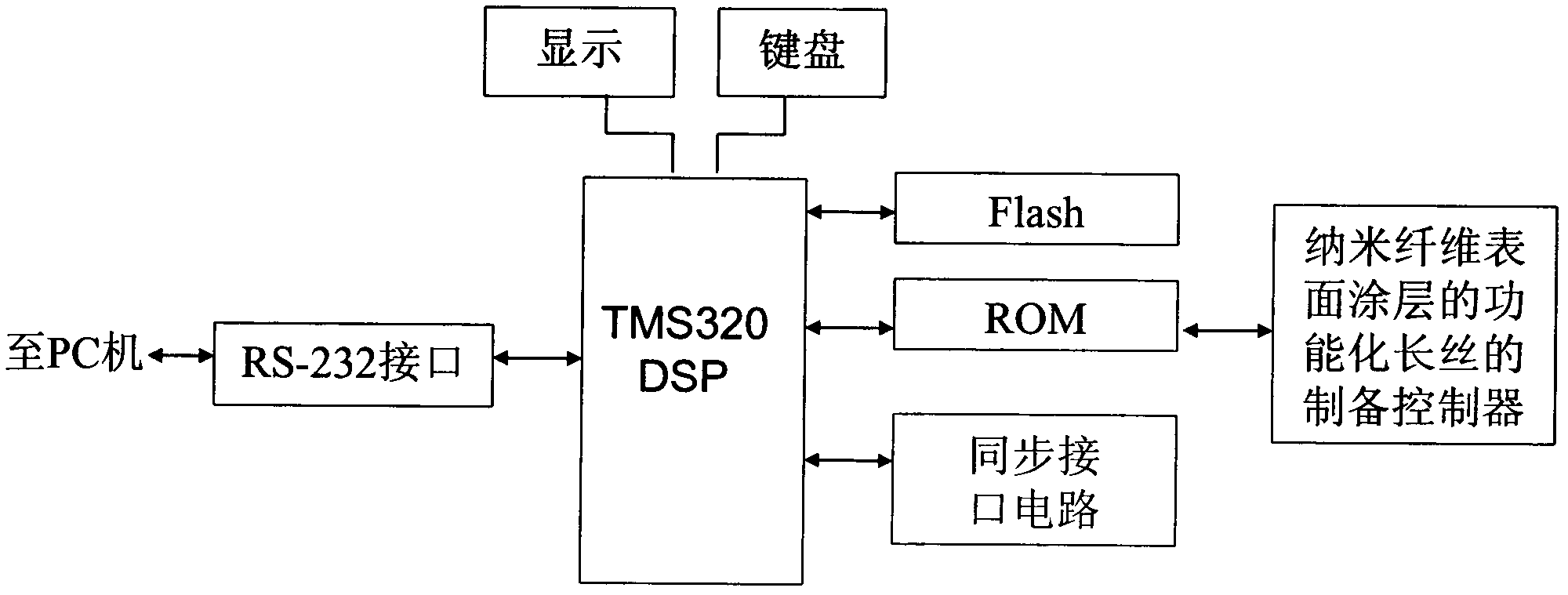

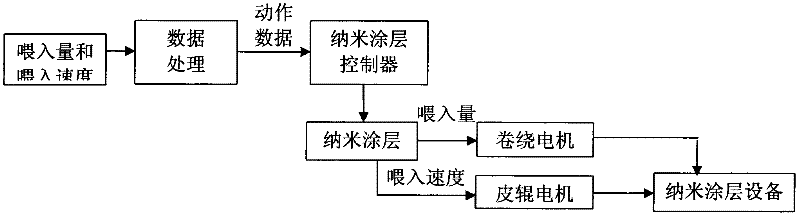

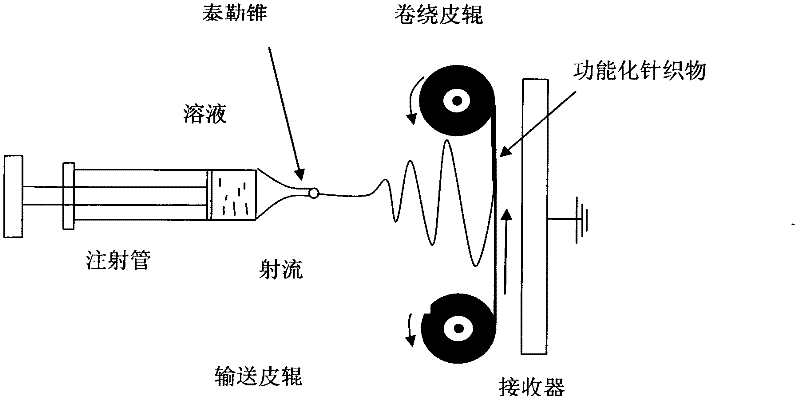

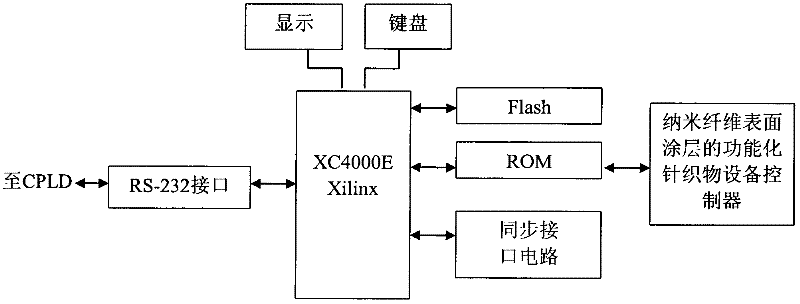

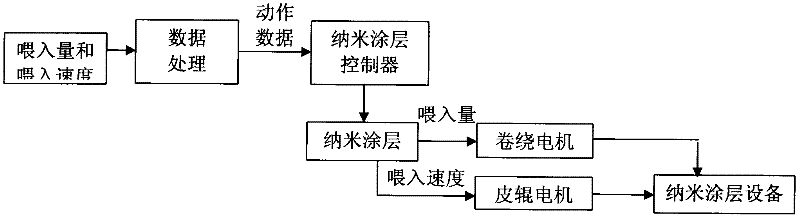

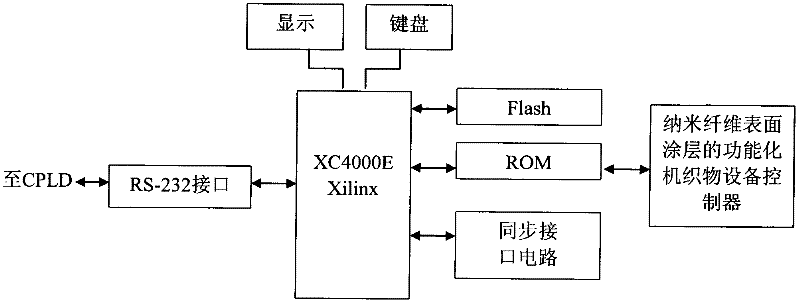

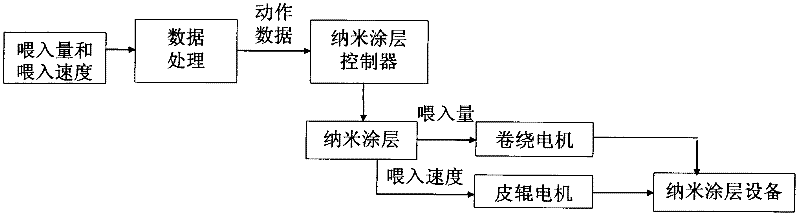

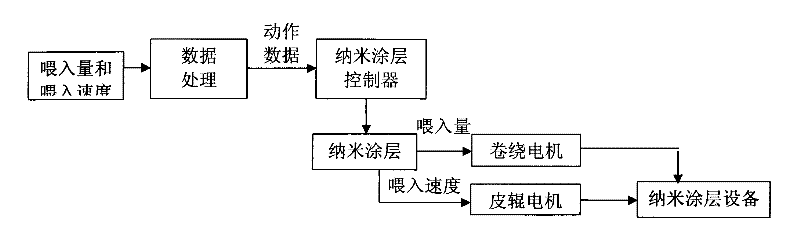

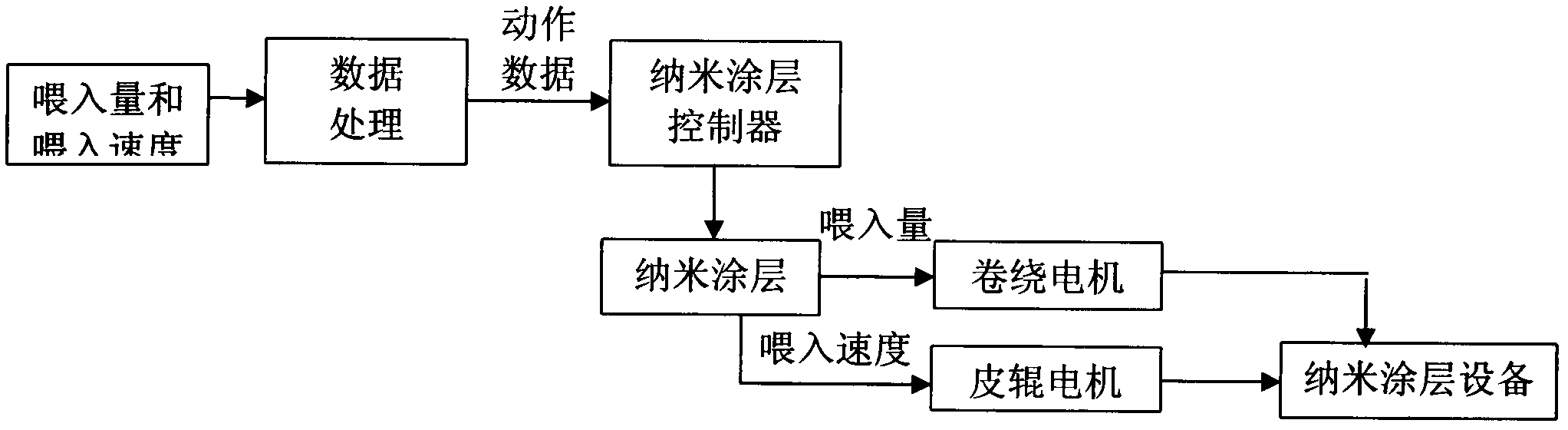

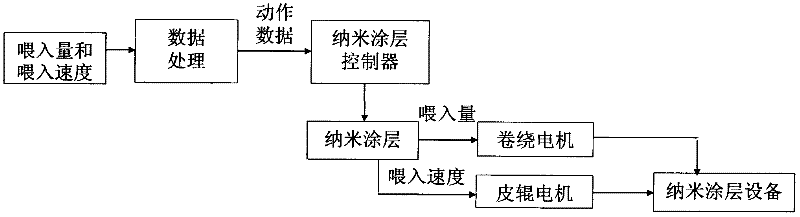

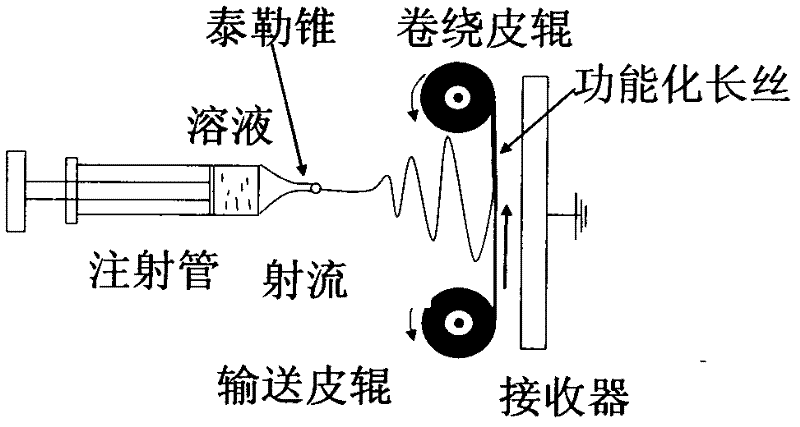

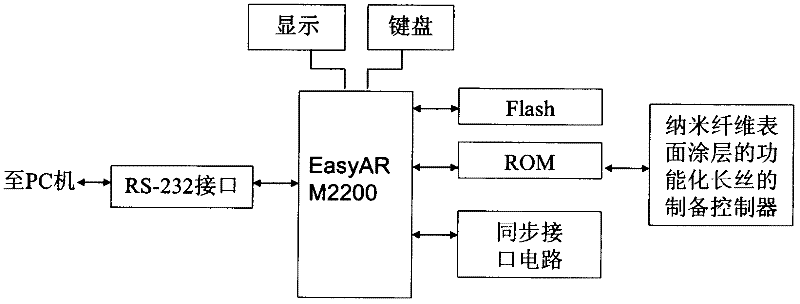

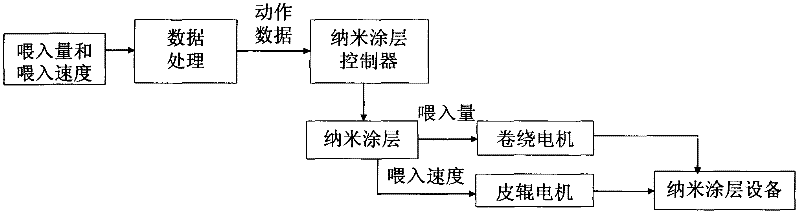

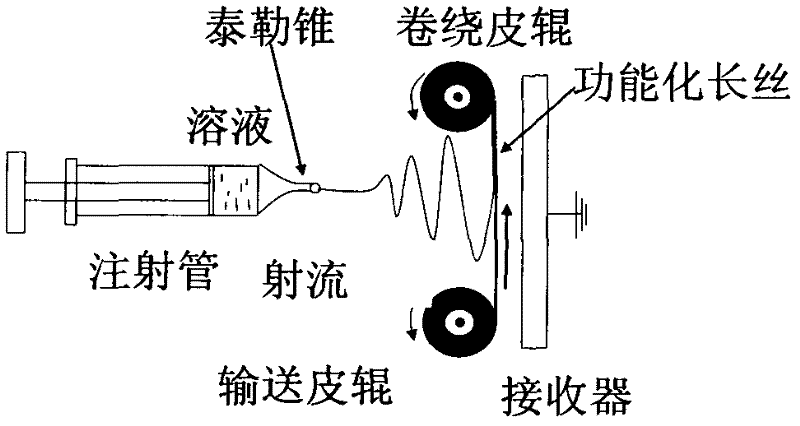

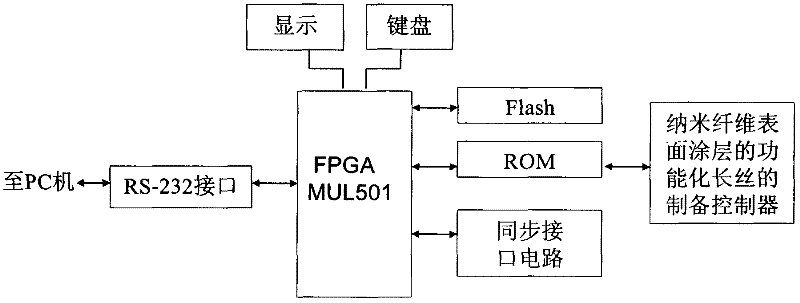

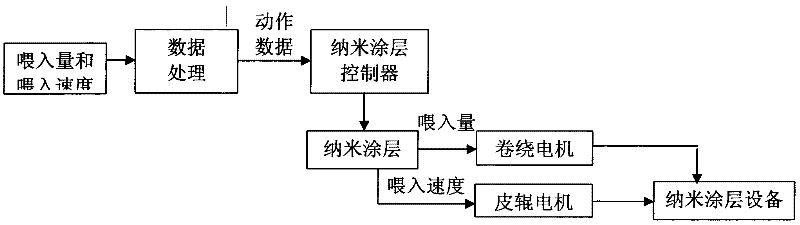

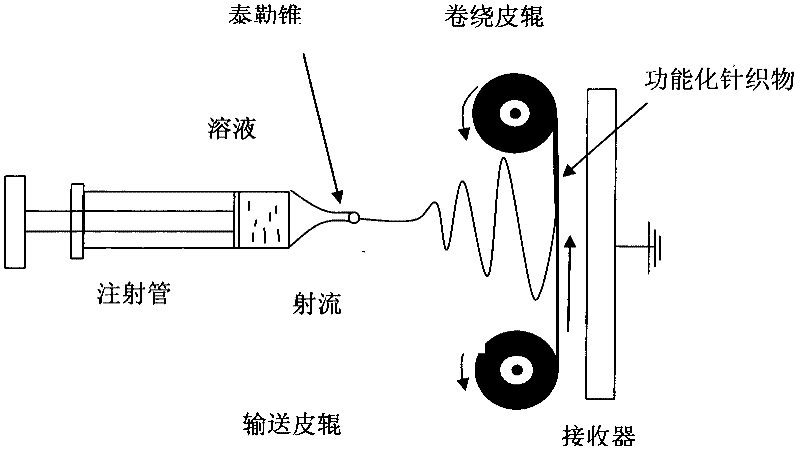

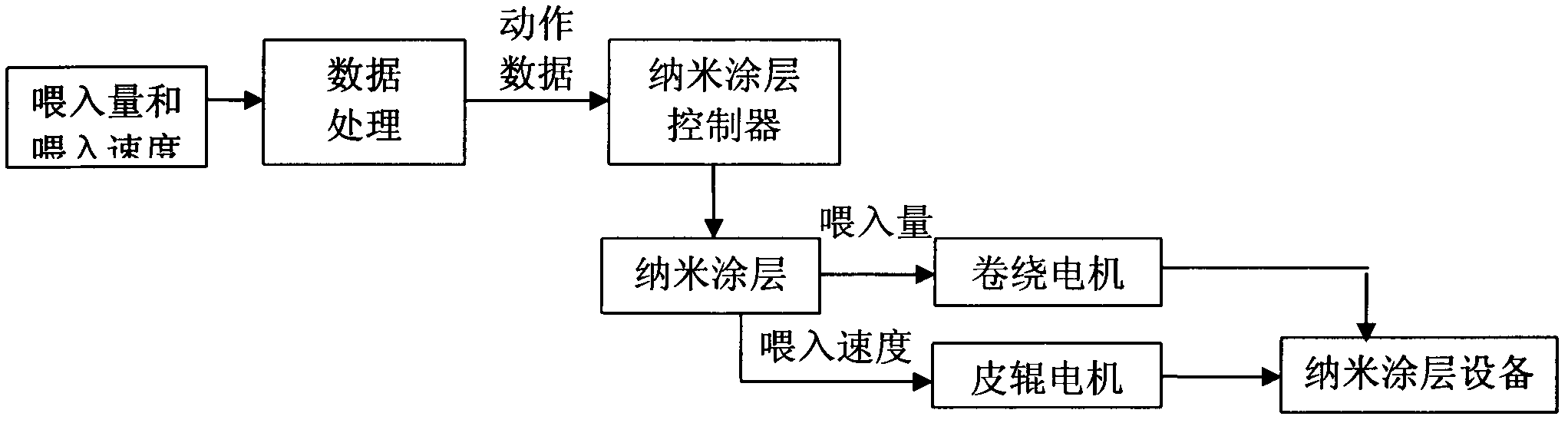

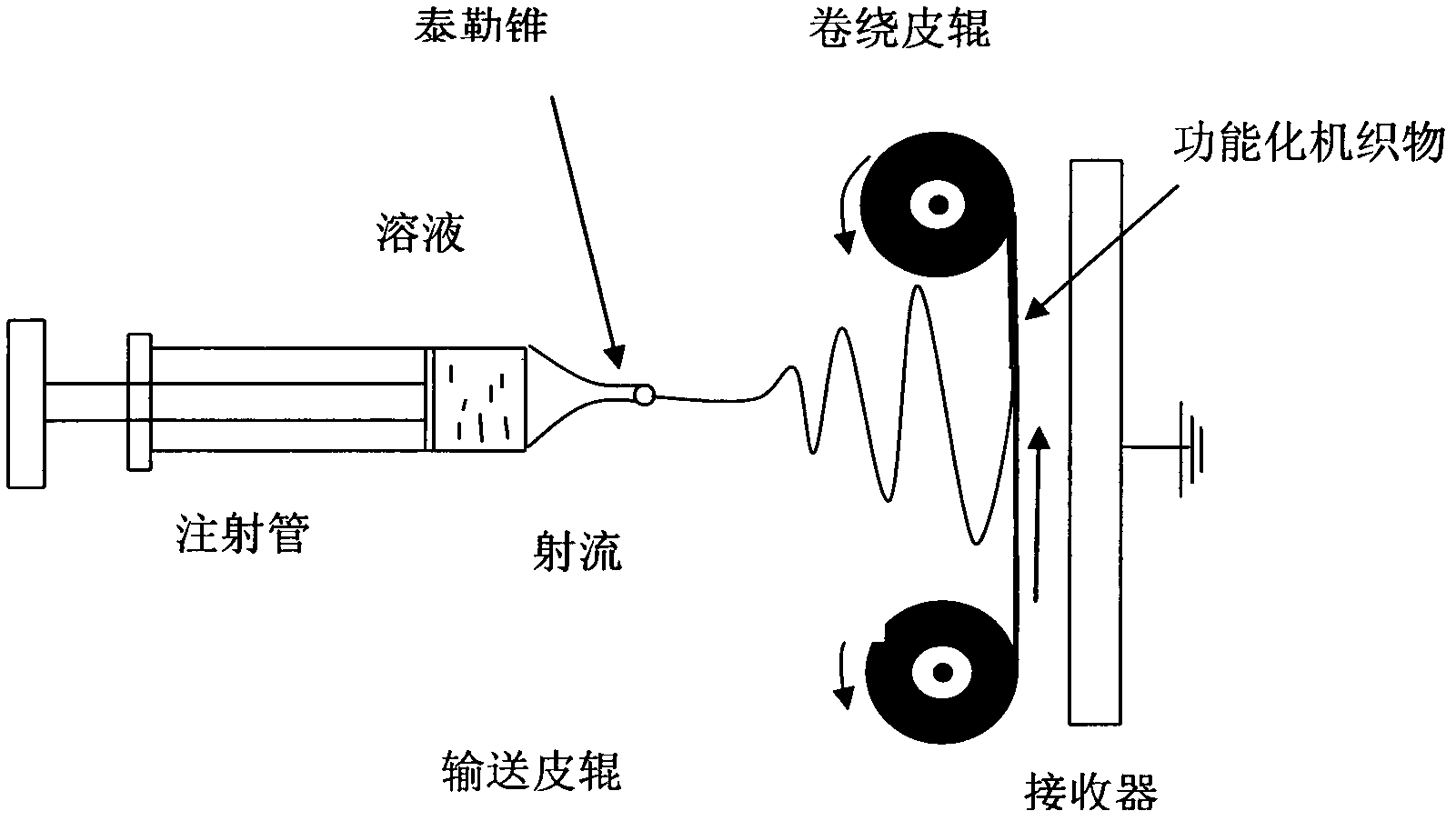

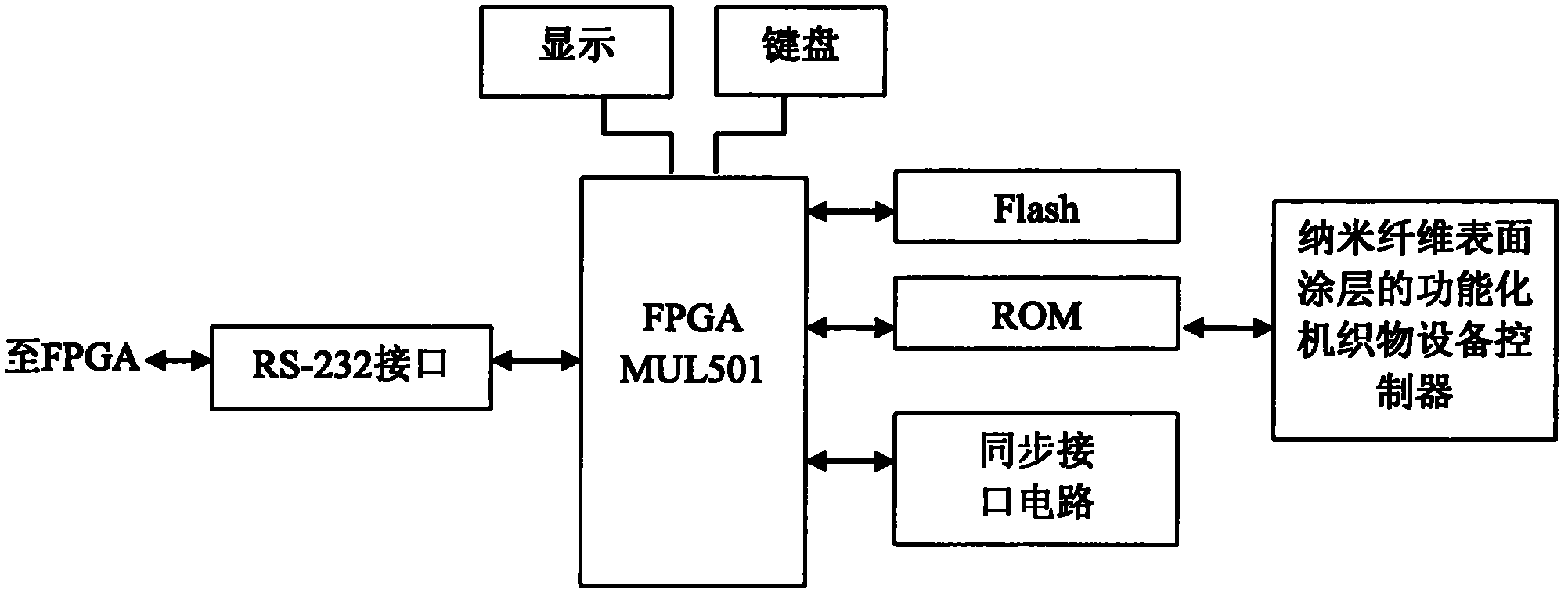

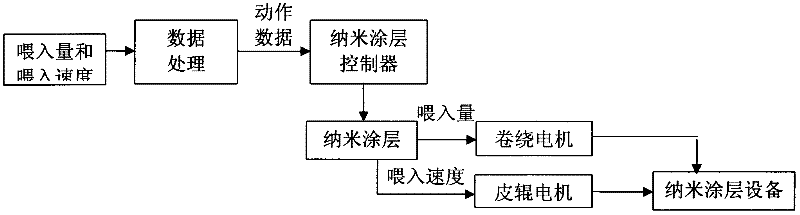

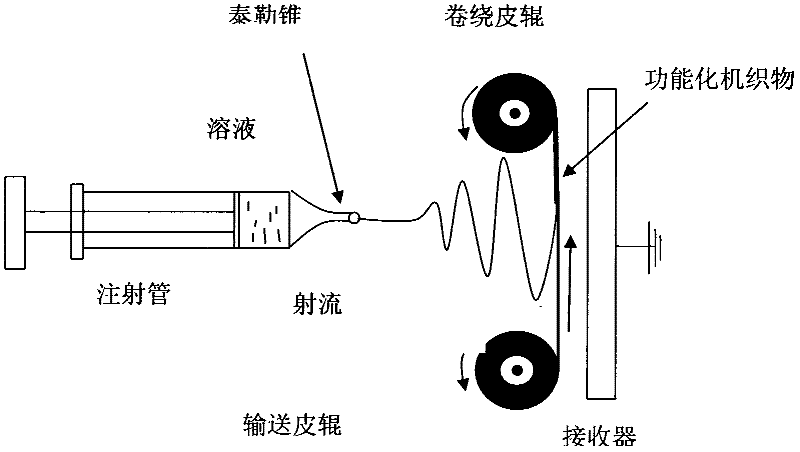

Special DSP (digital signal processor) controller for functional filament equipment with nanofiber surface coatings

InactiveCN102493002AOvercome strengthOvercoming productivityFilament/thread formingYarnFiberControl system

The invention provides a special DSP (digital signal processor) controller for preparing functional filaments with nanofiber surface coatings, belonging to the field of novel textile machinery. The functional filaments with nanofiber surface coatings to be prepared have various types, different processes need to be adjusted in the processing course and the adjustment modes are divided into single adjustment and continuous adjustment, so the feed quantity and feeding speed need to be automatically selected according to the process requirements, and obviously, the manual method can not meet the process requirements. In order to solve the technical problem, in the invention, a DSP is taken as the core of a control system and is used for reading the designed actions of the feed quantity and feeding speed, thus manufacturing different coated products to meet the requirements of functional filament design and further completing production of the filaments with essential functions.

