Intelligent spun-yarn fineness random disturbance control device

A spinning frame and spinning technology, which is applied in textiles and papermaking, and can solve problems such as high-speed feedback spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