Owner:JIANGNAN UNIV

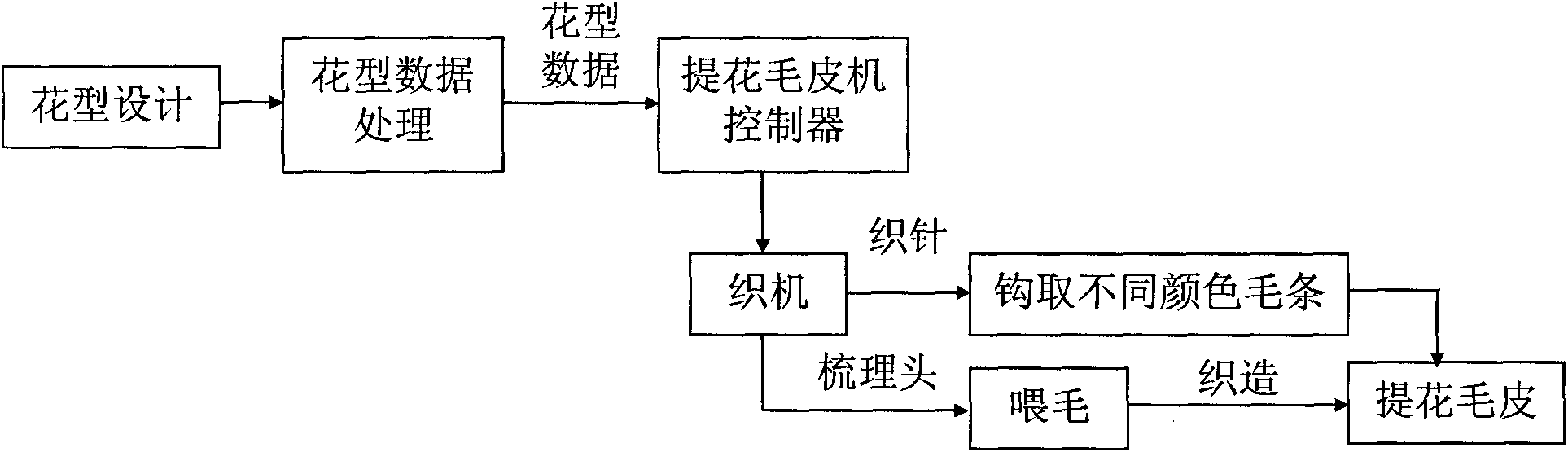

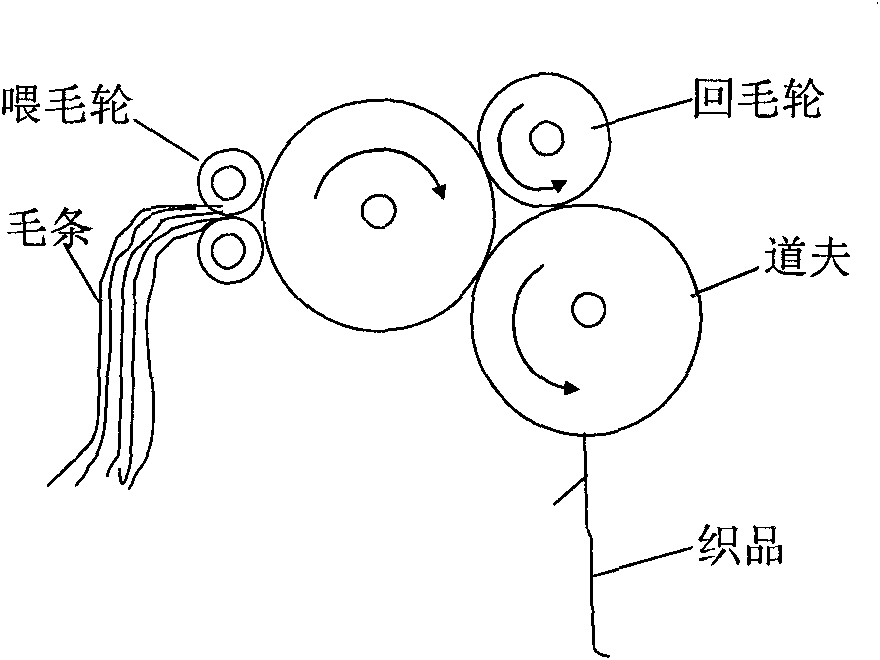

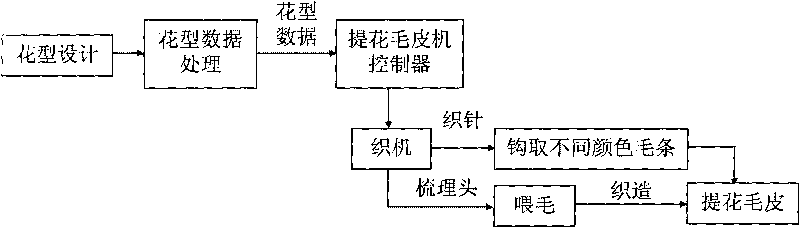

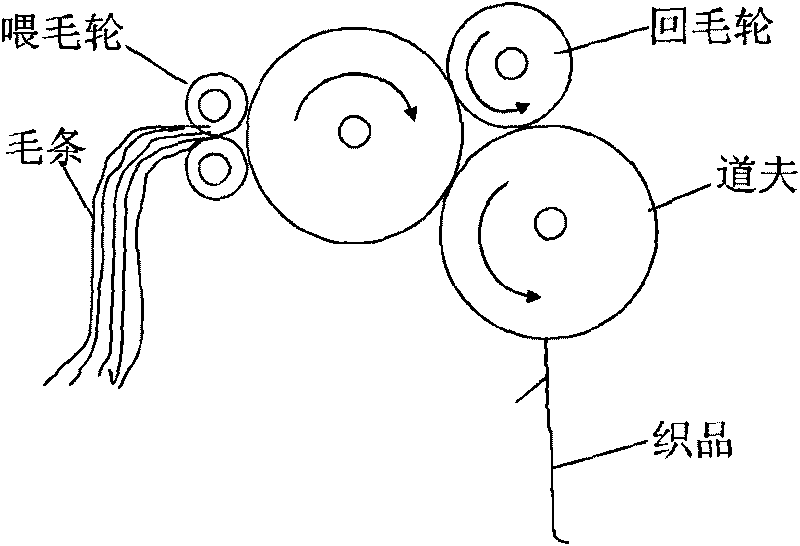

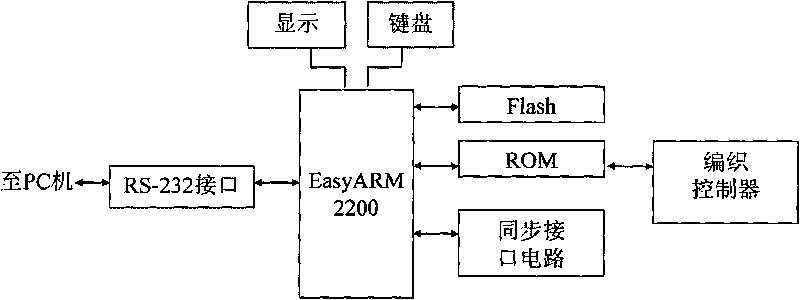

DSP controller special for weaving jacquard fur

InactiveCN101782751AReal-time fully automatic controlEfficient fully automatic controlProgramme controlComputer controlControl systemEngineering

The invention discloses a DSP controller special for weaving jacquard fur, and belongs to the field of novel textile machinery. Products of jacquard fur weaving machines have various patterns, so the color and feeding amount of wool tops are required to be selected automatically according to designed patterns when the wool tops are fed; however, the manual method cannot meet the process requirement obviously. In order to solve the technical problem, a digital signal processor (DSP) is taken as a core of a control system, reads the designed patterns and controls a needle to act according to the data of the patterns, so that the wool tops with various colors are hooked, the requirement of pattern design is met, and the production of the jacquard fur is completed.

Owner:JIANGNAN UNIV

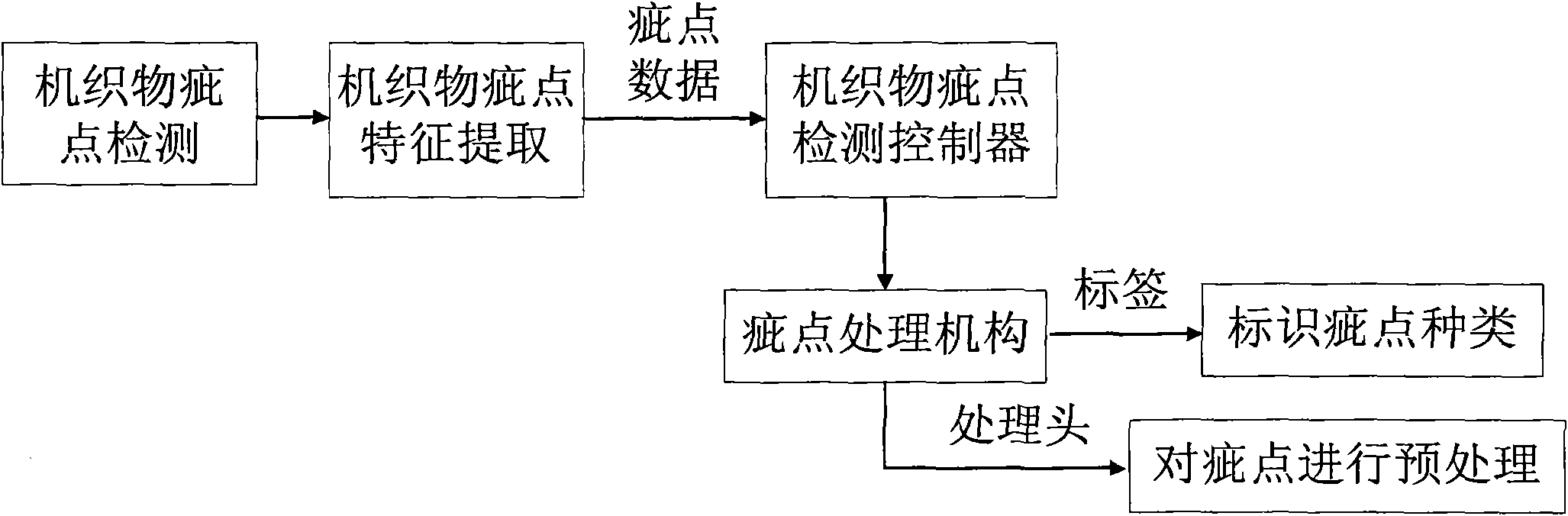

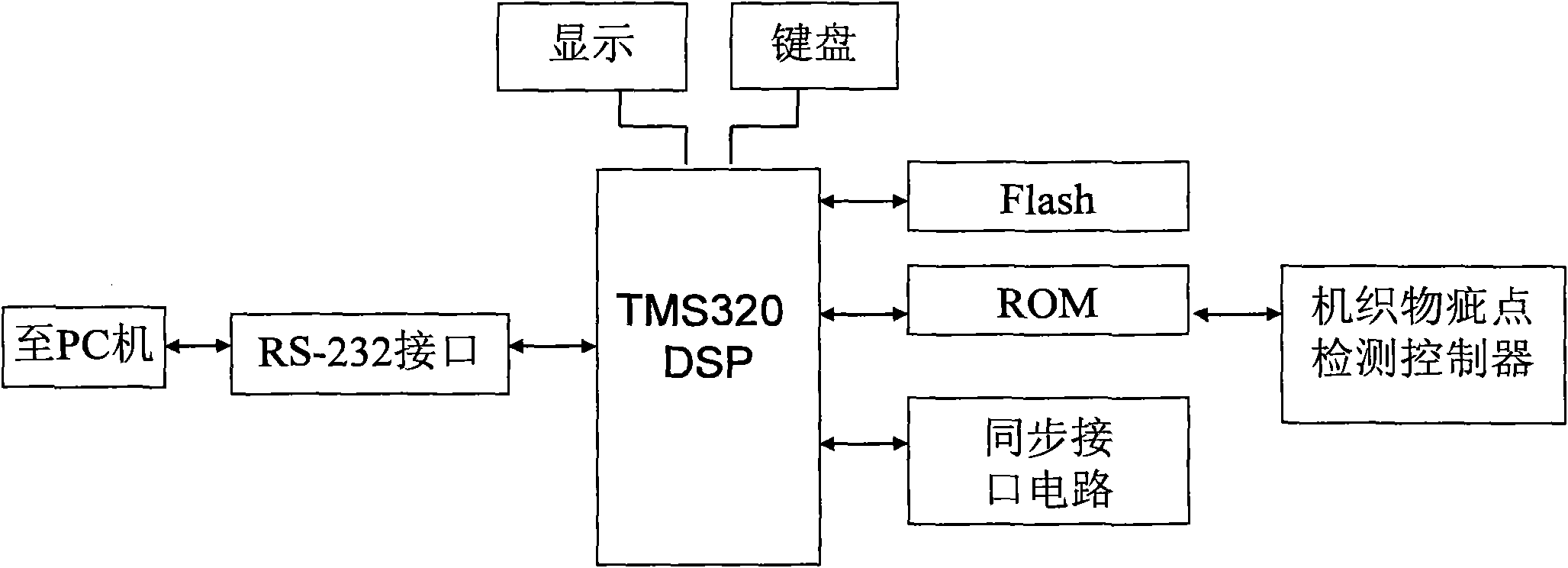

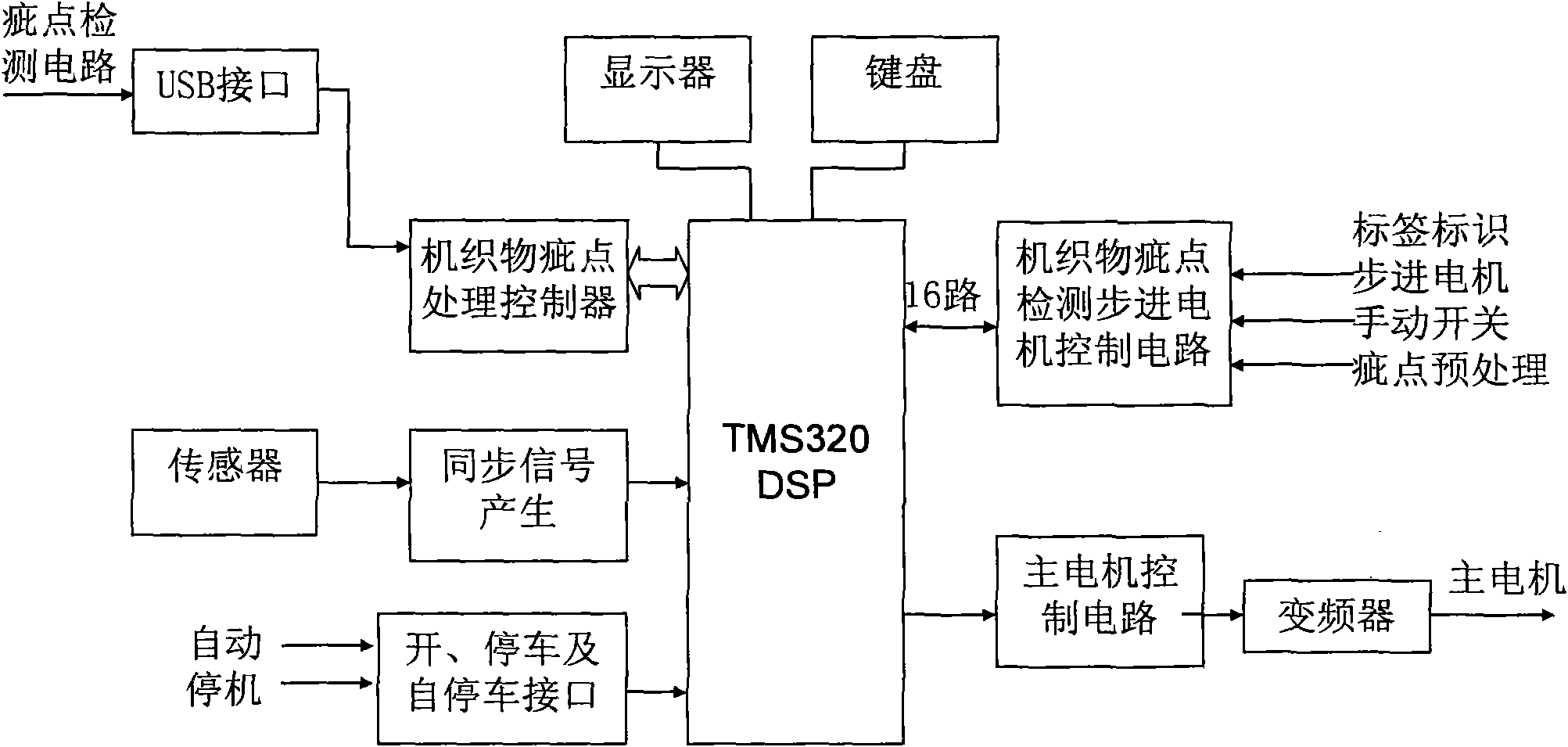

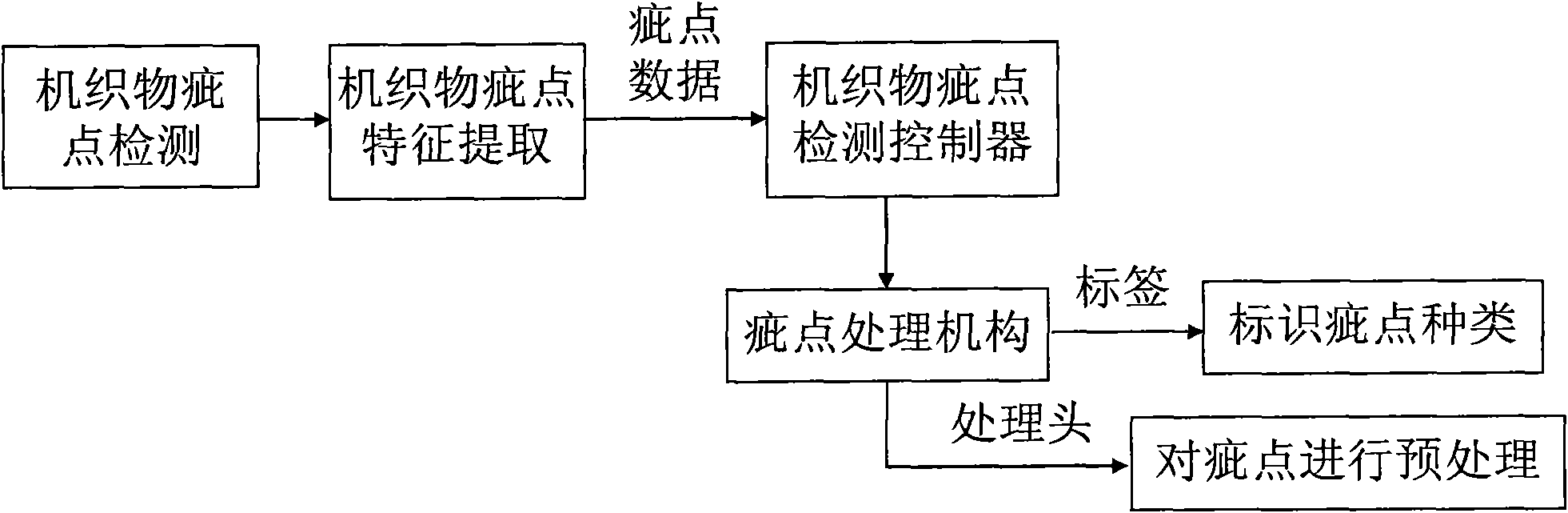

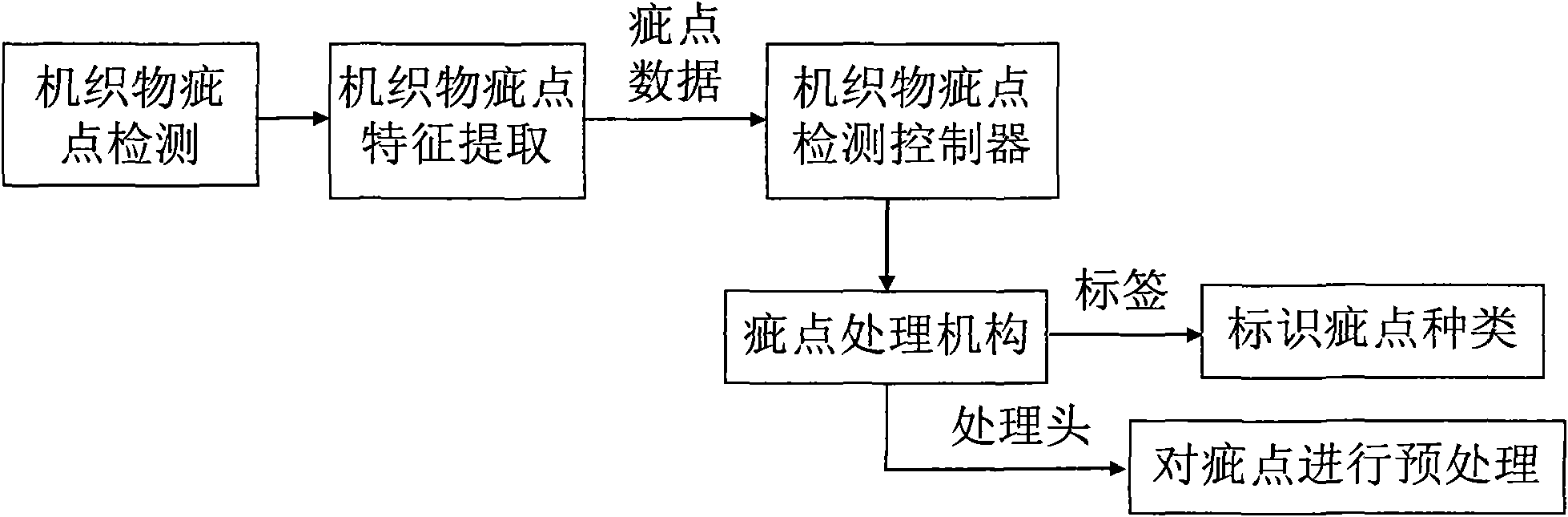

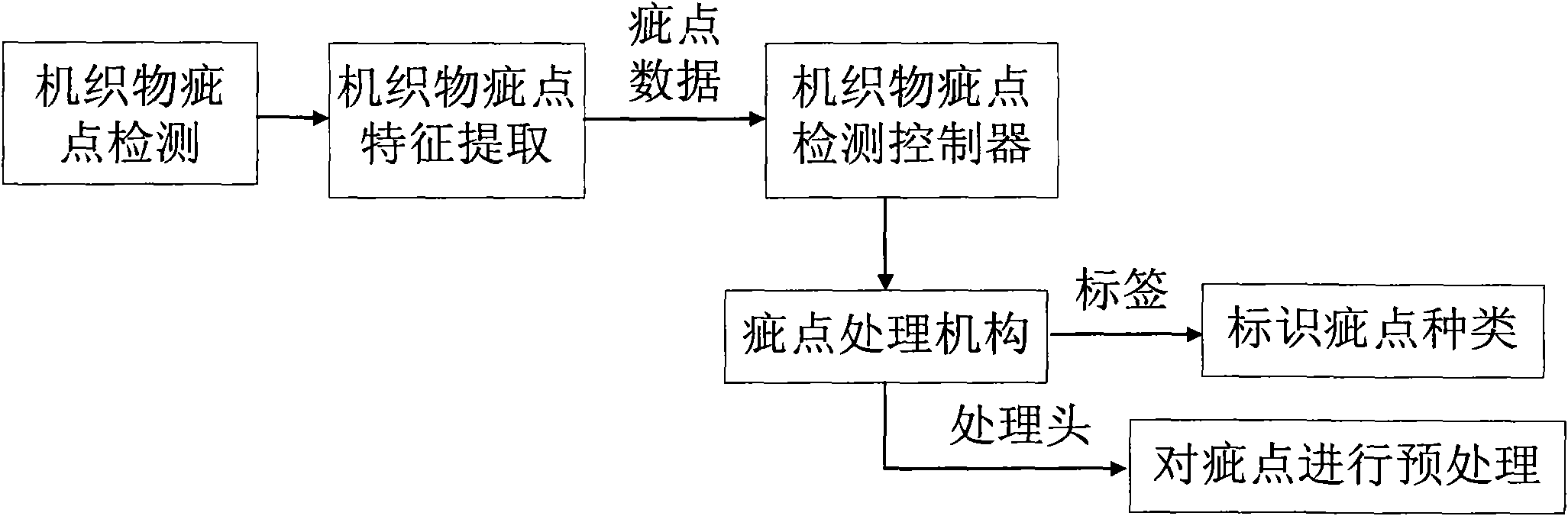

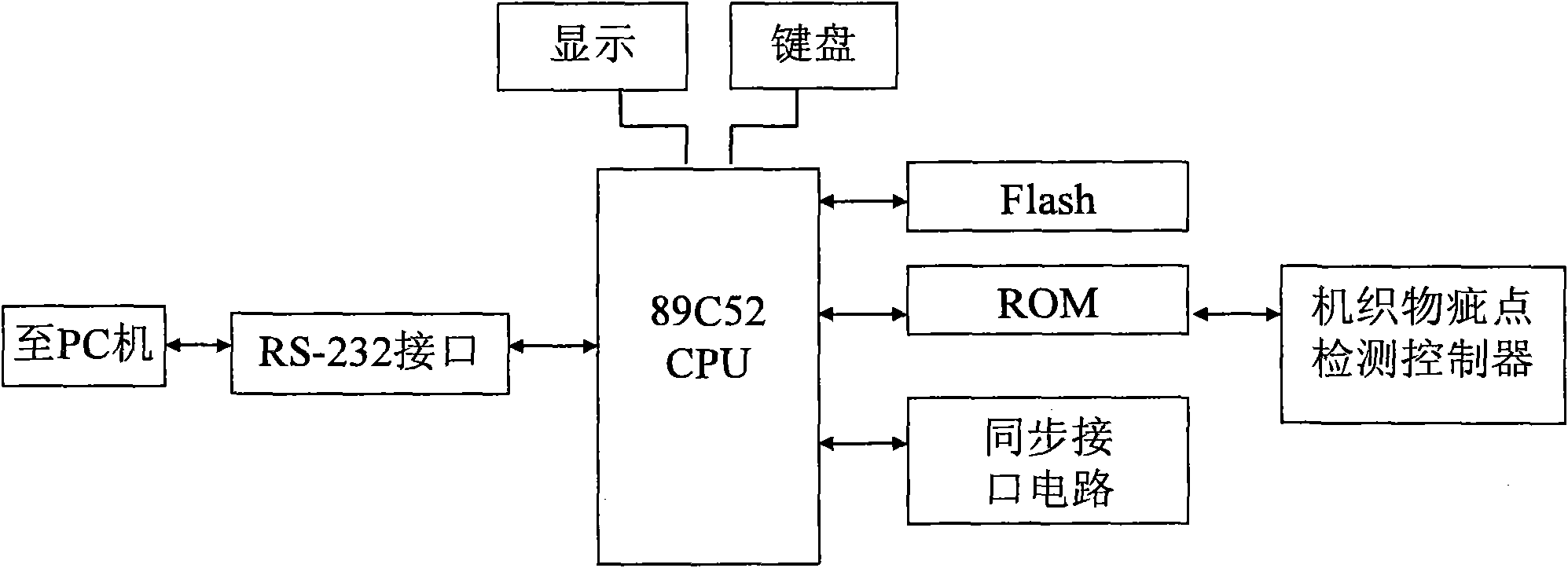

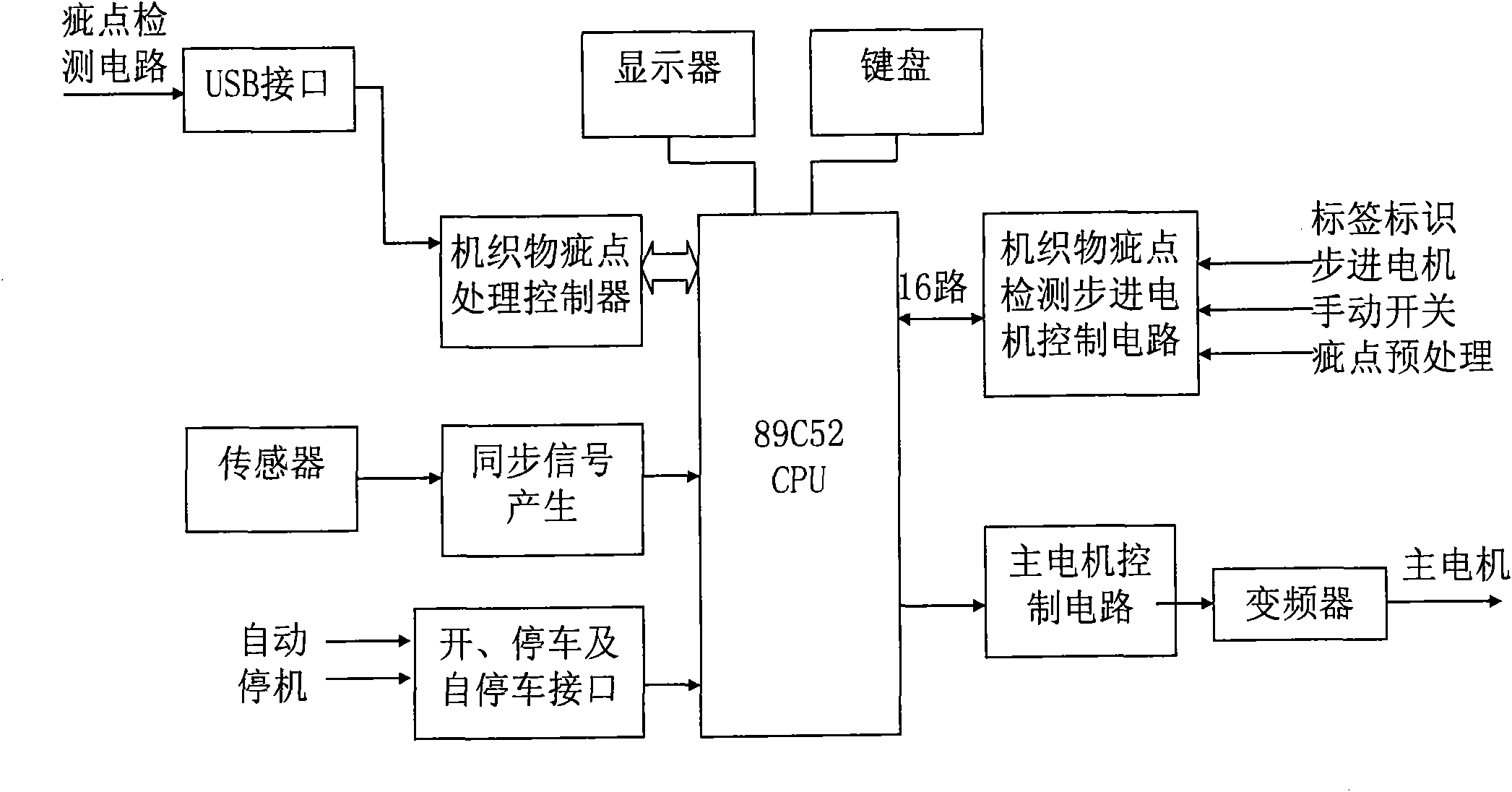

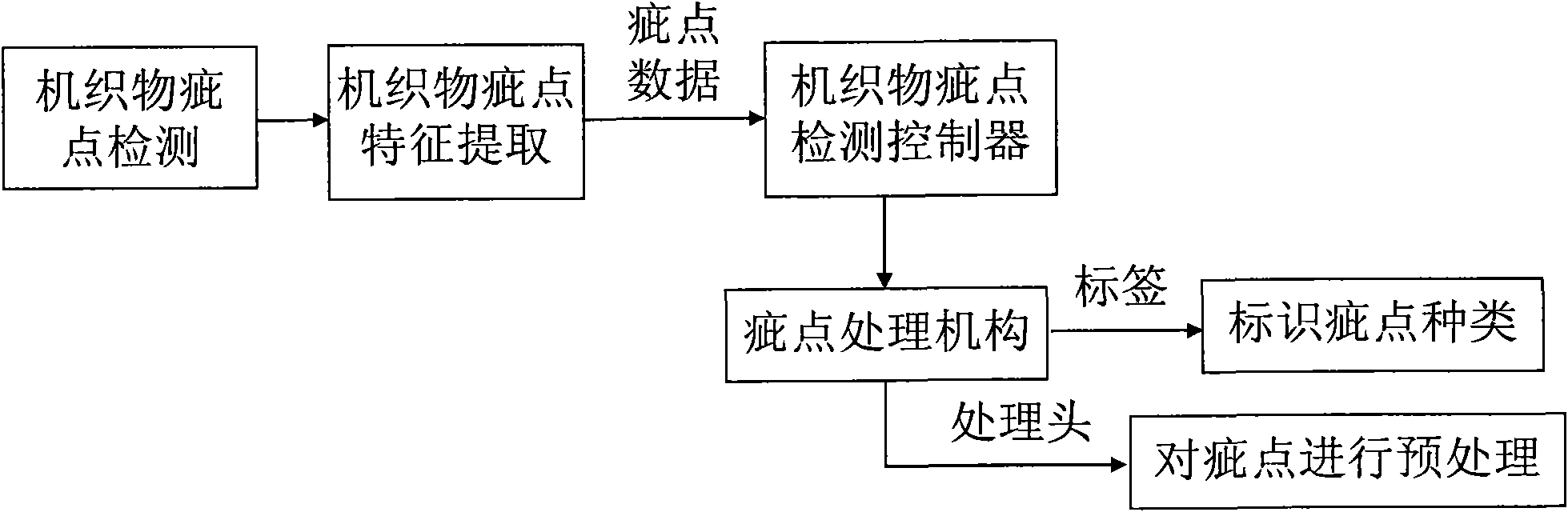

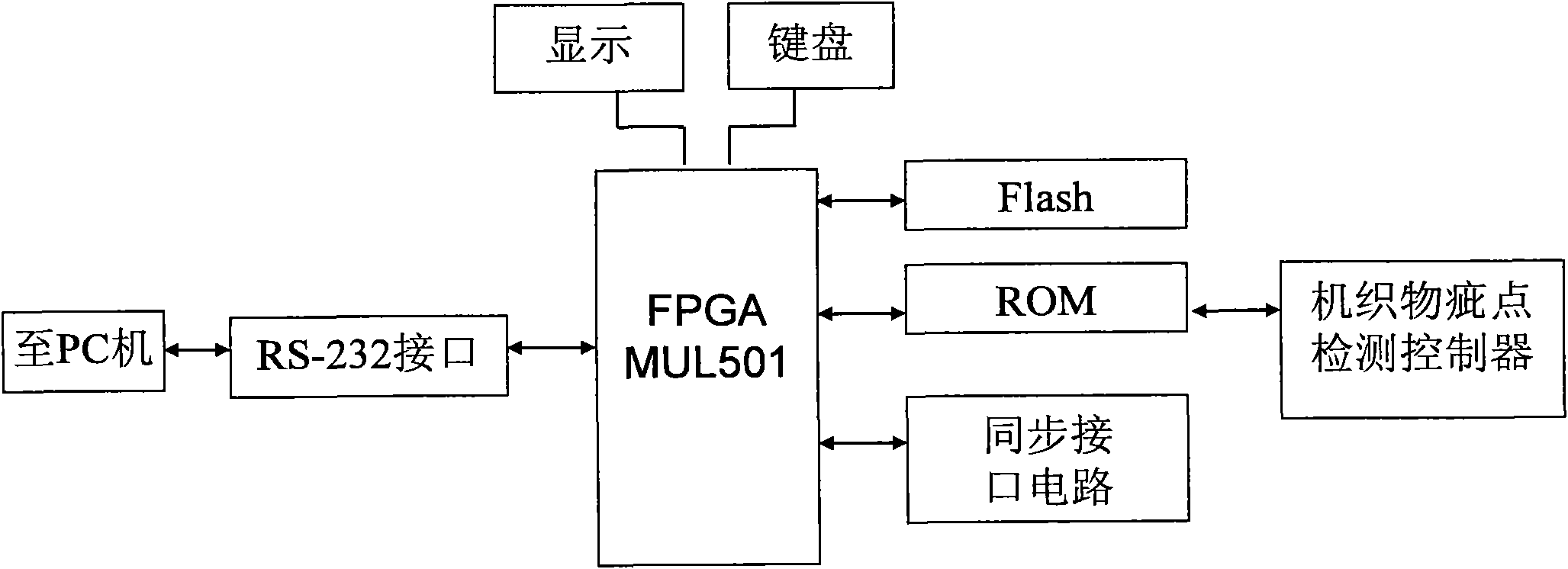

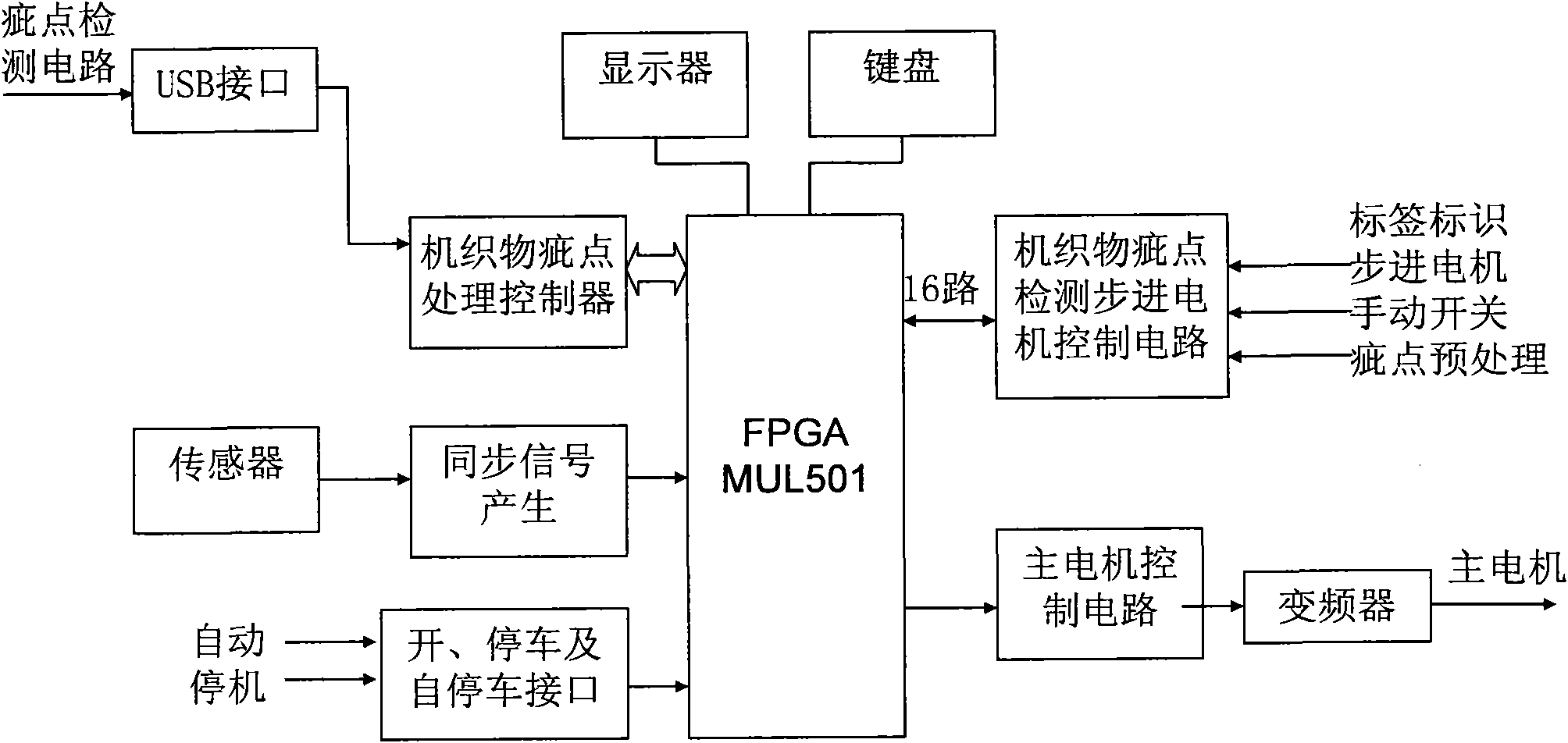

Digital signal processor (DSP) controller special for detecting defects of woven fabrics

InactiveCN102023598AReal-time fully automatic controlEfficient fully automatic controlProgramme controlComputer controlControl systemEngineering

The invention discloses a digital signal processor (DSP) controller special for detecting defects of woven fabrics, belonging to the field of novel textile machinery. The woven fabrics have the defects of wide varieties and complex detection algorithm, so the specific defect treatment flow is needed to be selected according to the varieties and relevant characteristics of the defects during defect detection. By adopting a simple single software treatment method, the real-time control requirement of defect detection can not be met obviously. In order to solve the technical problem, in the invention, a DSP is taken as the core of a control system and is used for reading the varieties and relevant characteristics of the defects and controlling the subsequent treatment flows of the defects of the woven fabrics so as to meet the real-time control requirement of defect detection treatment, thus completing the treatment flows of the defects of the woven fabrics.

Owner:JIANGNAN UNIV

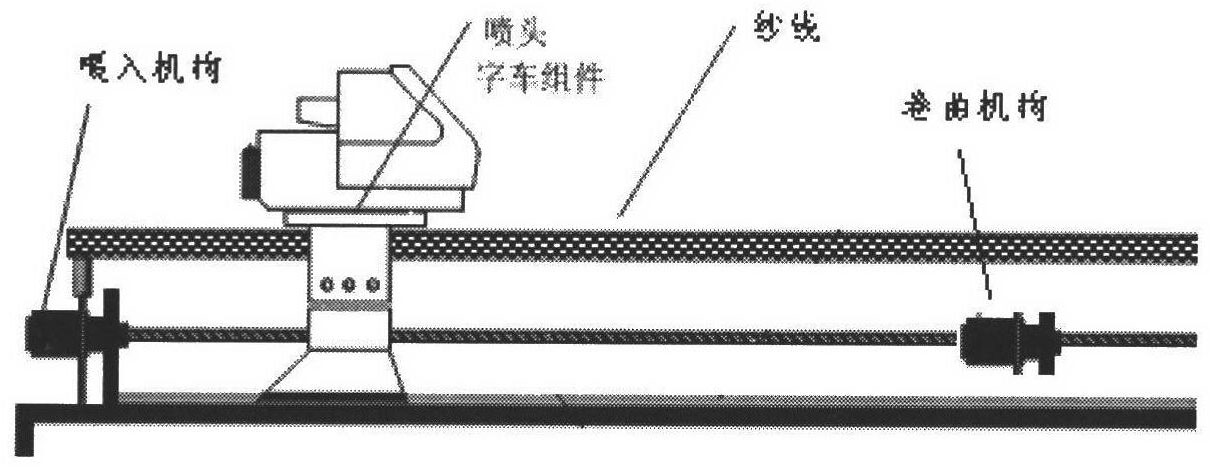

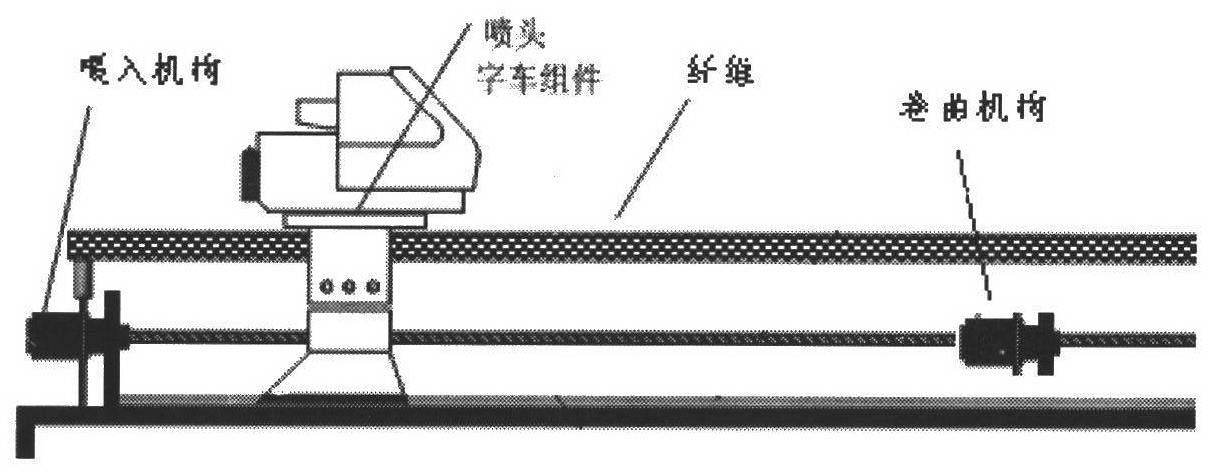

Fiber ink-jet printing equipment

InactiveCN102490499AReal-time fully automatic controlTypewritersOther printing apparatusFiberComputer engineering

Aiming at the current domestic ink-jet printer, the invention provides fiber ink-jet printing equipment. For the fiber ink-jet printing equipment, a winding mechanism is utilized for realizing continuous feeding and take-up of fiber, so that an image set by a computer can be conveniently printed on the surface of the fiber, and finally the surface of the fiber is ensured to have different patterns. The invention provides the novel mechanism, so that a new function is provided for the ink-jet printer.

Owner:JIANGNAN UNIV

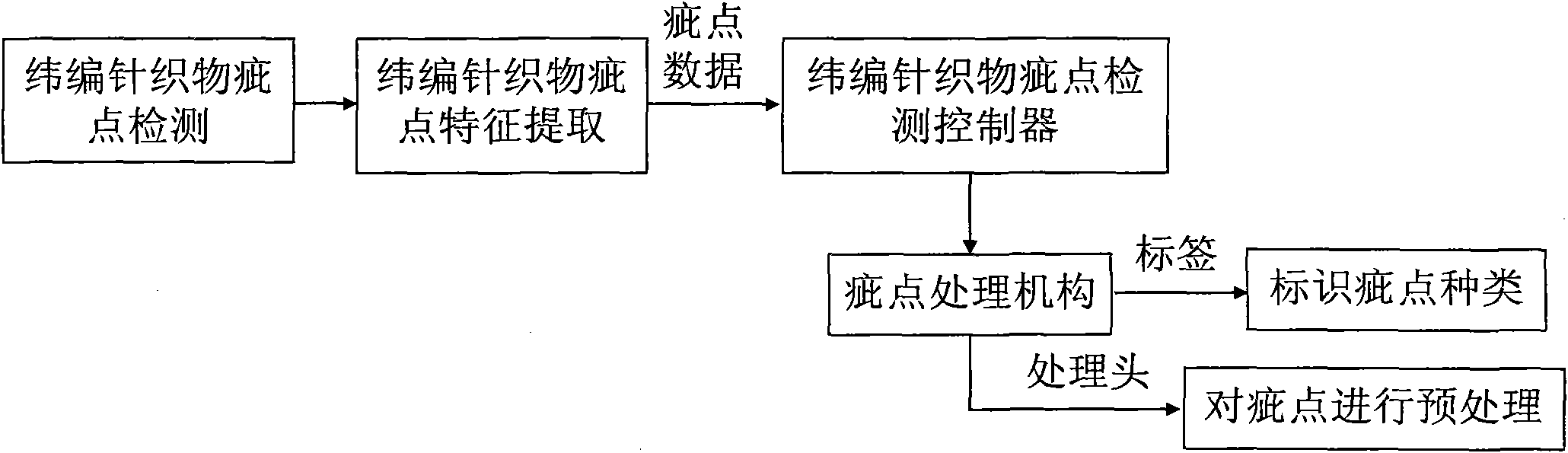

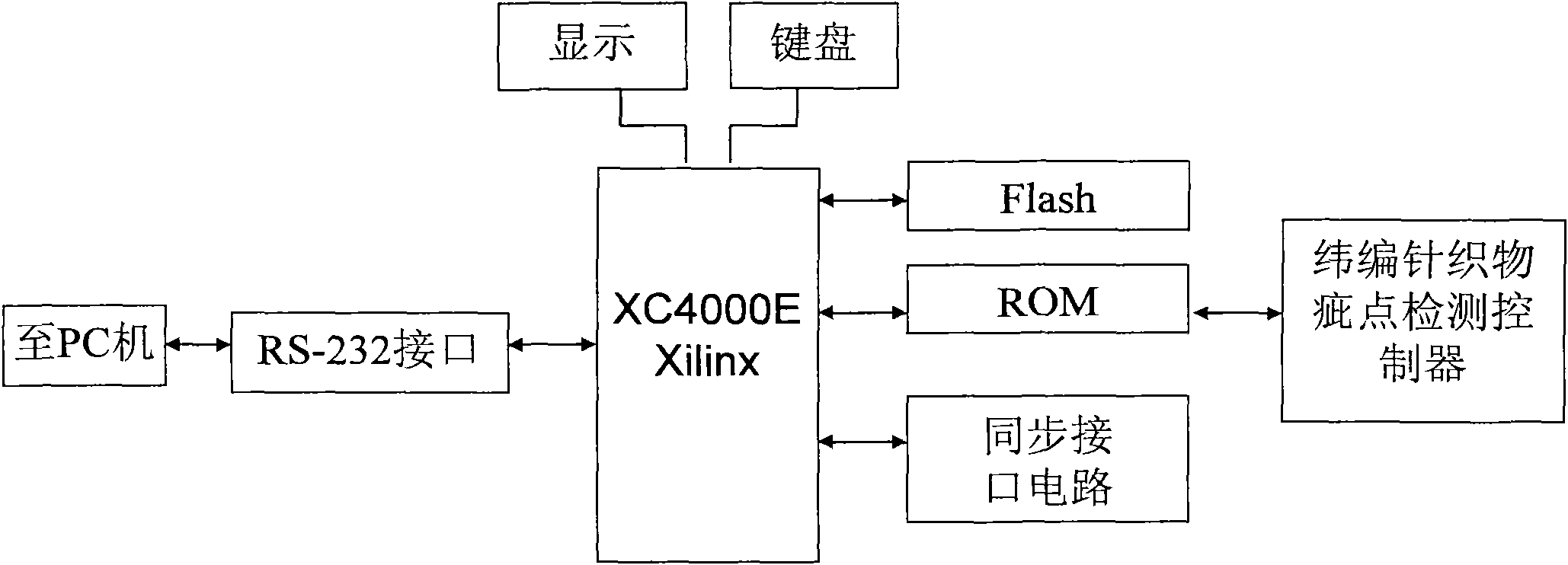

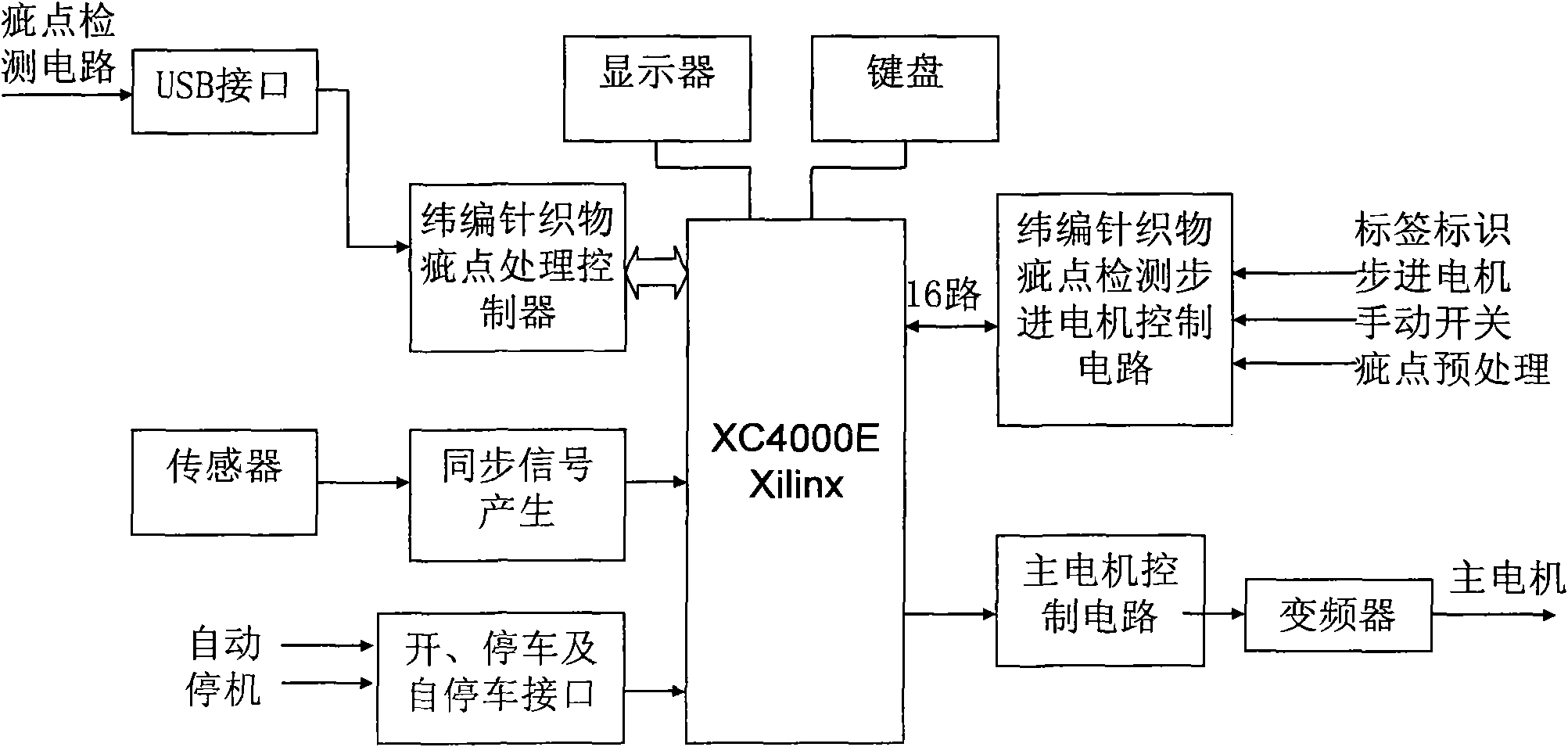

CPLD controller special for detecting defects of weft-knitted fabrics

InactiveCN102012677AReal-time fully automatic controlProgramme control in sequence/logic controllersControl systemEngineering

A CPLD controller special for detecting defects of weft-knitted fabrics belongs to the field of novel textile machinery. The defects of weft-knitted fabrics are characterized by wide varieties and complex detection algorithm, so the specific detect treatment flow needs to be selected according to the variety and relevant characteristics of the defects during defect detection. Adopting simple single software treatment method obviously can not meet the real-time control requirement of defect detection. In order to solve the technical problem, in the invention, CPLD is taken as the core of a control system and a CPLD system is used for reading the variety and relevant characteristics of the defects and controlling the subsequent treatment flow of the defects of weft-knitted fabrics so as to meet the real-time control requirement of defect detection treatment, thus completing the treatment flow of the defects of weft-knitted fabrics.

Owner:JIANGNAN UNIV

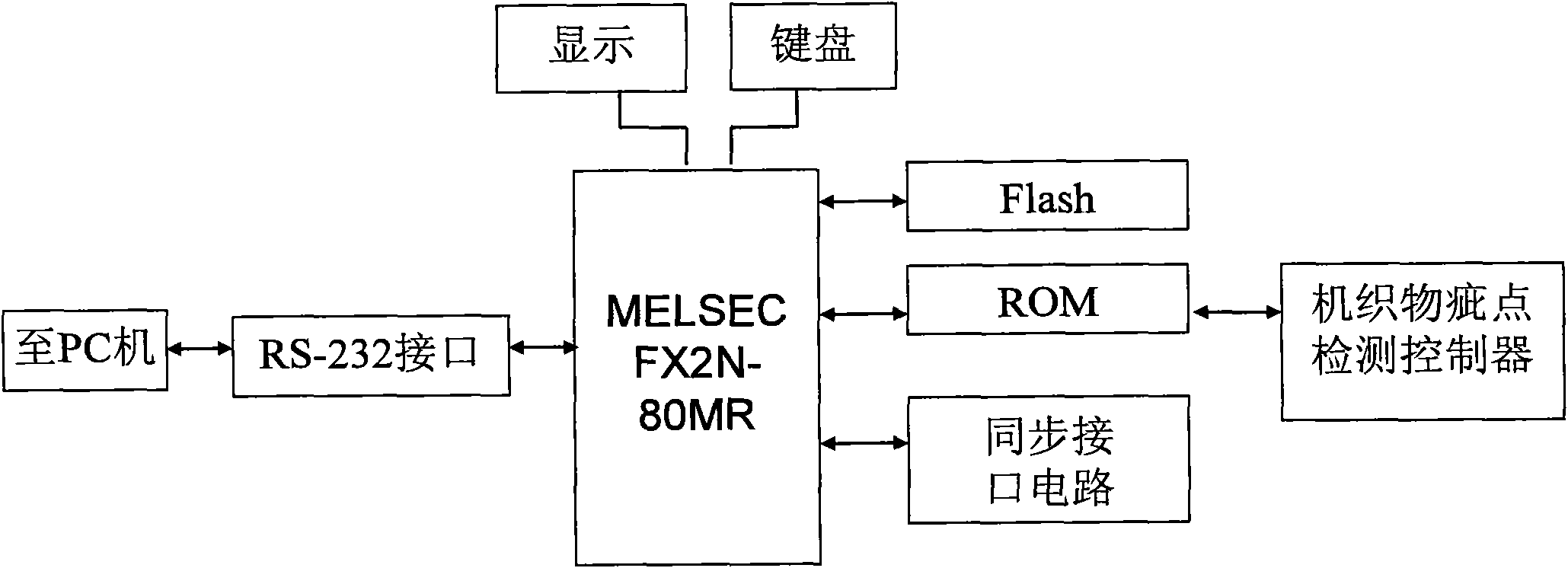

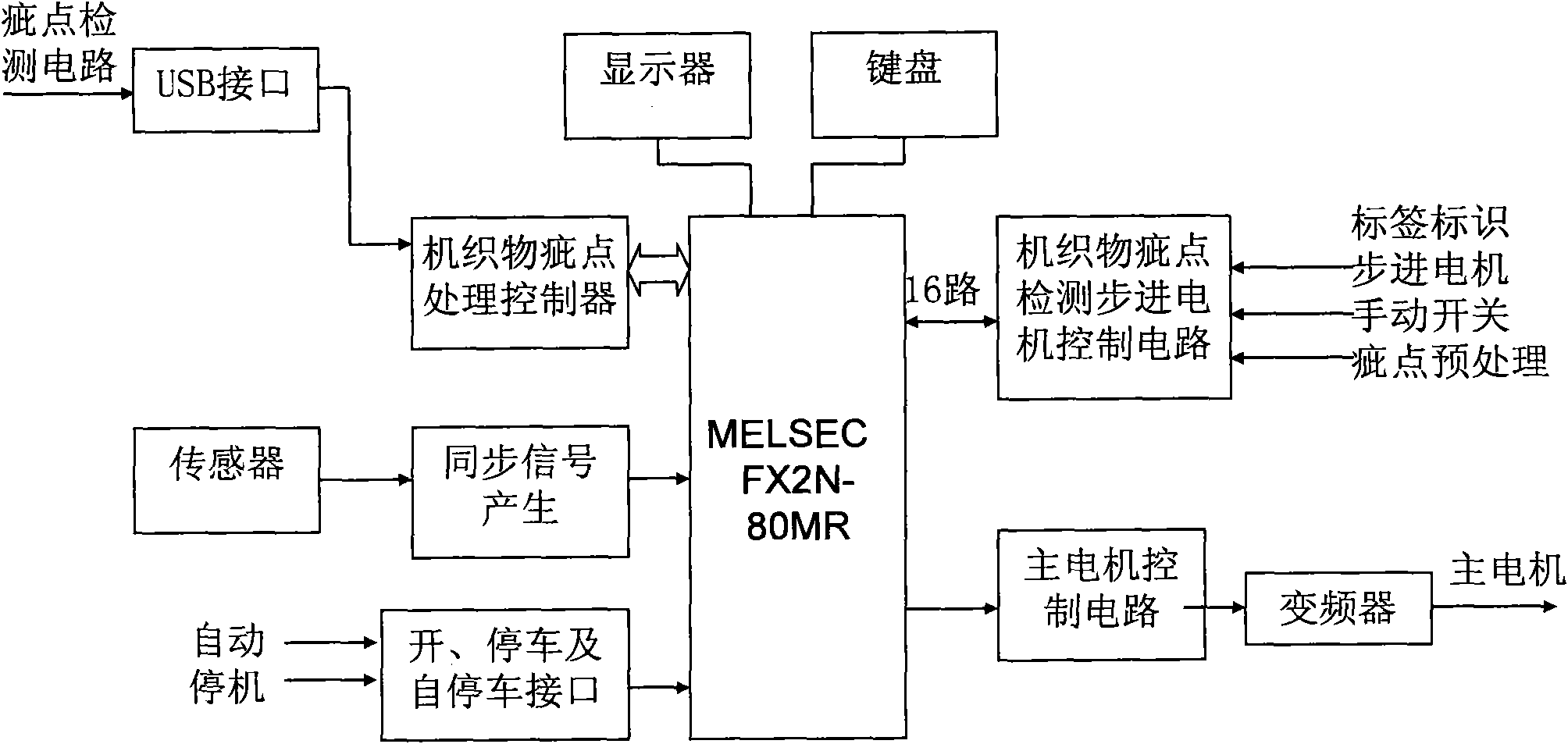

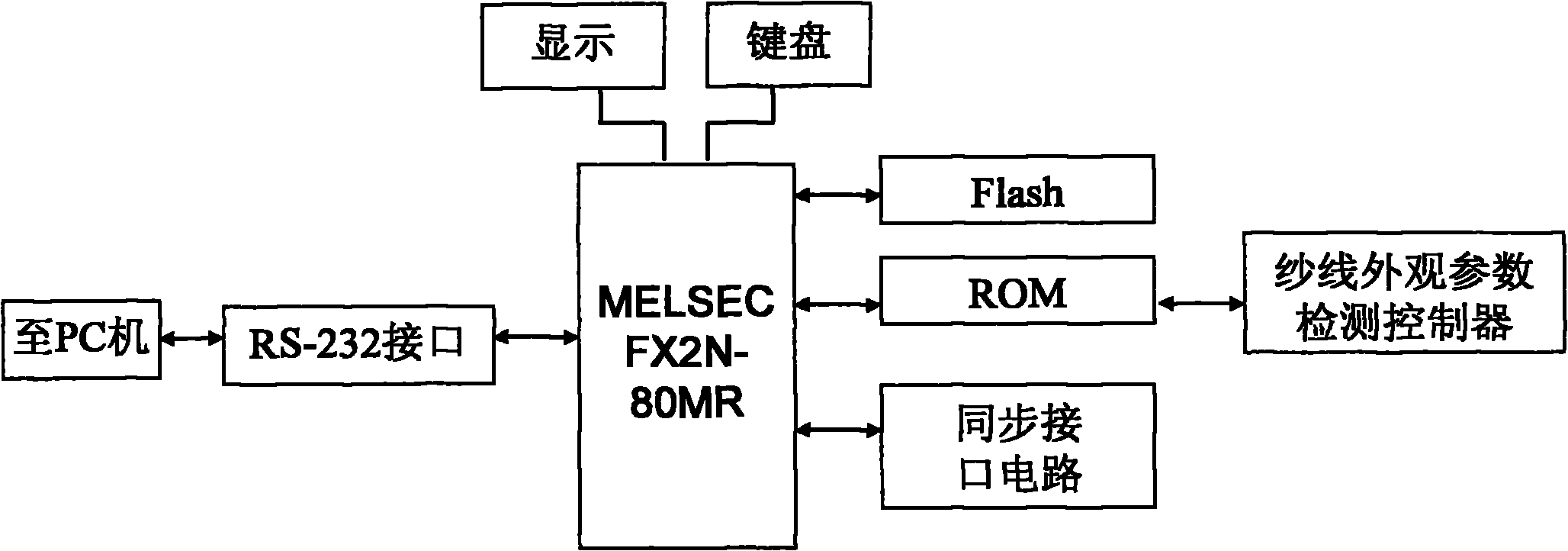

Programmable logic controller (PLC) special for detecting defects of woven fabrics

InactiveCN102023607ARealize fully automatic controlReal-time fully automatic controlProgramme control in sequence/logic controllersControl systemProgrammable logic controller

The invention provides a programmable logic controller (PLC) special for detecting defects of woven fabrics, belonging to the field of novel textile machinery. The woven fabrics have the defects of wide varieties and complex detection algorithm, so the specific defect treatment flow is needed to be selected according to the varieties and relevant characteristics of the defects during defect detection. By adopting a simple single software treatment method, the real-time control requirement of defect detection can not be met. In order to solve the technical problem, in the invention, the PLC is taken as the core of a control system, and a PLC system is used for reading the varieties and relevant characteristics of the defects and controlling the subsequent treatment flows of the defects of the woven fabrics so as to meet the real-time control requirement of defect detection treatment, thus completing the treatment flows of the defects of the woven fabrics.

Owner:JIANGNAN UNIV

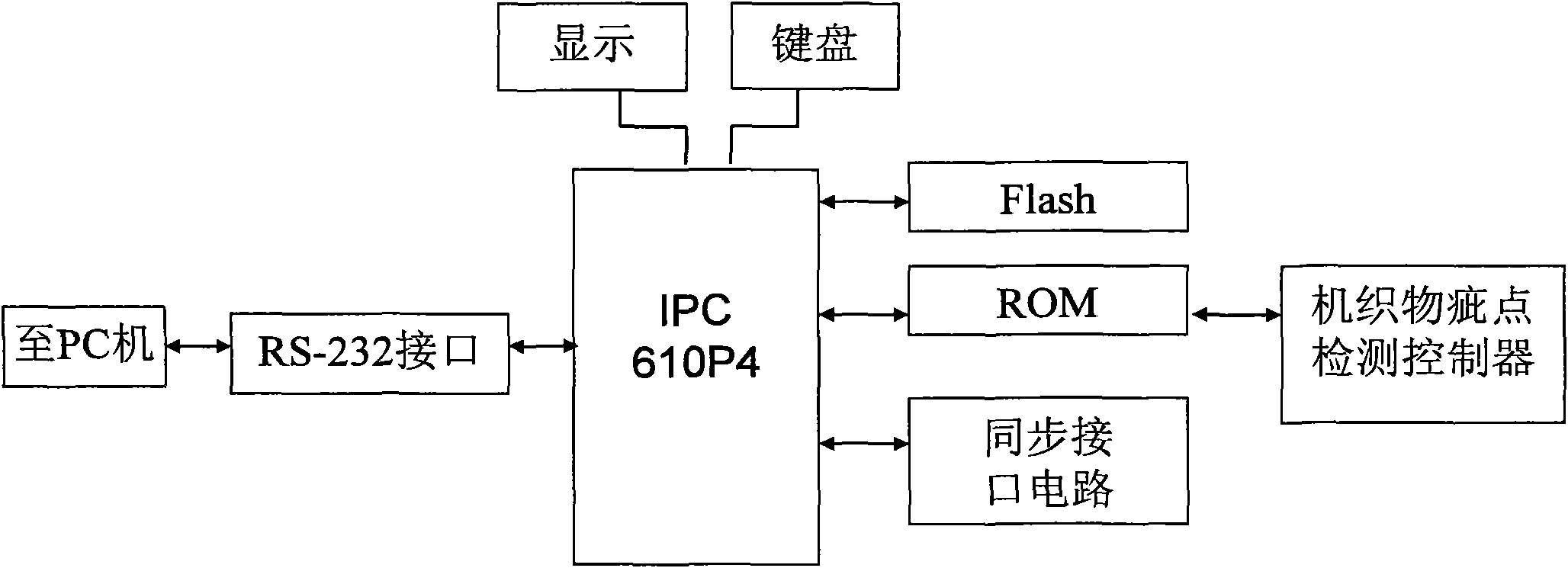

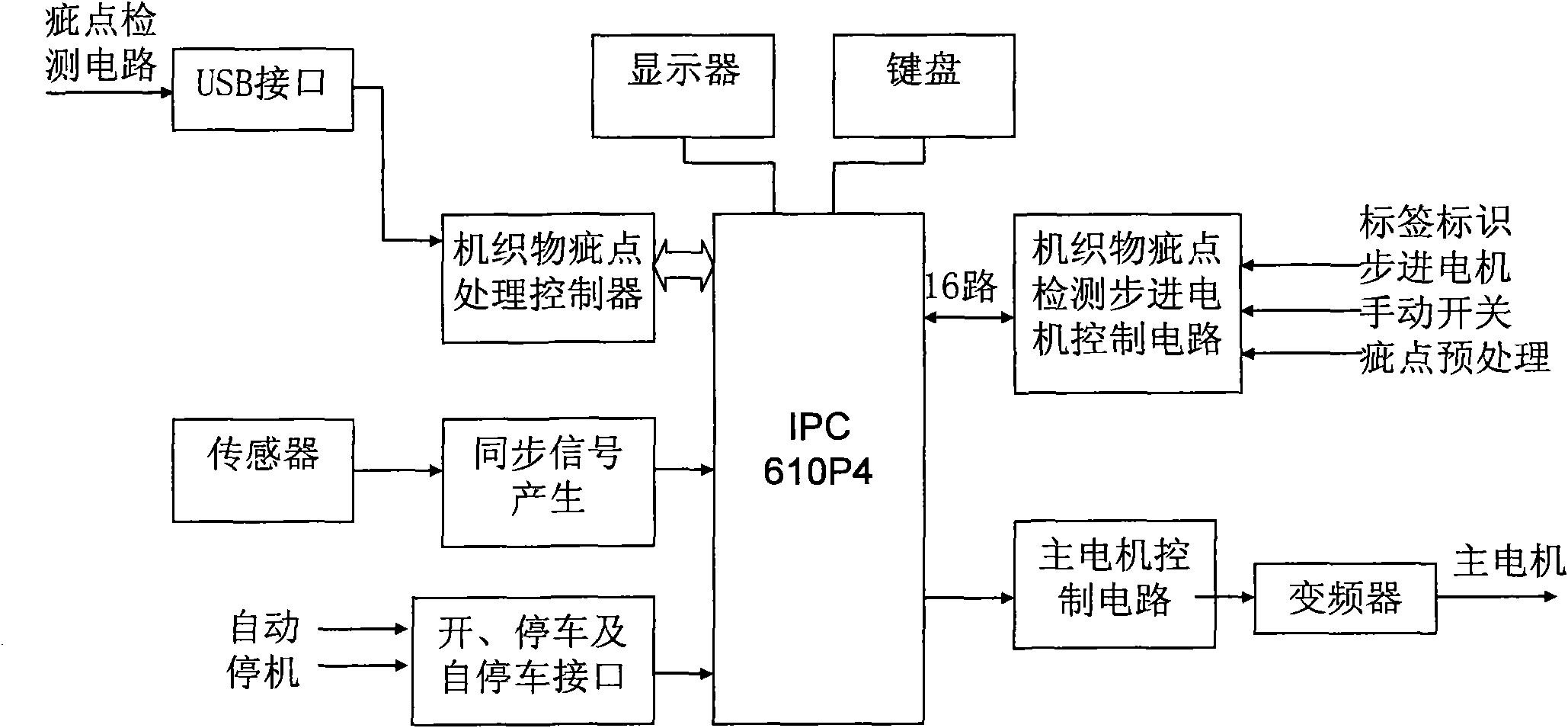

Industrial process control (IPC) controller special for detecting woven fabric defects

InactiveCN102023590ARealize fully automatic controlReal-time fully automatic controlProgramme control in sequence/logic controllersWoven fabricRelevant feature

The invention discloses an industrial process control (IPC) controller special for detecting woven fabric defects, which belongs to the field of novel spinning machinery. Since various types of the woven fabric defects exist and a detection algorithm is complicated, a specific defect processing flow needs to be selected according to the types of defects and relevant characteristics during defect detection and the requirement of defect detection on real-time control cannot be met by a simple unique software processing method. In order to solve the technical problem, the IPC is taken as the core of a control system and an IPC system reads the types and relevant characteristics of the defects and controls subsequent processing flow of the woven fabric defects, so that the requirement of defect detection on real-time control is met and the processing flow of the woven fabric defects is finished.

Owner:JIANGNAN UNIV

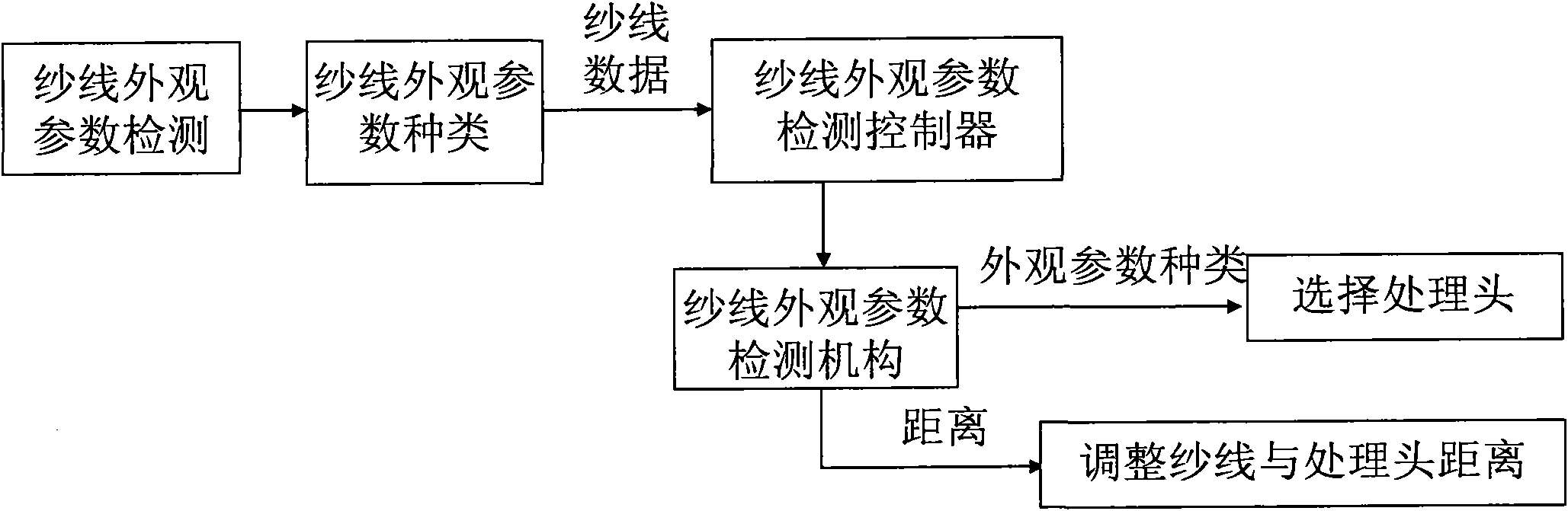

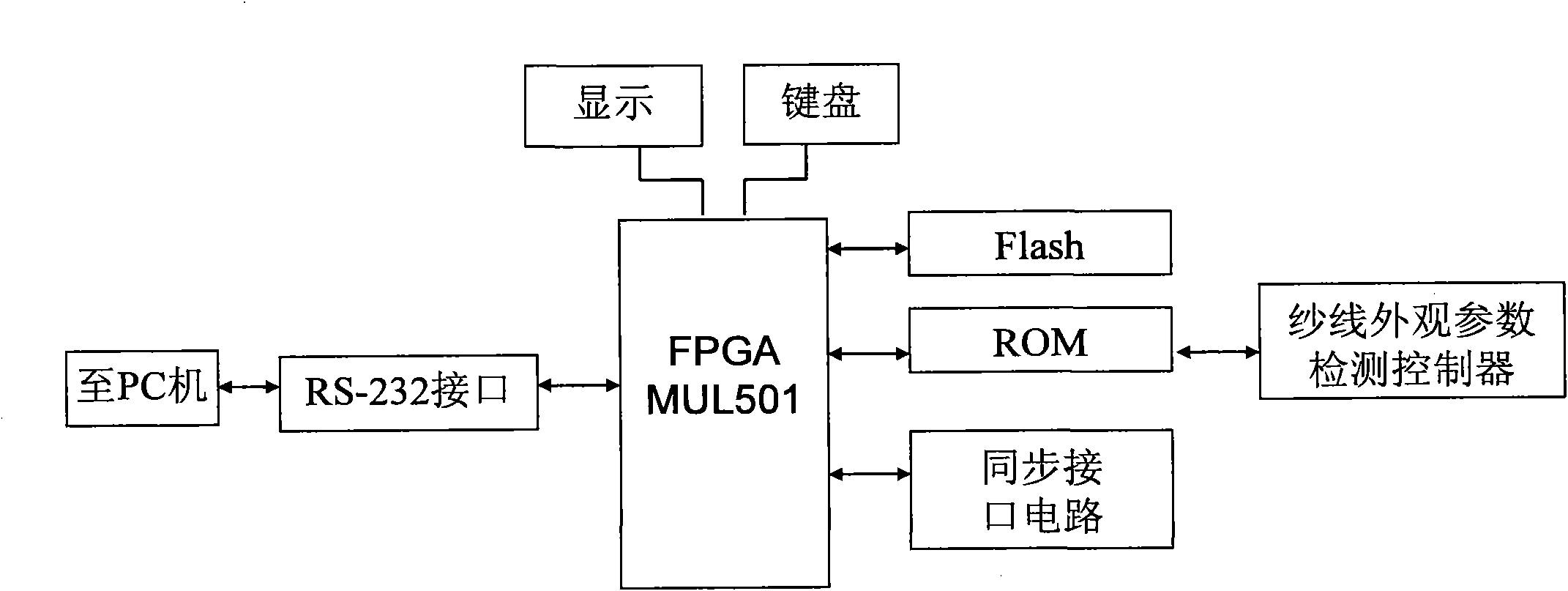

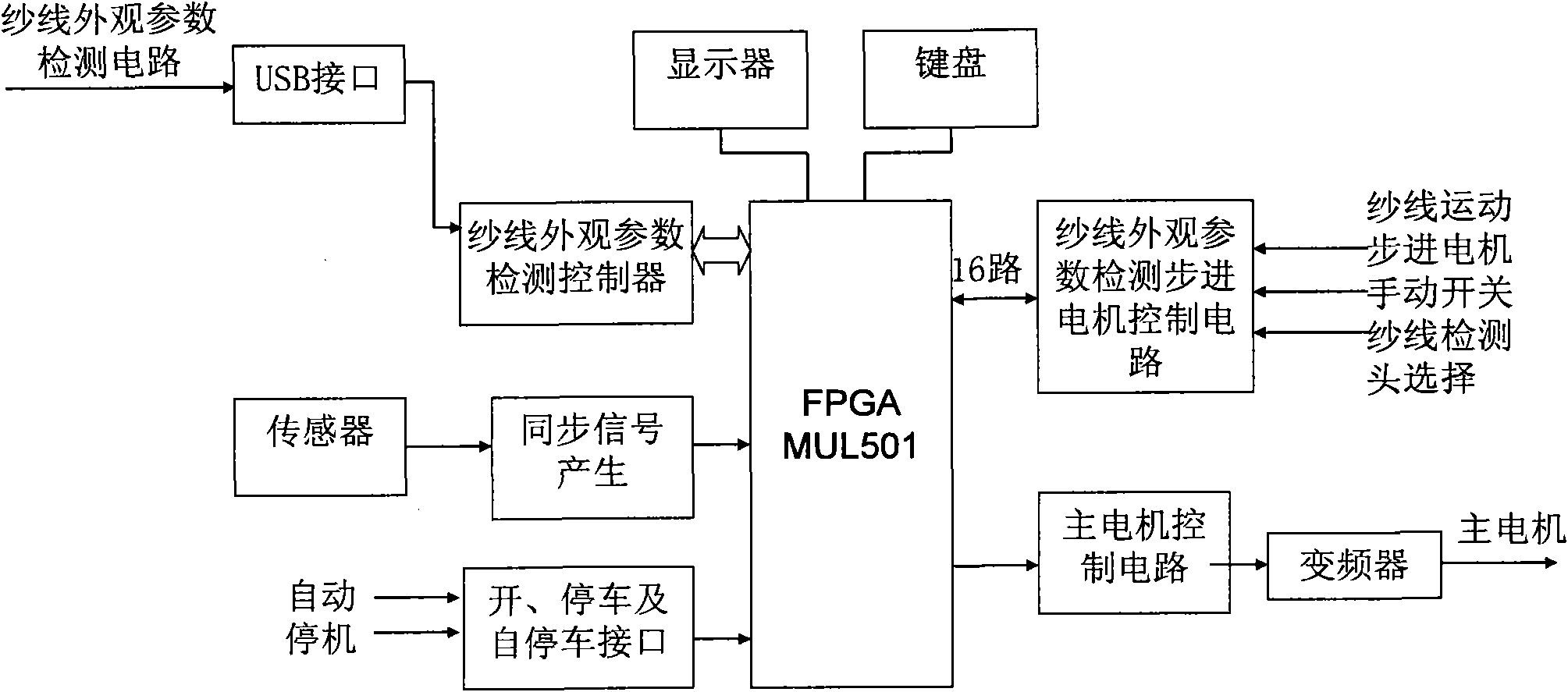

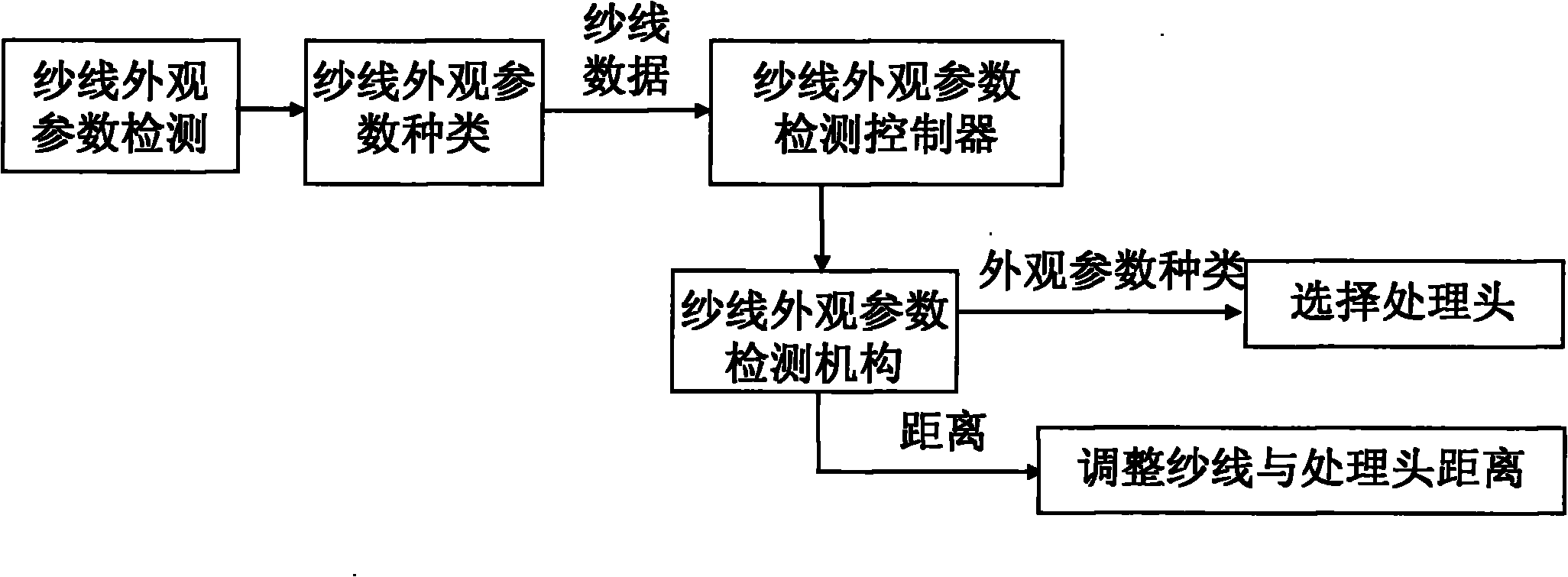

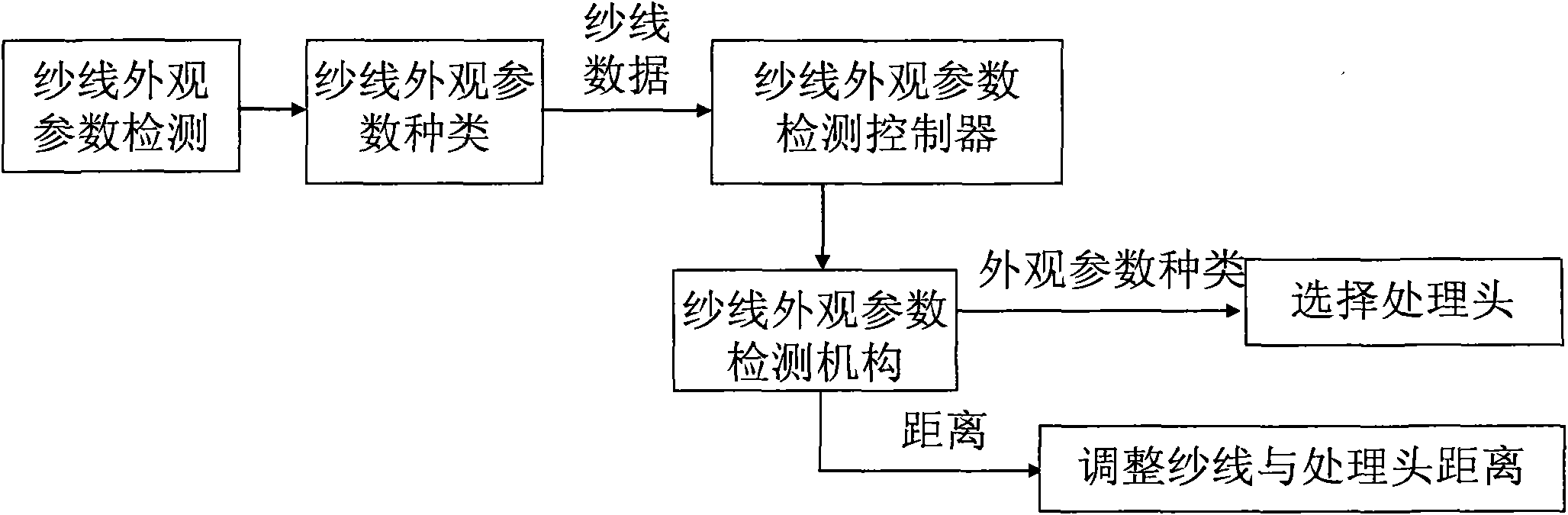

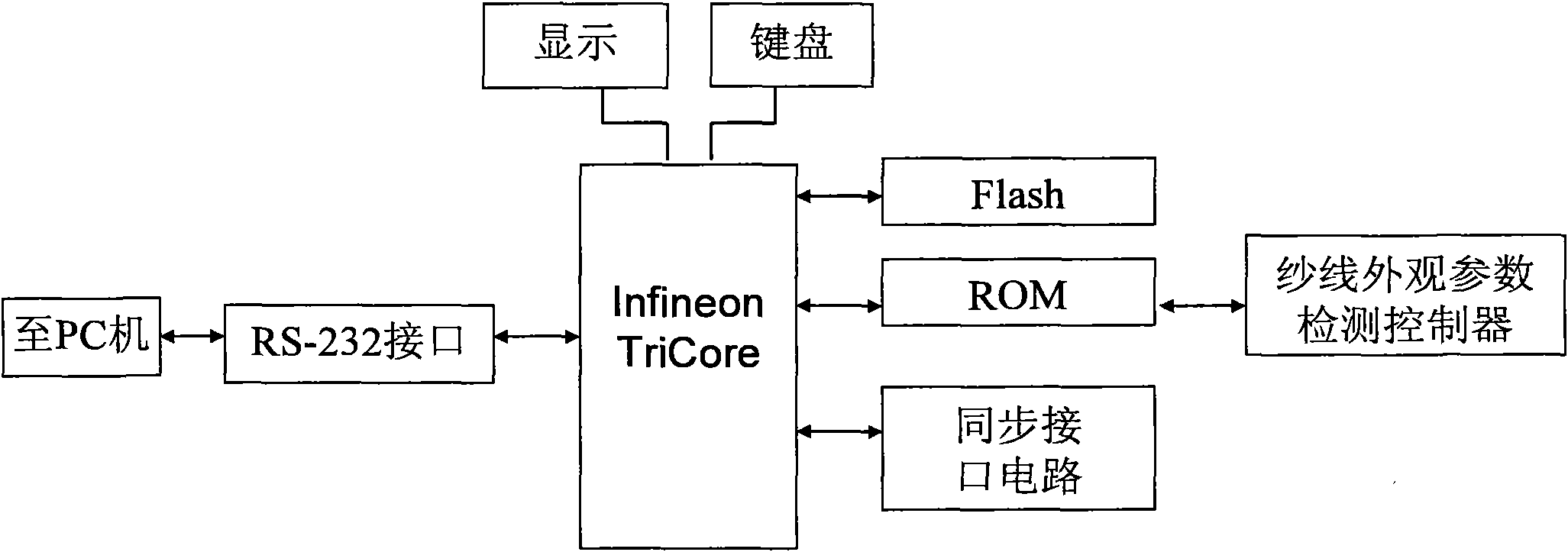

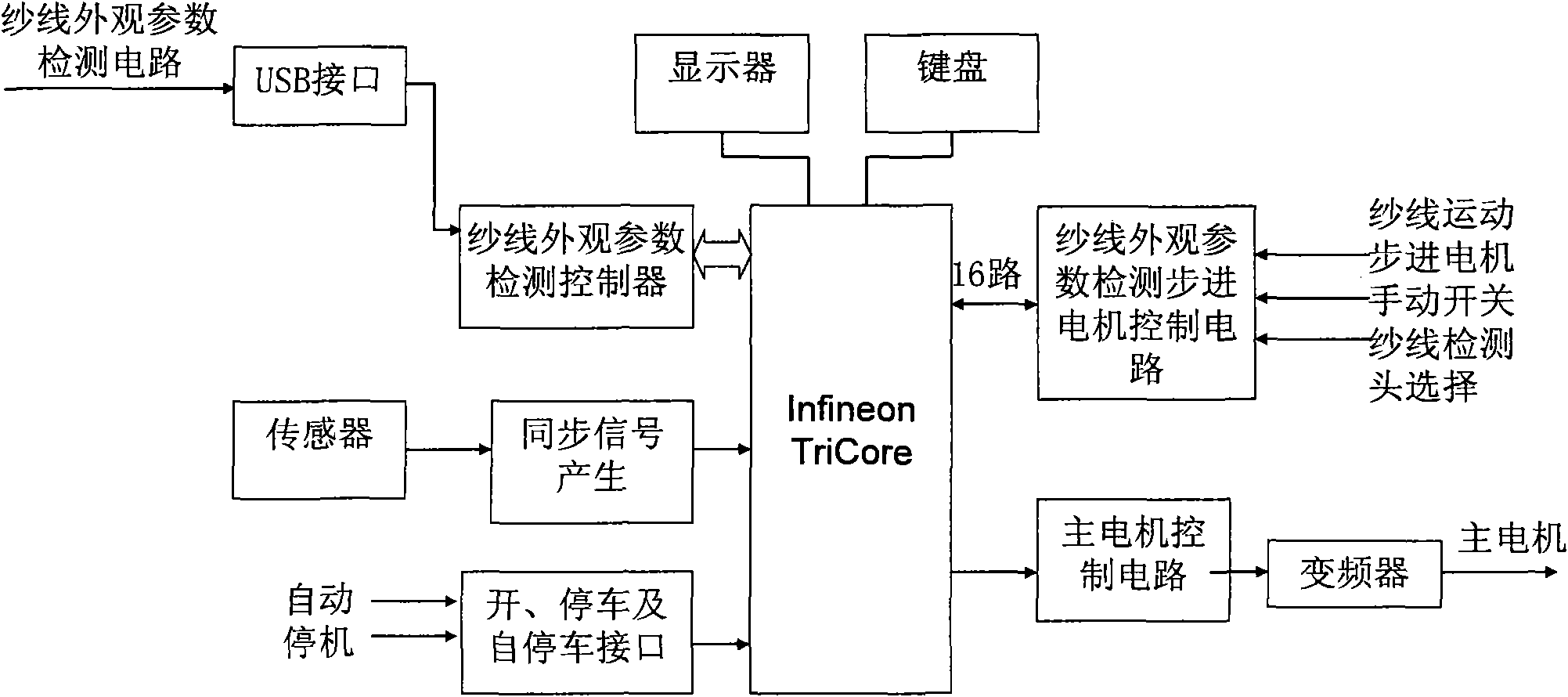

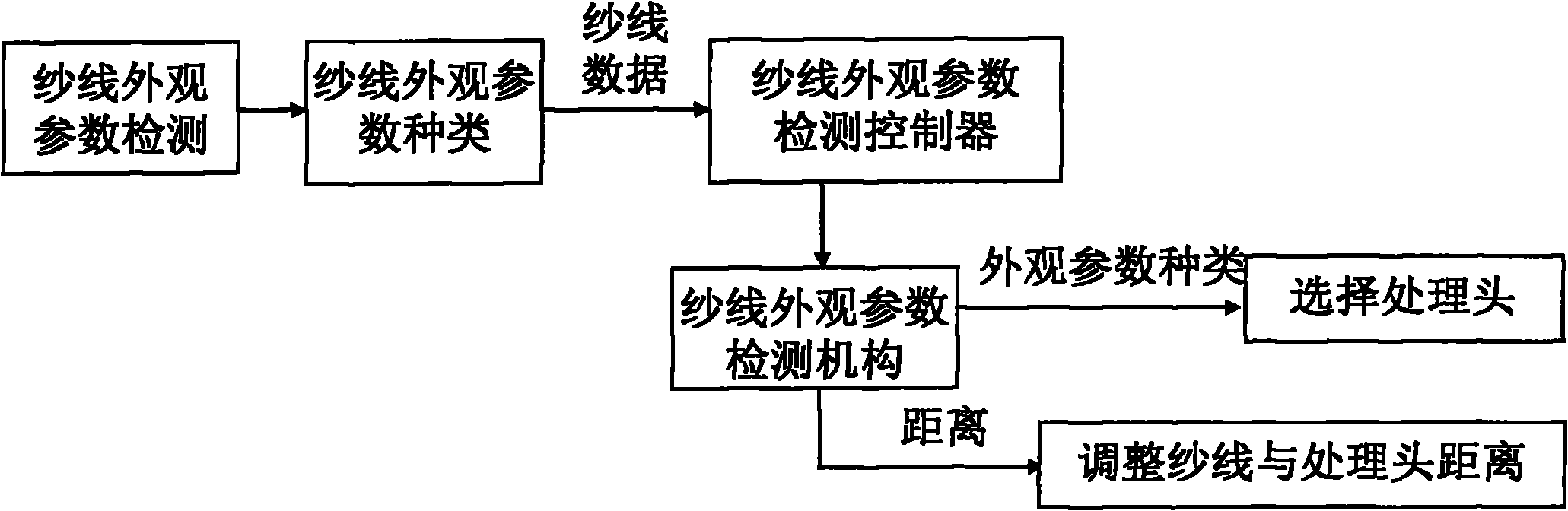

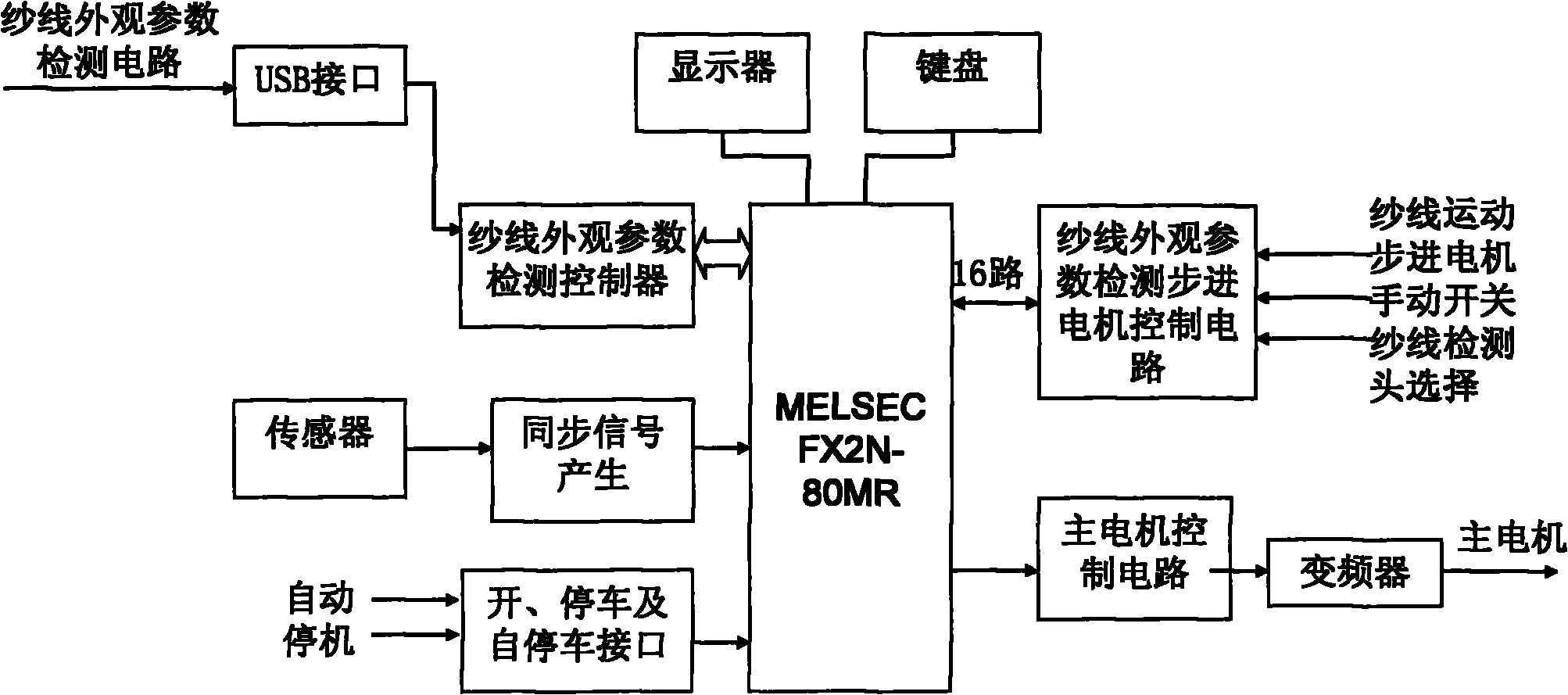

Special field programmable gate array (FPGA) controller for detecting appearance parameters of yarns

InactiveCN102023605AReal-time fully automatic controlProgramme control in sequence/logic controllersYarnSpecific detection

The invention discloses a special field programmable gate array (FPGA) controller for detecting the appearance parameters of yarns, which belongs to the technical field of new textile machines, and aims to solve the technical problem that because the types of the appearance parameters of yarns are various, and in the process of detecting the appearance parameters of different yarns, the movement velocities of the yarns, the types of detecting heads and the distances between the detecting heads and the yarns are all different, a simple and unique software processing method obviously can not satisfy the real-time control requirements for the detection on the appearance parameters of the yarns through a specific detection process selected according to the type of the appearance parameters of the yarns required to be detected in the process of detecting the appearance parameters of yarns. For solving the technical problem, in the invention, an FPGA controller system is used as the core of a control system for reading in the types and relevant characteristics of the appearance parameters of the yarns, and controlling the subsequent processing flow of the detection on the appearance parameters of yarns so as to satisfy the real-time control requirements for the detection on the appearance parameters of the yarns, thereby completing the processing flow of the detection on the appearance parameters of yarns.

Owner:JIANGNAN UNIV

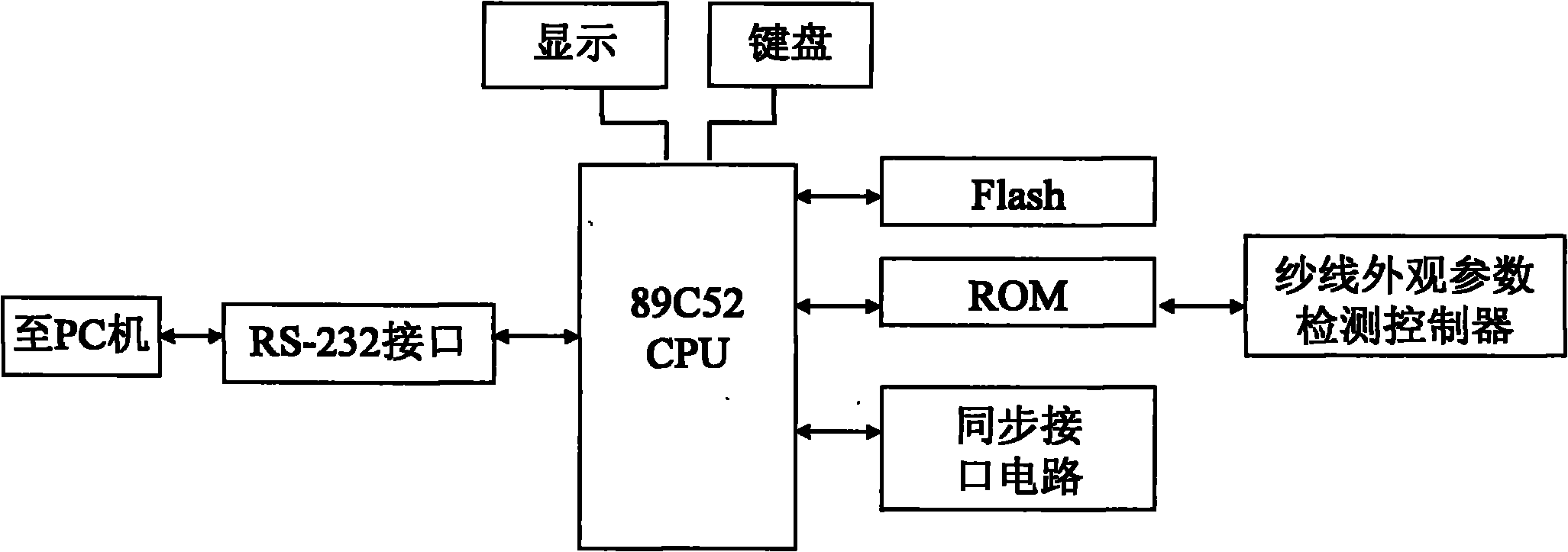

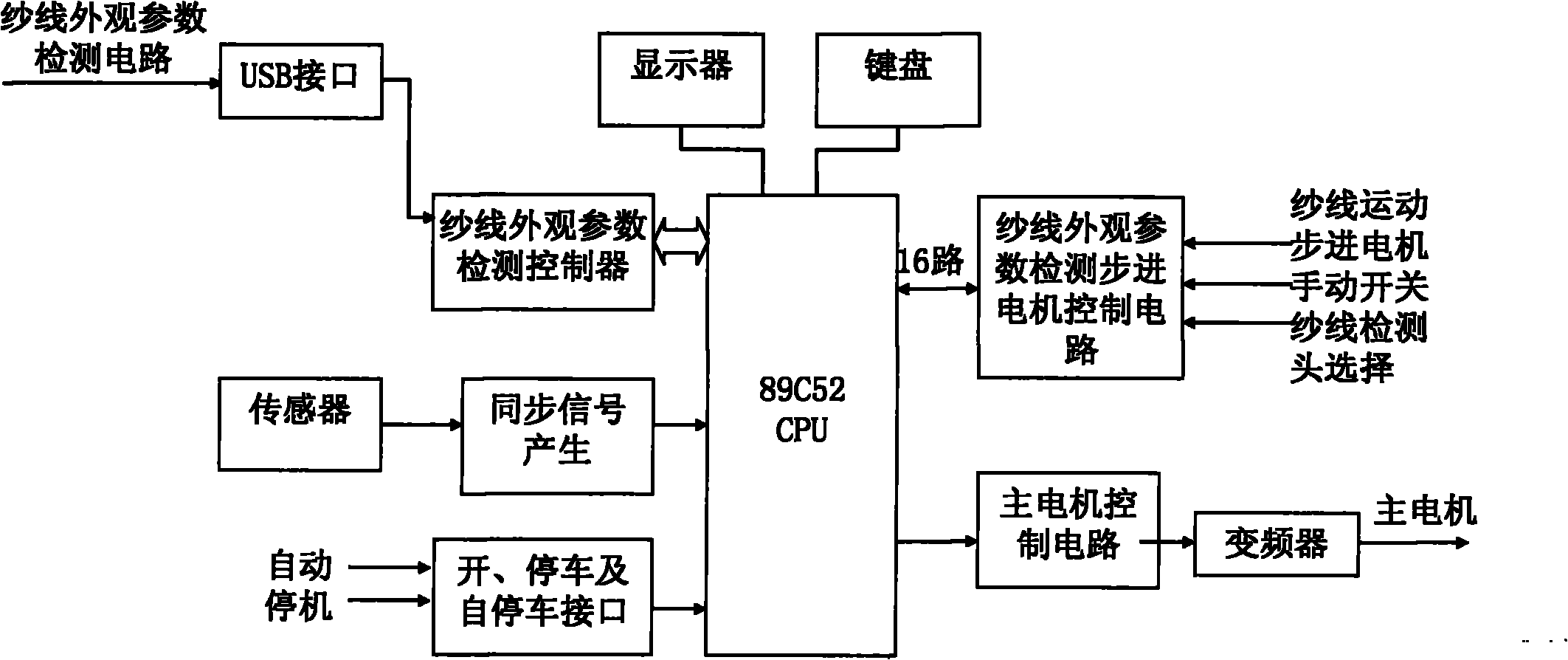

Special SCM (Single Chip Microcomputer) controller for detecting yarn appearance parameters

InactiveCN102109830AReal-time fully automatic controlEfficient fully automatic controlProgramme controlComputer controlRelevant featureYarn

The invention provides a special SCM (Single Chip Microcomputer) controller for detecting yarn appearance parameters, belonging to the field of a novel textile machine. As the yarn appearance parameters have many type, the yarn movement speeds, the detection head types and the distance between the detection head and the yarns are different when the different yarn appearance parameters are detected, a special detection flow is selected according to the types of the to-be-detected yarn appearance parameters when the different yarn appearance parameters are detected; a simple and unique software processing method obviously cannot meet real-time control demands of detecting the yarn appearance parameters. In order to solve the problem, the invention employs the single chip microcomputer (SCM) as a core of a control system, the SCM reads the types and the related features of the yarn appearance parameters, and controls the subsequent processing flows for detecting the yarn appearance parameters so as to meet the real-time control demands for processing the yarn appearance parameters, thereby finishing the processing flow for detecting the yarn appearance parameters.

Owner:JIANGNAN UNIV

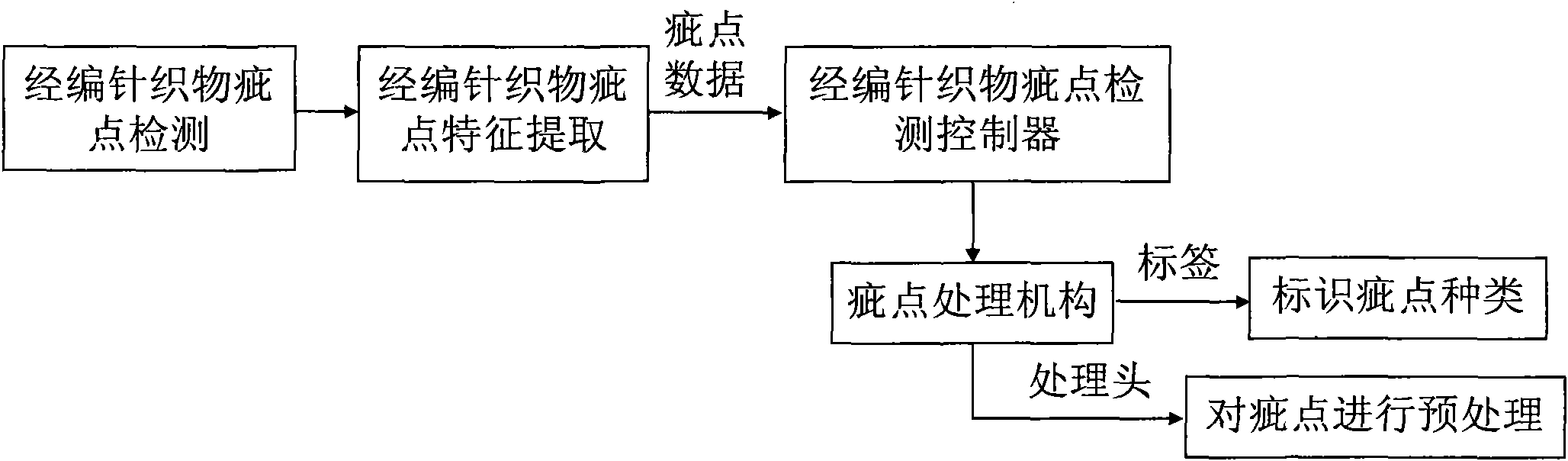

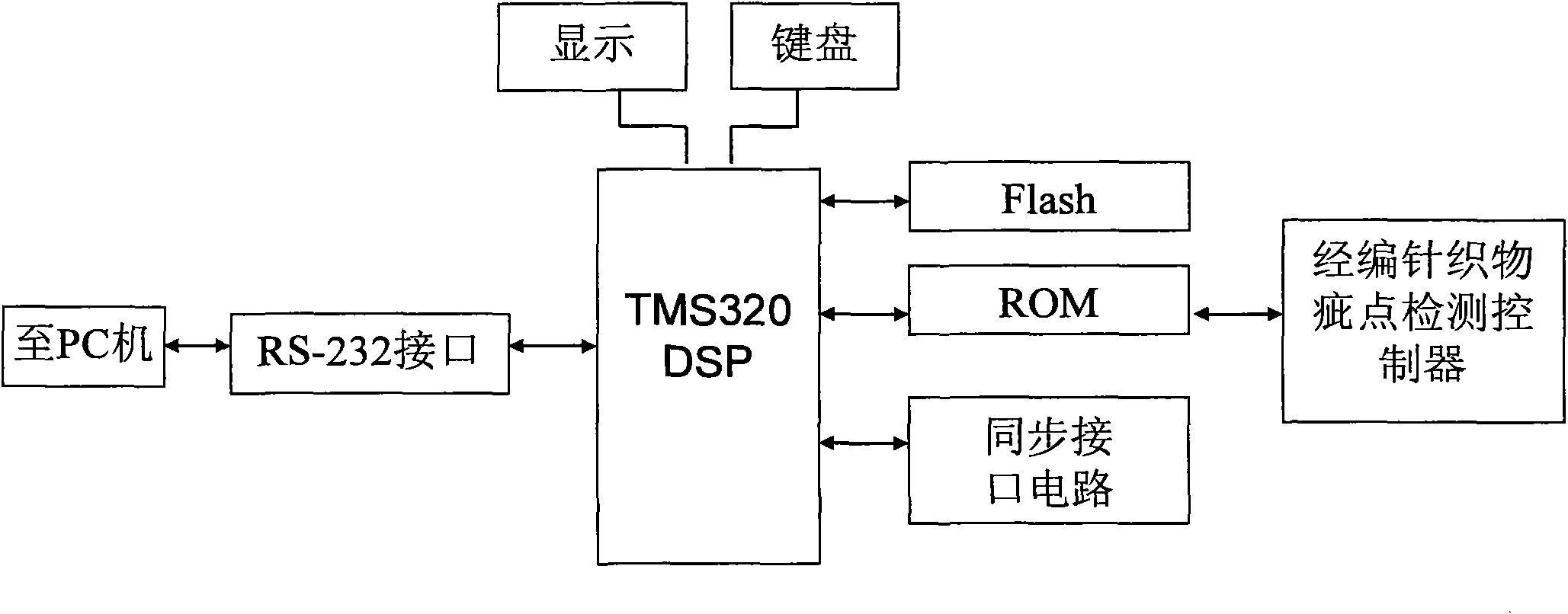

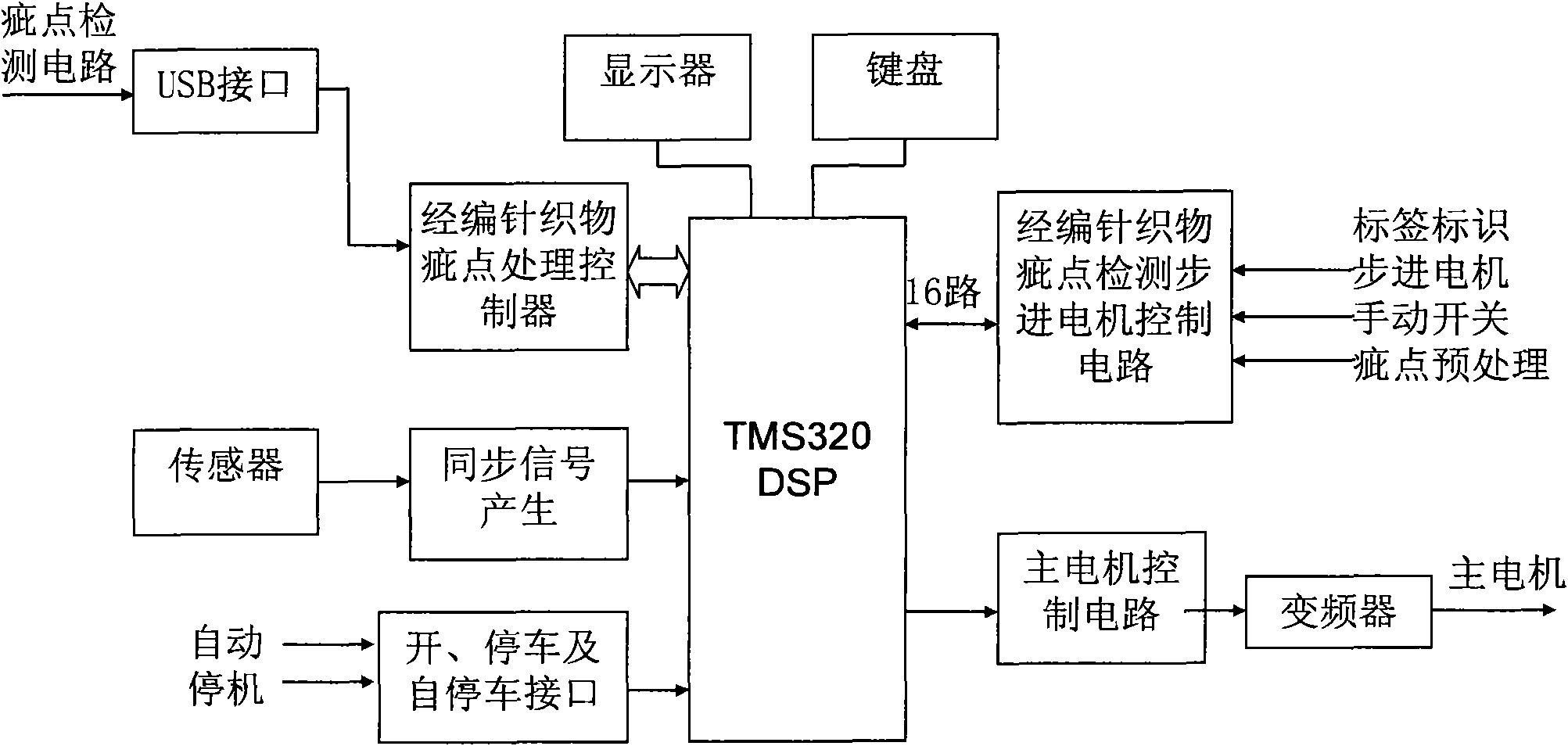

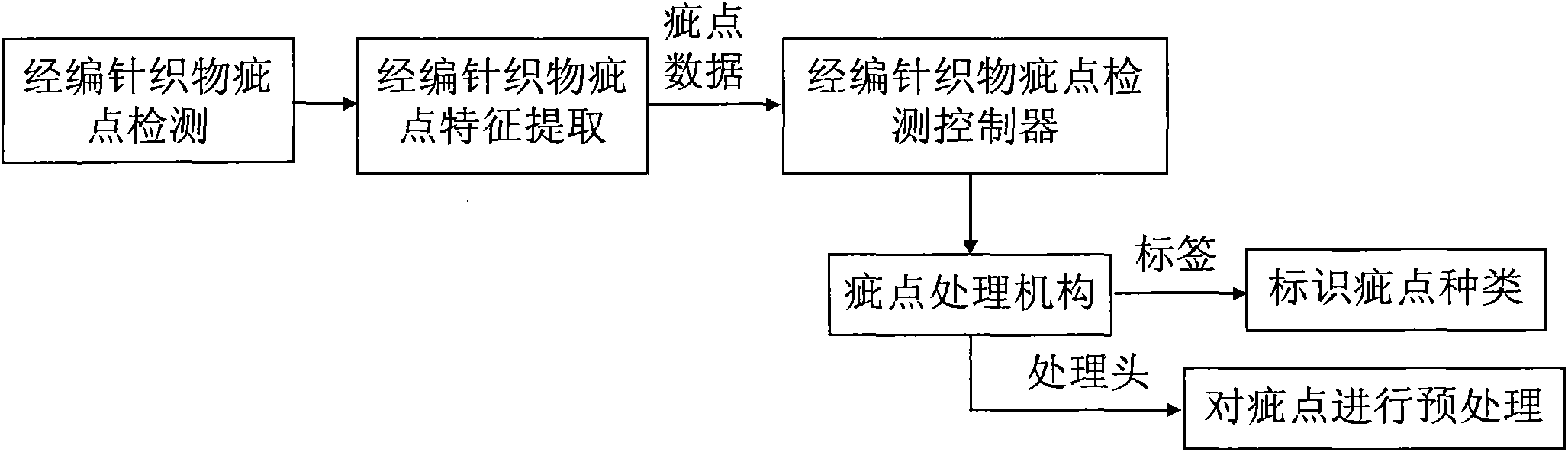

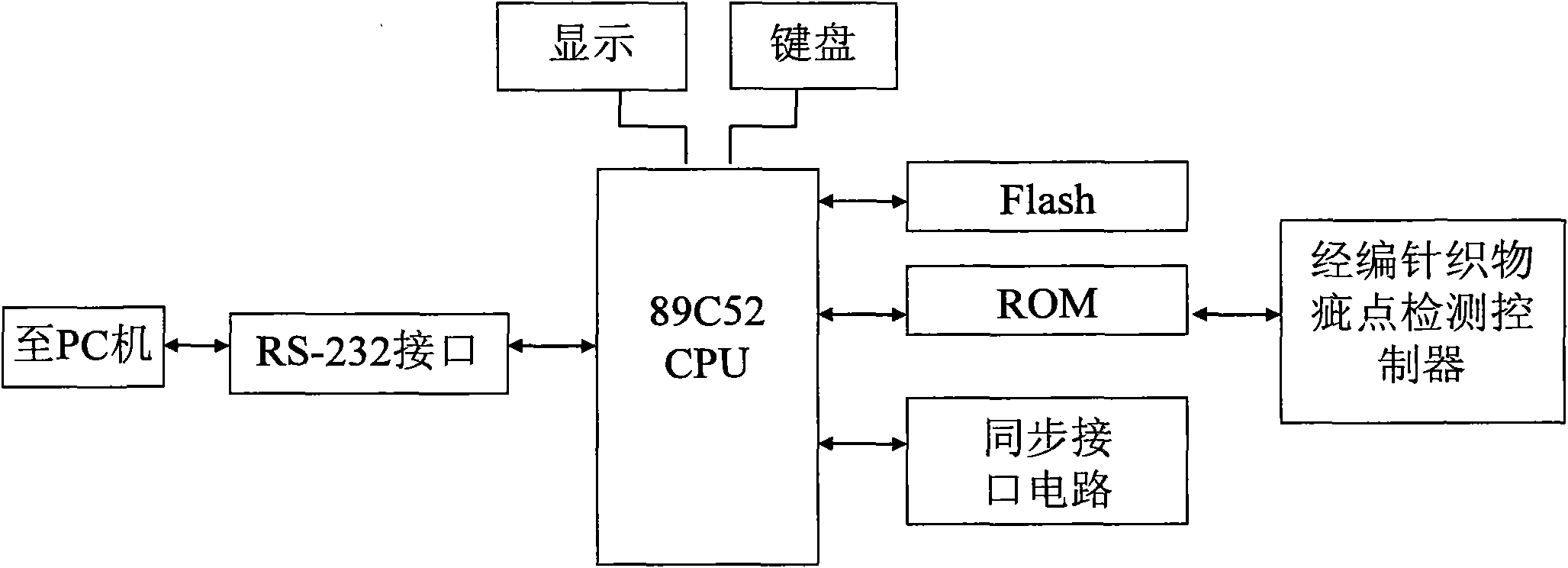

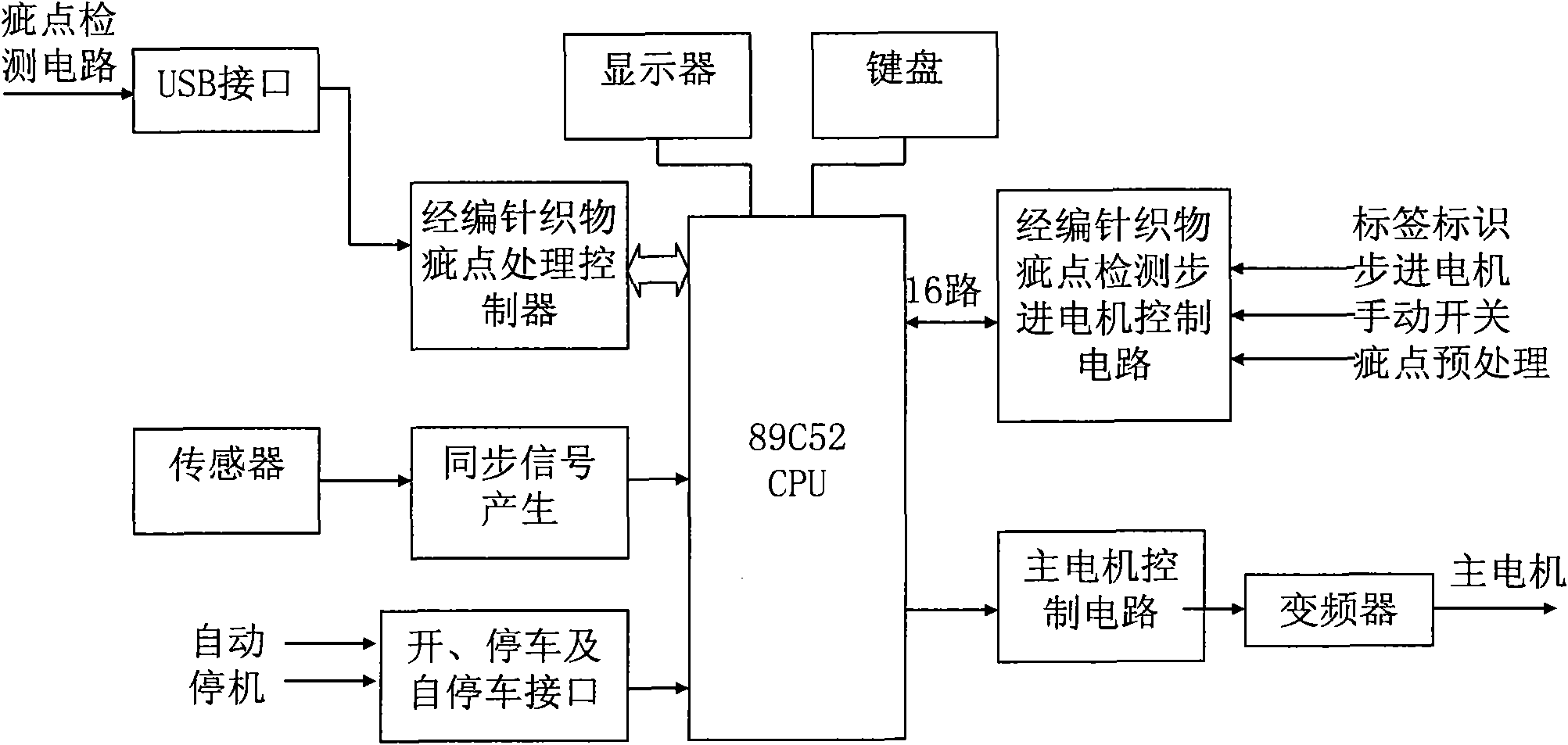

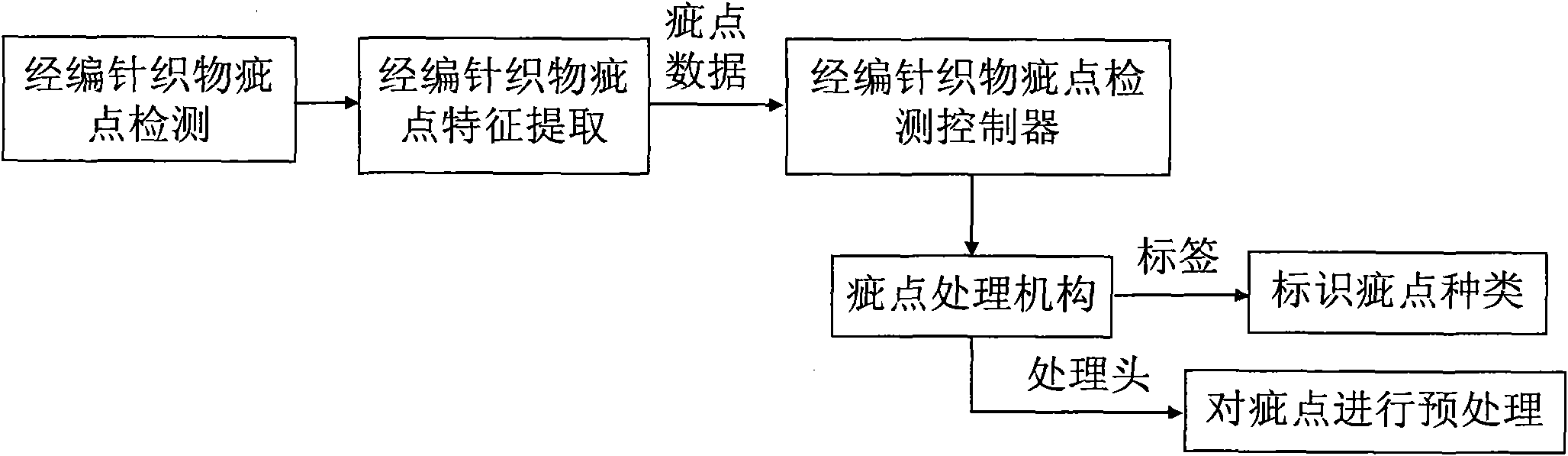

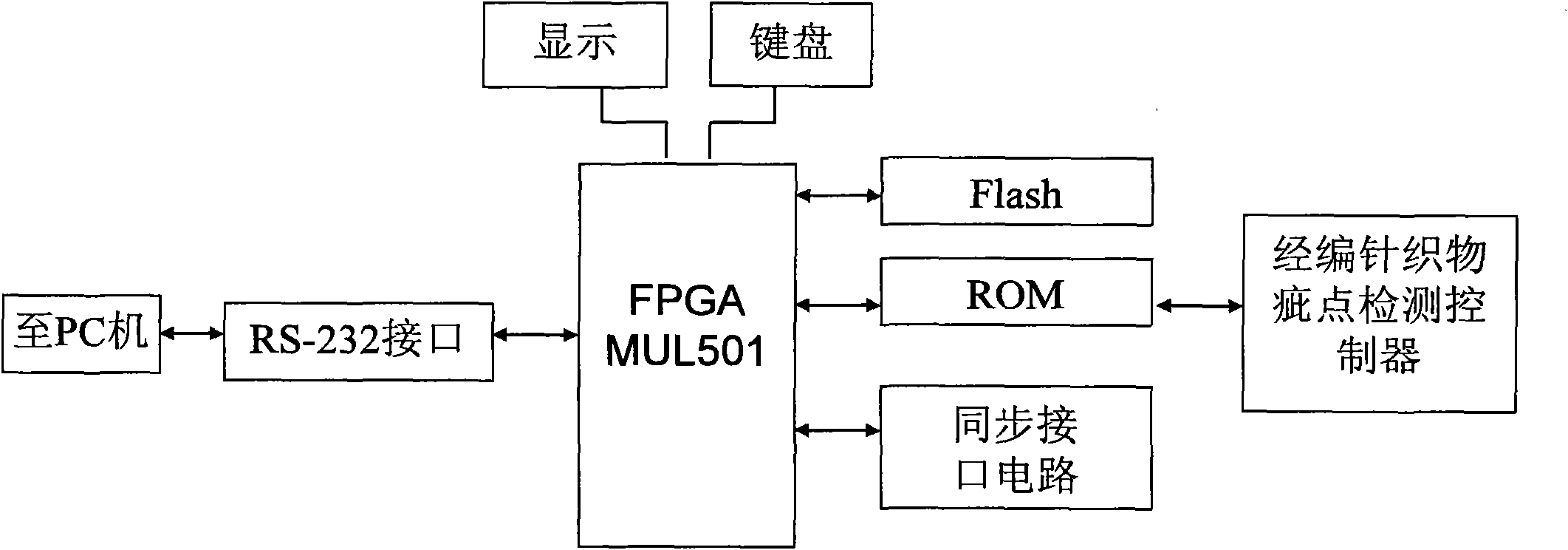

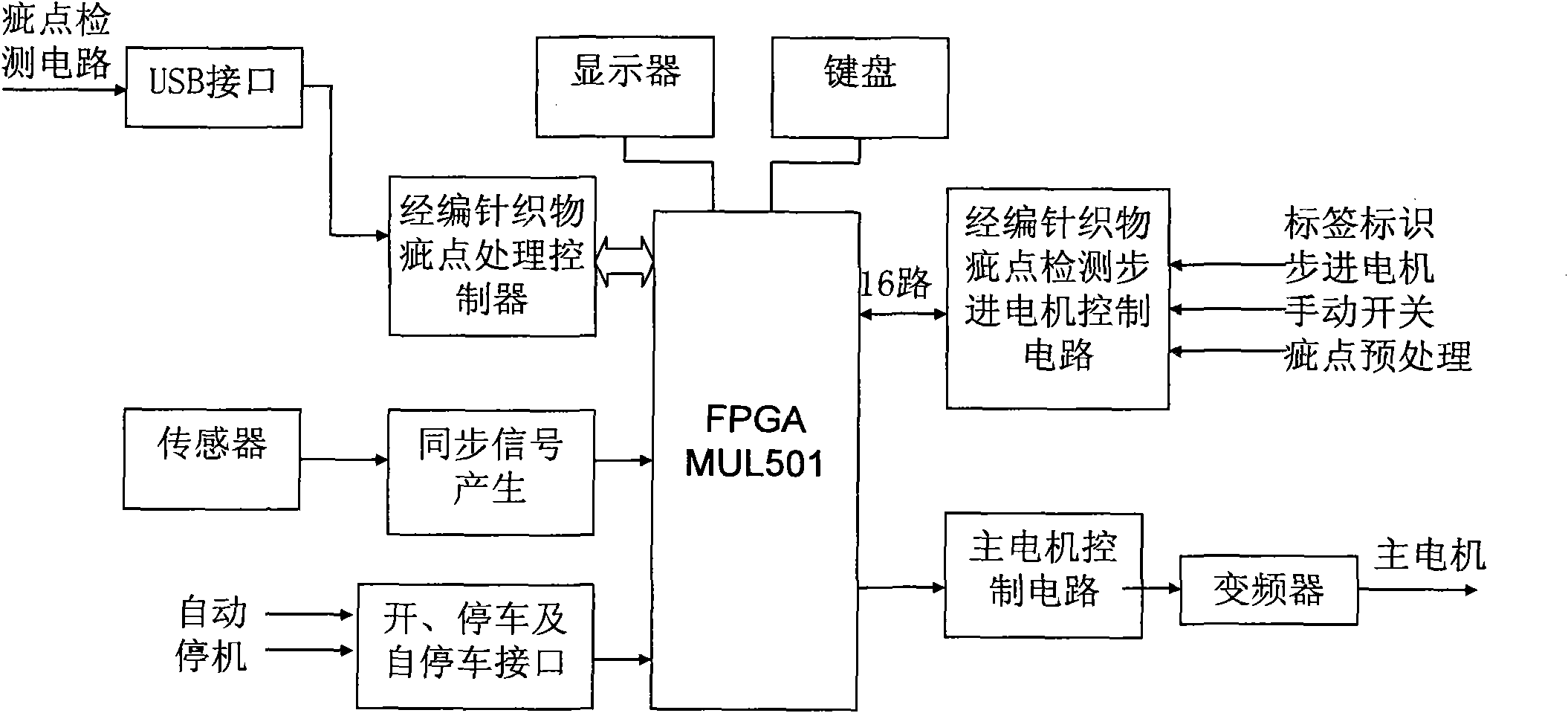

Digital signal processor (DSP) controller special for detecting defects of warp-knitted fabrics

InactiveCN102023596AReal-time fully automatic controlProgramme controlComputer controlControl systemEngineering

The invention provides a digital signal processor (DSP) controller special for detecting defects of warp-knitted fabrics, belonging to the field of novel textile machinery. The warp-knitted fabrics have the defects of wide varieties and complex detection algorithm, so the specific detect treatment flow is needed to be selected according to the varieties and relevant characteristics of the defects during defect detection. By adopting a simple single software treatment method, the real-time control requirement of defect detection can not be met obviously. In order to solve the technical problem, in the invention, a DSP is taken as the core of a control system and is used for reading the varieties and relevant characteristics of the defects and controlling the subsequent treatment flow of the defects of the warp-knitted fabrics so as to meet the real-time control requirement of defect detection treatment, thus completing the treatment flows of the defects of the warp-knitted fabrics.

Owner:JIANGNAN UNIV

SCM controller special for detecting defects of warp-knitted fabrics

InactiveCN102012676AReal-time fully automatic controlEfficient fully automatic controlProgramme control in sequence/logic controllersMicrocontrollerMicrocomputer

An SCM controller special for detecting defects of warp-knitted fabrics belongs to the field of novel textile machinery. The defects of warp-knitted fabrics are characterized by wide varieties,and detection algorithm is complexed, so the specific detect treatment flow needs to be selected according to the variety and relevant characteristics of the defects during defect detection. Adopting simple single software treatment method obviously can not meet the real-time control requirement of defect detection. In order to solve the technical problem, in the invention, a single-chip microcomputer (SCM) is taken as the core of a control system and is used for reading the variety and relevant characteristics of the defects and controlling the subsequent treatment flow of the defects of warp-knitted fabrics so as to meet the real-time control requirement of defect detection treatment, thus completing treatment flow of the defects of warp-knitted fabrics.

Owner:JIANGNAN UNIV

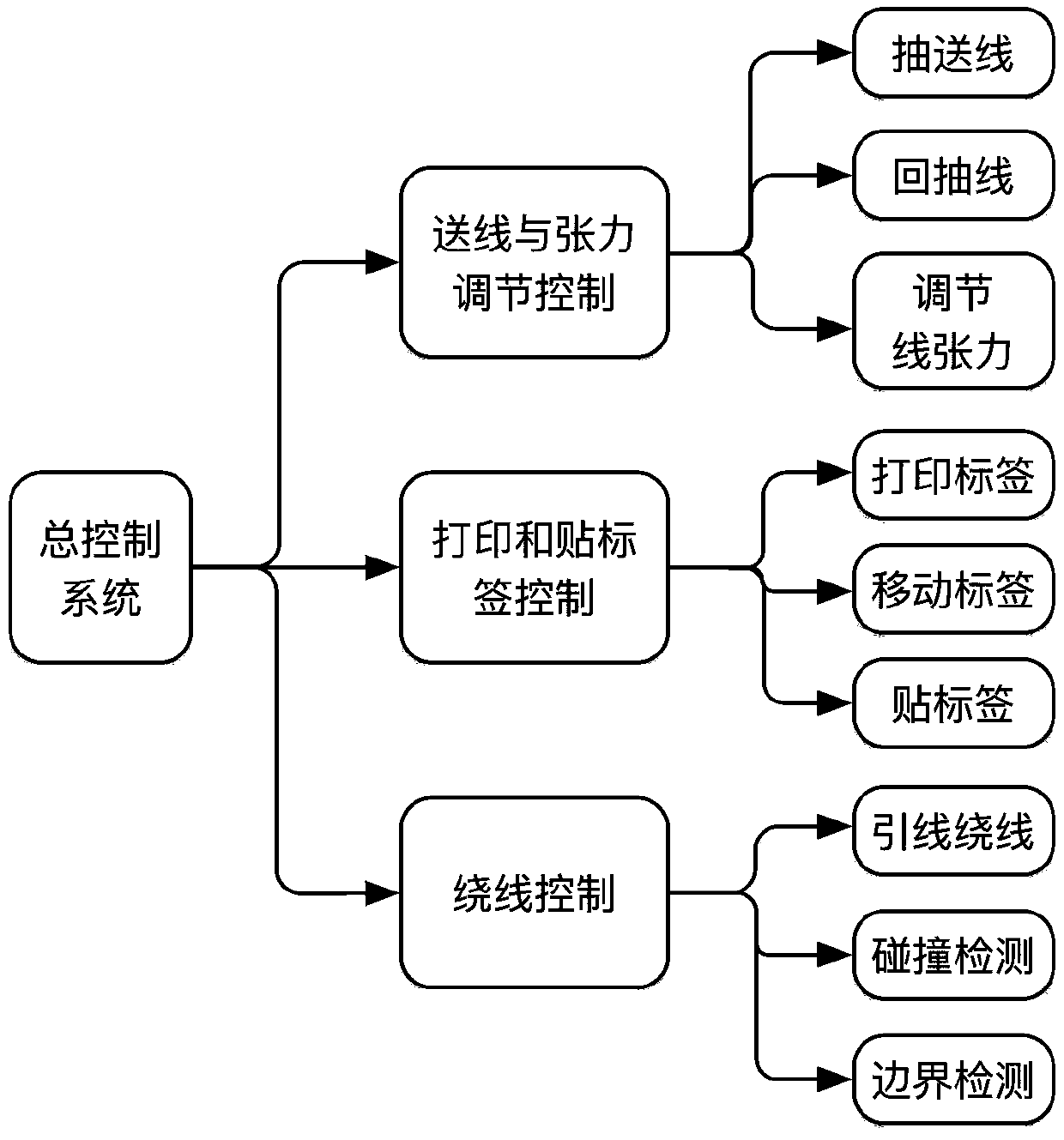

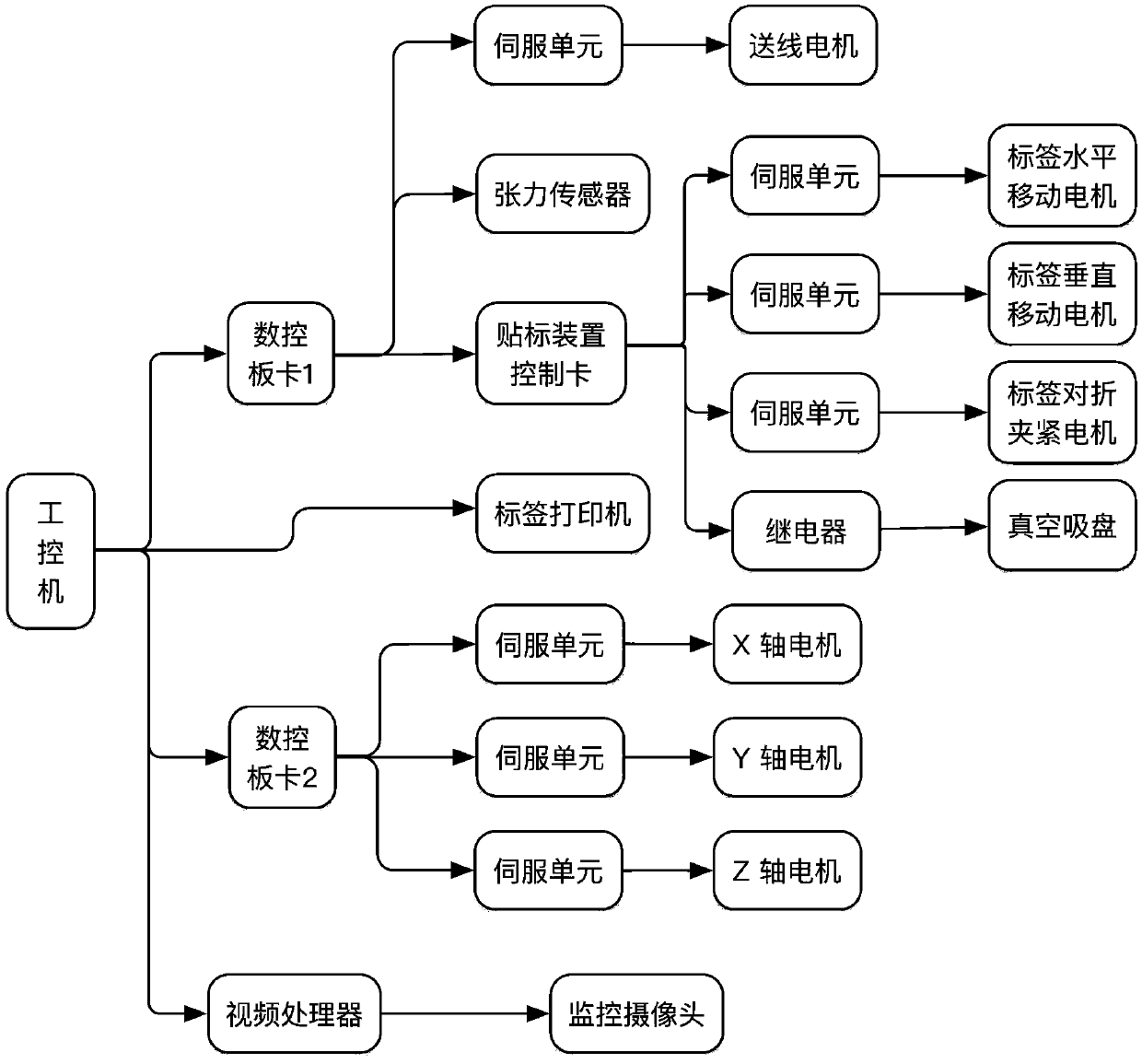

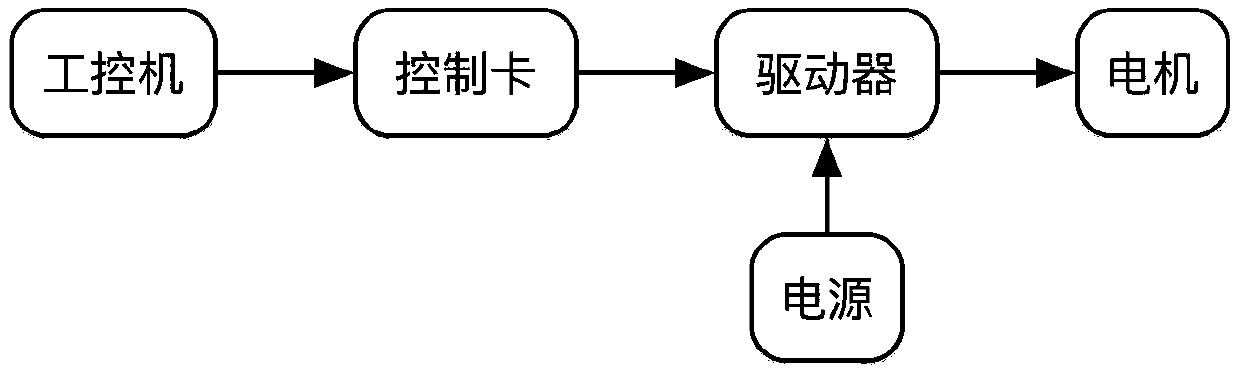

Automatic wiring machine based on winding form

InactiveCN109585093ASolving Integrated ControlSolve the automatic controlManufacturing wire harnessesProgramme total factory controlNumerical controlAutomatic control

The invention relates to an automatic wiring machine based on a winding form, which comprises an industrial personal computer, a wire feeding labeling and tension sensing unit, a label printing unit,a wiring unit and a video processing unit, and is characterized in that the input ends of the wire feeding labeling and tension sensing unit, the label printing unit, the wiring unit and the video processing unit are respectively connected with the output end of the industrial personal computer; The wire feeding, labeling and tension sensing unit comprises a numerical control board card, a wire feeding motor unit, a tension sensing unit and a labeling control unit. The label printing unit comprises label printing; The wiring unit comprises a numerical control board card and a winding motion platform. The video processing unit comprises a video processor and a monitoring camera. The full-automatic wire harness labeling machine has the advantages that integrated control, wire tension automatic adjustment control and real-time online labeling device and wire winding device full-automatic control of an automatic wire arrangement machine based on a wire winding mode are achieved at the sametime, the yield of wire harness products is effectively increased, the labor intensity is reduced, and the production period and the technical requirements of operators are reduced.

Owner:航天极创物联网研究院(南京)有限公司

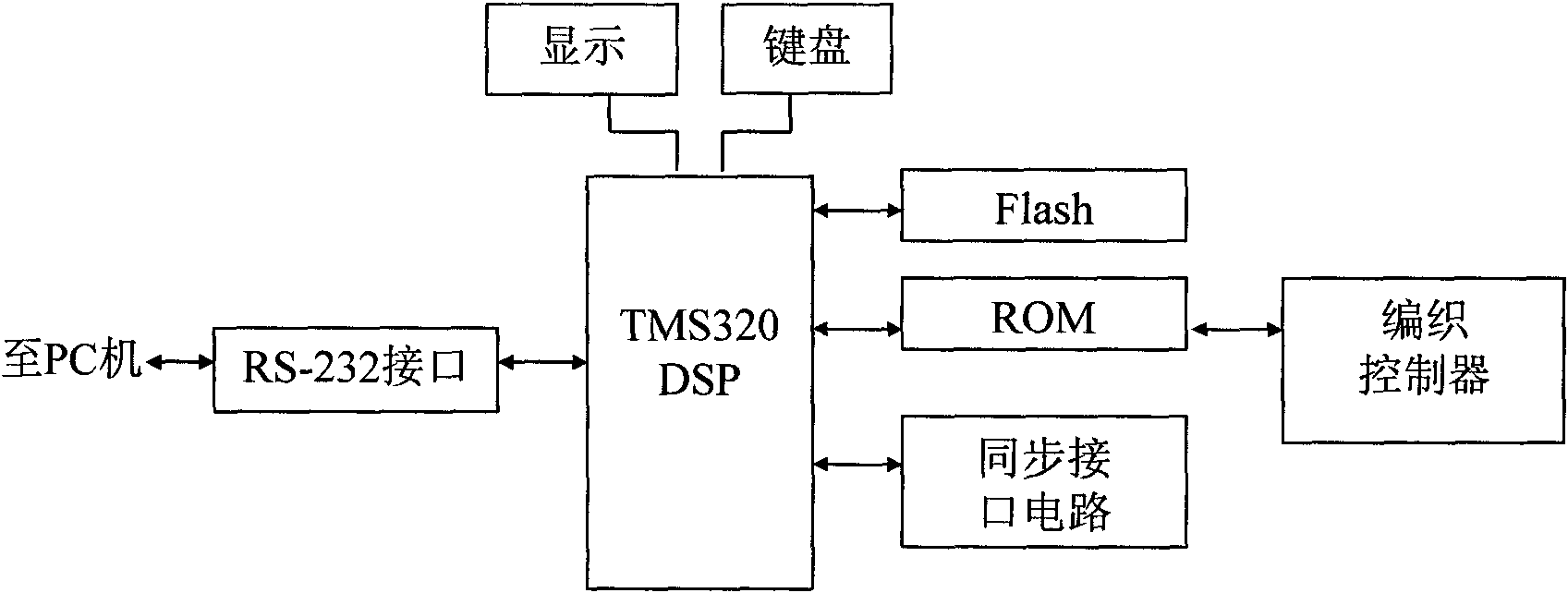

Special ARM controller for jacquard fur knitting

InactiveCN101724971AReal-time fully automatic controlWeft knittingTotal factory controlEmbedded systemDesign pattern

The invention relates to a special ARM embedded system controller for jacquard fur knitting, which belongs to the field of novel textile machinery. Because the product of a jacquard fur knitting machine is provided with multiple patterns, when wool tops are fed, the color and the feeding quantity of the wool tops need to be automatically selected according to the designed patterns, and obviously, the process requirement can not be satisfied by adopting a manual method. In order to solve the technical problem, an ARM embedded system is used as the core of a control system, the designed patterns are read-in through the ARM embedded system, and the action of a knitting needle is controlled according to the data of the patterns so as to hook up the wool tops in various colors to satisfy the requirement of pattern design and finish the production of jacquard fur.

Owner:JIANGNAN UNIV

SOC controller special for detecting yarn appearance parameters

InactiveCN102023585AReal-time fully automatic controlProgramme control in sequence/logic controllersYarnControl system

The invention discloses a system on a chip (SOC) controller special for detecting yarn appearance parameters and belongs to the field of novel textile machinery. The types of the yarn appearance parameters are multiple, and the yarn movement velocity, the types of detecting heads and the distance between the detecting head and the yarn are different when different yarn appearance parameters are detected, so when the yarn appearance parameters are detected, a specific detecting flow is selected according to the types of the yarn appearance parameters need detecting, and the real-time control requirement of the yarn appearance parameters cannot be met by a simple and unique software processing method obviously. In order to solve the problem, the SOC controller takes an SOC controller system as a core of a control system, the SOC controller reads in the yarn appearance parameters and related characteristics, and the SOC controller system controls the subsequent processing flow of detecting the yarn appearance parameters to meet the real-time control requirement of processing of the yarn appearance parameters and complete the processing flow of detecting the yarn appearance parameters.

Owner:JIANGNAN UNIV

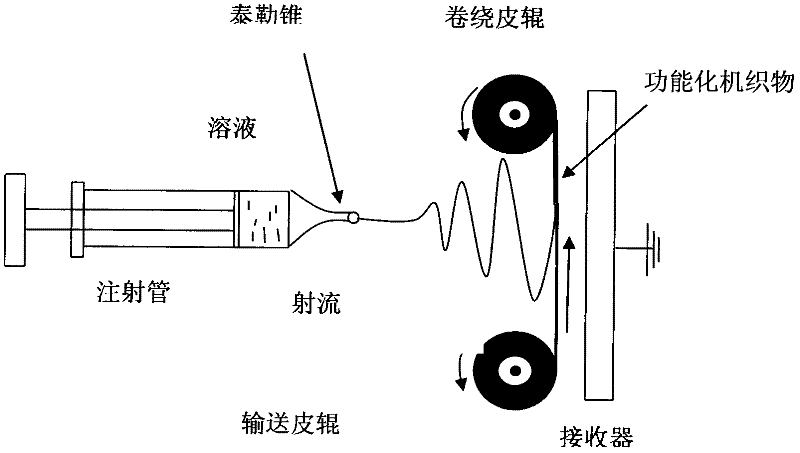

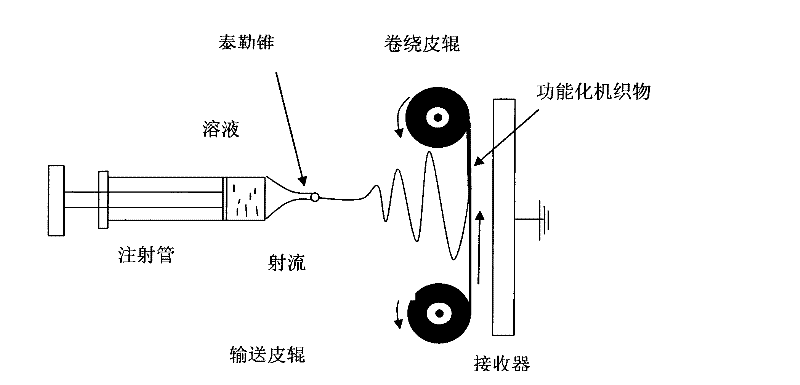

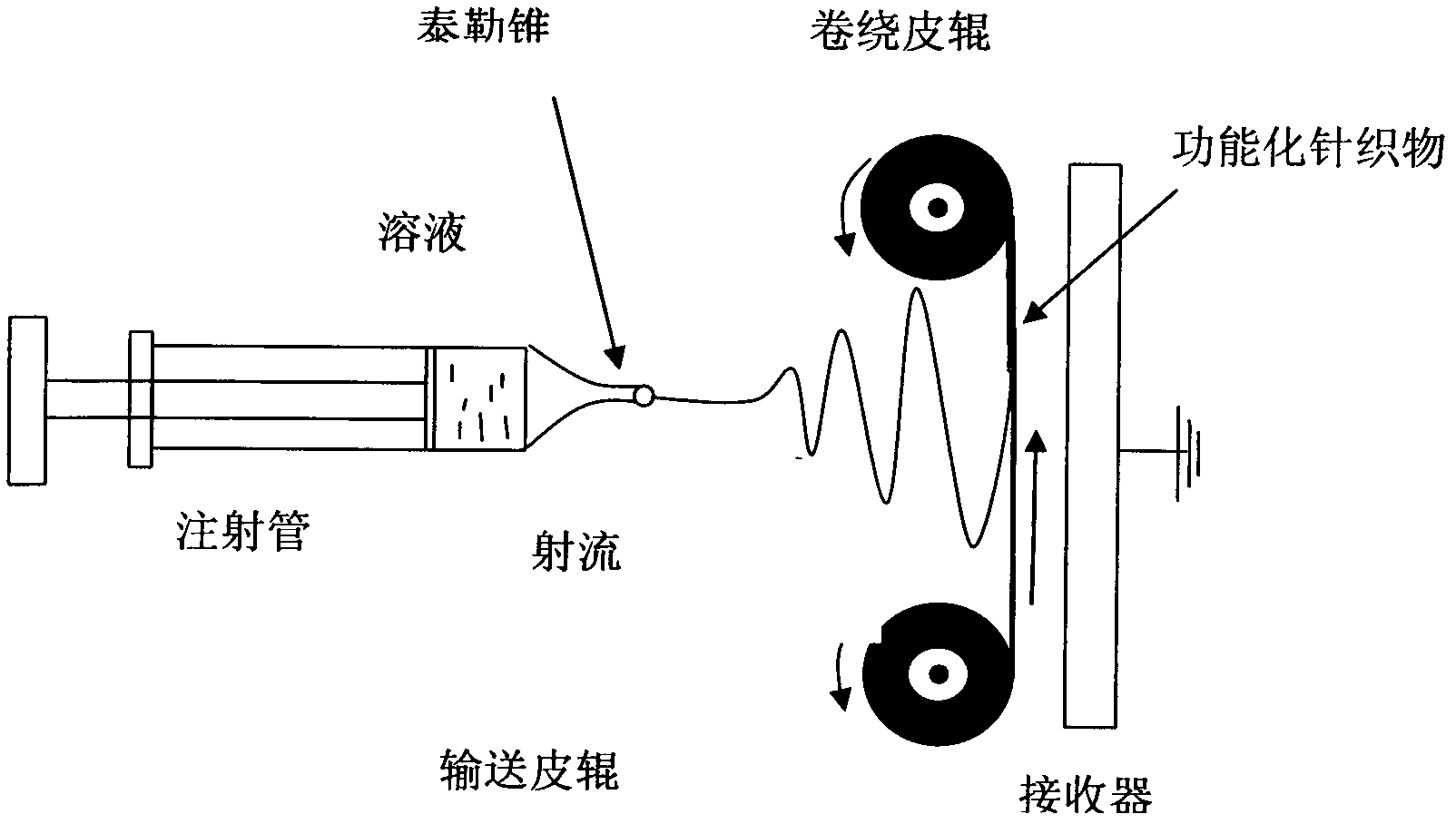

Special functionalized knitted fabric equipment for nanofiber surface coating

InactiveCN102520638AOvercome strengthOvercoming productivityProgramme controlComputer controlControl systemNanofiber

The invention discloses a special CPLD (Complex Programmable Logic Device) controller for functionalized knitted fabric equipment of nanofiber surface coating, belonging to the field of novel textile machinery. The functionalized knitted fabric equipment of the nanofiber surface coating includes various models, in the processing procedure of the equipment, different technologies need to be regulated, and the regulation is divided into a single regulation mode, a continuous regulation mode and the like, so that the feeding amount and the feeding speed need to be selected automatically according to the technological requirement, and a manual method obviously cannot meet the technical requirement. For solving the technical problem, the CPLD is used as the core for controlling the system in the invention, and the CPLD finishes the action of reading the designed feeding amount and the feeding rate to produce different coating products, thereby meeting the requirement on design of the functionalized knitted fabric and finishing the production of the knitted fabrics having necessary functions.

Owner:JIANGNAN UNIV

Special functionalized woven fabric equipment for nanofiber surface coating

InactiveCN102520639AOvercome strengthOvercoming productivityProgramme controlComputer controlControl systemNanofiber

The invention discloses a special CPLD (Complex Programmable Logic Device) controller for functionalized woven fabric equipment of nanofiber surface coating, belonging to the field of novel textile machinery. The functionalized woven fabric equipment of the nanofiber surface coating includes various models, in the processing procedure of the equipment, different technologies need to be regulated, and the regulation is divided into a single regulation mode, a continuous regulation mode and the like, so that the feeding amount and the feeding speed need to be selected automatically according to the technological requirement, and a manual method obviously cannot meet the technological requirement. For solving the technical problem, the CPLD is used as the core of the control system in the invention, and the CPLD finishes the action of reading the designed feeding amount and the feeding rate to produce different coating products, thereby meeting the requirement on design of the functionalized woven fabric and finishing the production of the woven fabrics having necessary functions.

Owner:JIANGNAN UNIV

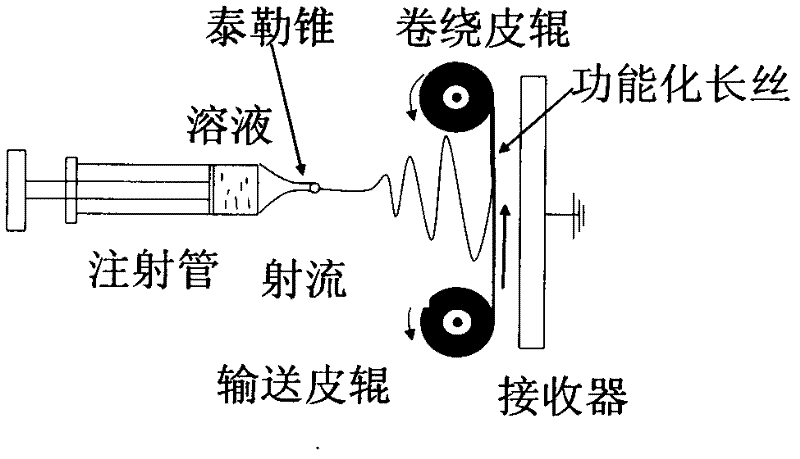

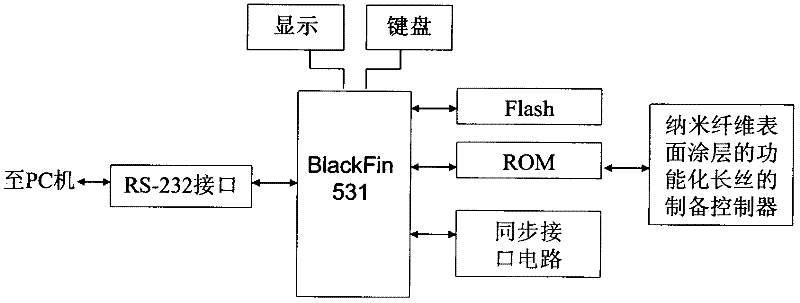

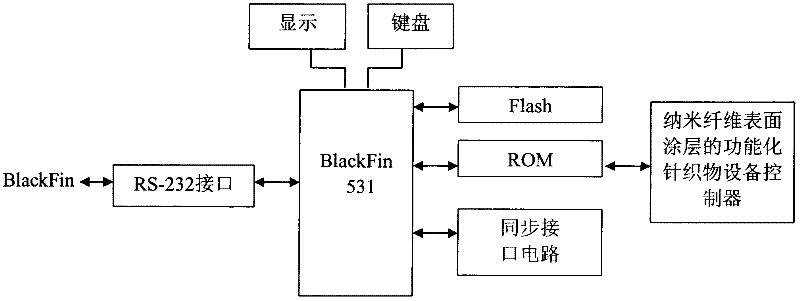

Special BlackFin controller for nanofiber surface coating functionalized filament equipment

InactiveCN102520633AOvercome strengthOvercoming productivityProgramme controlComputer controlFiberControl system

The invention discloses a special BlackFin controller for equipment of functionalized filaments of nanofiber surface coating, belonging to the field of novel textile machinery. The equipment of the functionalized filaments of the nanofiber surface coating includes various models, in the processing procedure of the equipment, different technologies need to be regulated, and the regulation is divided into a single regulation mode, a continuous regulation mode and the like, so that the feeding amount and the feeding speed need to be selected automatically according to the technological requirement, and a manual method obviously cannot meet the technical requirement. For solving the technical problem, the BlackFin is used as the core for controlling the system in the invention, and the BlackFin finishes the action of reading the designed feeding amount and the feeding rate to produce different coating products, thereby meeting the requirement on design of the functionalized filaments and finishing the production of the filaments having necessary functions.

Owner:JIANGNAN UNIV

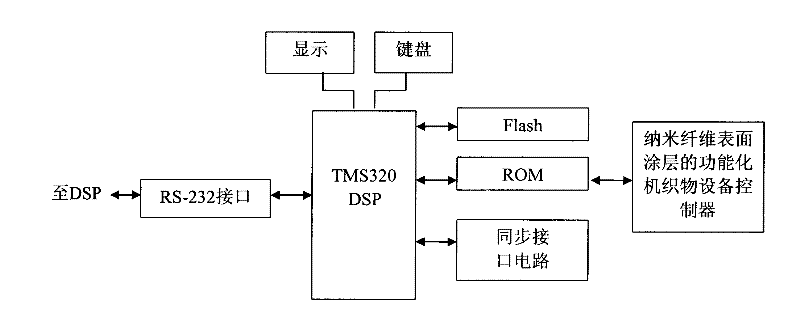

Full-automatic nanofiber surface coating functionalized woven fabric equipment

InactiveCN102520649AOvercome strengthOvercoming productivityProgramme controlComputer controlControl systemNanofiber

The invention discloses a special DSP (Digital Signal Processor) controller for functionalized woven fabric equipment of nanofiber surface coating, belonging to the field of novel textile machinery. The functionalized woven fabric equipment of the nanofiber surface coating includes various models, in the processing procedure of the equipment, different technologies need to be regulated, and the regulation is divided into a single regulation mode, a continuous regulation mode and the like, so that the feeding amount and the feeding speed need to be selected automatically according to the technological requirement, and a manual method obviously cannot meet the technical requirement. For solving the technical problem, the DSP is used as the core for controlling the system in the invention, and the DSP finishes the action of reading the designed feeding amount and the feeding rate to produce different coating products, thereby meeting the requirement on design of the functionalized woven fabric and finishing the production of the woven fabrics having necessary functions.

Owner:JIANGNAN UNIV

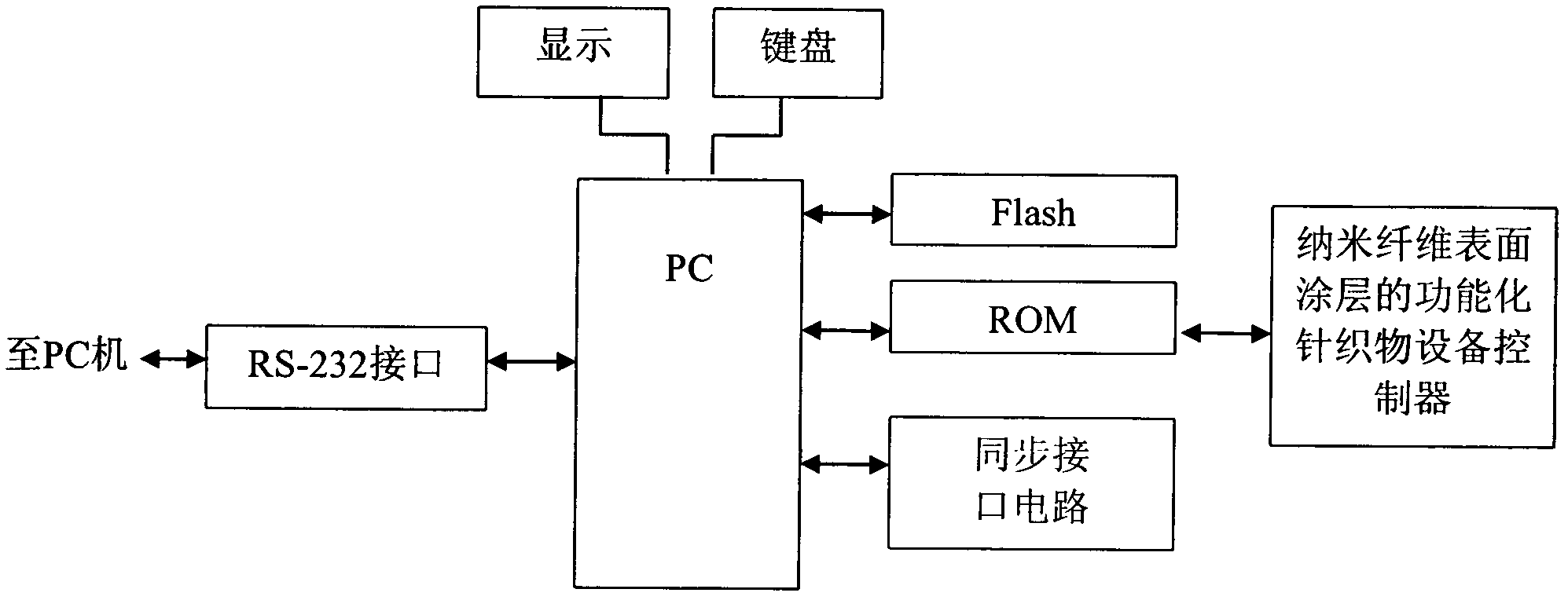

Intelligent functional knitted fabric equipment with nanofiber surface coatings

InactiveCN102495572AOvercome strengthOvercoming productivityProgramme controlComputer controlFiberControl system

The invention provides a special PC (personal computer) controller for functional knitted fabric equipment with nanofiber surface coatings, belonging to the field of novel textile machinery. The functional knitted fabric equipment with nanofiber surface coatings has various types, different processes need to be adjusted in the processing course and the adjustment modes are divided into single adjustment and continuous adjustment, so the feed quantity and feeding speed need to be automatically selected according to the process requirements, and obviously, the manual method can not meet the process requirements. In order to solve the technical problem, in the invention, a PC is taken as the core of a control system and is used for reading the designed actions of the feed quantity and feeding speed, thus manufacturing different coated products to meet the requirements of functional knitted fabric design and further completing production of the knitted fabrics with essential functions.

Owner:JIANGNAN UNIV

Nanofiber surface coating functional filament equipment special ARM controller

InactiveCN102520645AOvercoming low strengthEasy to controlProgramme controlComputer controlMachining processEngineering

A preparation special-purpose ARM controller of a functional filament of nanofiber surface coating belongs to the novel textile machinery field. Since preparation of the functional filament of the nanofiber surface coating has a plurality of models, different technology is needed to be adjusted in a processing process, adjustment modes comprise single adjustment, continuous adjustment and the like, thus it is needed to automatically select feeding amount and feeding speed according to a technology requirement, and employing a manual method obviously can not satisfy the technology requirement. In order to solve the technical problem, according to the invention, an ARM is taken as a core of a control system, through a motion that the ARM reads designed feeding amount and feeding speed, different coating products are made so as to satisfy a requirement of functional filament design, and the production of a functional filament is completed.

Owner:JIANGNAN UNIV

Special FPGA controller for nanofiber surface coating functionalized filament equipment

InactiveCN102520662AOvercome strengthOvercoming productivityProgramme control in sequence/logic controllersFiberControl system

The invention discloses a special FPGA (Field Programmable Gate Array) for equipment of functionalized filaments of nanofiber surface coating, belonging to the field of novel textile machinery. The equipment of the functionalized filaments of the nanofiber surface coating includes various models, in the processing procedure of the equipment, different technologies need to be regulated, and the regulation is divided into a single regulation mode, a continuous regulation mode and the like, so that the feeding amount and the feeding speed need to be selected automatically according to the technological requirement, and a manual method obviously cannot meet the technical requirement. For solving the technical problem, the FPGA is used as the core for controlling the system in the invention, and the FPGA finishes the action of reading the designed feeding amount and the feeding rate to produce different coating products, thereby meeting the requirement on design of the functionalized filaments and finishing the production of the filaments having necessary functions.

Owner:JIANGNAN UNIV

Special SCM (Single Chip Machine) controller for detecting defects of woven fabric

InactiveCN102096380ARealize fully automatic controlReal-time fully automatic controlProgramme control in sequence/logic controllersMicrocontrollerControl system

The invention relates to a special SCM (Single Chip Machine) controller for detecting defects of a woven fabric, which belongs to the field of novel textile machinery. Because a variety of defects exist in the woven fabric, and a detection algorithm is complicated, when the defects are detected, a specific defect treating process needs to be selected according to the varieties and relevant features of the defects, and a simple single software treatment method obviously can not meet the requirement for real-time control of defect detection. For solving the technical problem, a SCM is used as the core of a control system and used for reading in the varieties and the relevant features of the defects and then controlling a subsequent defect treating process of the woven fabric so that the requirement for real-time control of the defect defection is met, and therefore the treating process of the defects of the woven fabric is accomplished.

Owner:JIANGNAN UNIV

FPGA controller special for defect detection of knitted fabrics

InactiveCN102012688AReal-time fully automatic controlProgramme control in sequence/logic controllersControl systemSoftware engineering

The invention discloses a field programmable gate array (FPGA) controller special for defect detection of knitted fabrics, and belongs to the field of novel textile machinery. The defects of the knitted fabrics are various, and the detection algorithm is complex, so specific defect processing flows need selecting according to the categories and related characteristics of the defects during detecting the defects, and a simple single software processing method obviously cannot meet the real-time control requirement of the defect detection. In order to solve the technical problem, an FPGA is used as the core of a control system, the FPGA system reads the categories and related characteristics of the defects, and the FPGA system controls the subsequent knitted fabric defect processing flows to meet the real-time control requirement of the defect detection and processing so as to finish the processing flows of the defects of the knitted fabrics.

Owner:JIANGNAN UNIV

Special controller for small functionalized knitted fabric equipment of nanofiber surface coating

InactiveCN102520647AOvercome strengthOvercoming productivityProgramme controlComputer controlEngineeringTextile

The invention discloses a special BlackFin controller for functionalized functionalized knitted fabric equipment of nanofiber surface coating, belonging to the field of novel textile machinery. The functionalized knitted fabric equipment of the nanofiber surface coating includes various models, in the processing procedure of the equipment, different technologies need to be regulated, and the regulation is divided into a single regulation mode, a continuous regulation mode and the like, so that the feeding amount and the feeding speed need to be selected automatically according to the technological requirement, and a manual method obviously cannot meet the technical requirement. For solving the technical problem, the BlackFin is used as the core for controlling the system in the invention, and the BlackFin finishes the action of reading the designed feeding amount and the feeding rate to produce different coating products, thereby meeting the requirement on design of the functionalized knitted fabric and finishing the production of the knitted fabrics having necessary functions.

Owner:JIANGNAN UNIV

BlackFin controller special for detecting defects of woven fabrics

InactiveCN102023588AReal-time fully automatic controlProgramme control in sequence/logic controllersControl systemEngineering

A BlackFin controller special for detecting defects of woven fabrics belongs to the field of novel textile machinery. The defects of the woven fabrics are characterized by wide varieties and complex detection algorithm, so the specific defect treatment flow needs to be selected according to the variety and relevant characteristics of the defects during defect detection. Adopting simple single software treatment method obviously can not meet the real-time control requirement of defect detection. In order to solve the technical problem, in the invention, BlackFin is taken as the core of a control system and a BlackFin system is used for reading the variety and relevant characteristics of the defects and controlling the subsequent treatment flows of the defects of the woven fabrics so as to meet the real-time control requirement of defect detection treatment, thus completing the treatment flows of the defects of the woven fabrics.

Owner:JIANGNAN UNIV

Special FPGA (field programmable gate array) controller for functional woven fabric equipment with nano surface coatings

InactiveCN102495575AOvercome strengthOvercoming productivityProgramme controlComputer controlControl systemNanofiber

The invention provides a special FPGA (field programmable gate array) controller for functional woven fabric equipment with nanofiber surface coatings, belonging to the field of novel textile machinery. The functional woven fabric equipment with nanofiber surface coatings has various types, different processes need to be adjusted in the processing course and the adjustment modes are divided into single adjustment and continuous adjustment, so the feed quantity and feeding speed need to be automatically selected according to the process requirements, and obviously, the manual method can not meet the process requirements. In order to solve the technical problem, in the invention, an FPGA is taken as the core of a control system and is used for reading the designed actions of the feed quantity and feeding speed, thus manufacturing different coated products to meet the requirements of functional woven fabric design and further completing production of the woven fabrics with essential functions.

Owner:JIANGNAN UNIV

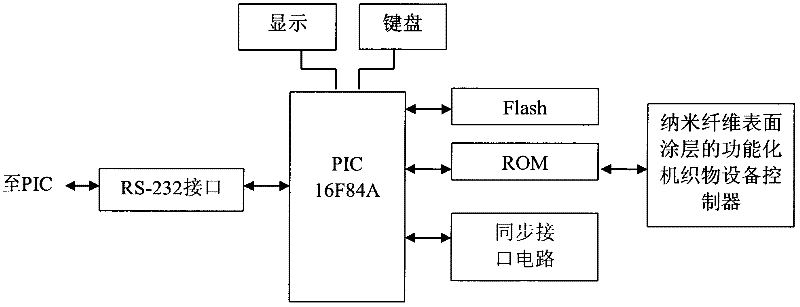

Controller of woven fabric surface nanofiber coating equipment

InactiveCN102520643AOvercome strengthOvercoming productivityProgramme controlComputer controlControl systemNanofiber

The invention discloses a special PIC (Peripheral Interface Controller) for functionalized woven fabric equipment of nanofiber surface coating, belonging to the field of novel textile machinery. The functionalized woven fabric equipment of the nanofiber surface coating includes various models, in the processing procedure of the equipment, different technologies need to be regulated, and the regulation is divided into a single regulation mode, a continuous regulation mode and the like, so that the feeding amount and the feeding speed need to be selected automatically according to the technological requirement, and a manual method obviously cannot meet the technical requirement. For solving the technical problem, the PIC is used as the core for controlling the system in the invention, and the PIC finishes the action of reading the designed feeding amount and the feeding rate to produce different coating products, thereby meeting the requirement on design of the functionalized woven fabrics and finishing the production of the woven fabrics having necessary functions.

Owner:JIANGNAN UNIV

Special programmable logic controller (PLC) for detecting apparent parameters of yarn

InactiveCN102103369AReal-time fully automatic controlProgramme control in sequence/logic controllersYarnControl system

The invention discloses a special programmable logic controller (PLC) for detecting apparent parameters of a yarn, and belongs to the field of a novel textile machine. As more types of the apparent parameters of the yarn exist, when the apparent parameters of the different yarns are detected, the motion speeds of the yarns, the types of detection heads, and the distances between the detection heads and the yarns are different. Therefore, when the apparent parameters of the yarn are detected, the special detection flow is selected according to the type of the apparent parameters of the yarn to be detected. The real-time control requirement of detecting the apparent parameters of the yarn cannot be met by a simple and unique software processing method. In order to solve the problem, the PLC controller system is taken as the core of a control system. The types and the relevant characteristics of the apparent parameters are read by the PLC controller system, and the processing flow of detecting the apparent parameters of the yarn is subsequently controlled by the PLC controller system; therefore, the real-time control requirement of processing the apparent parameters of the yarn is met, and the processing flow of detecting the apparent parameters of the yarn is finished.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com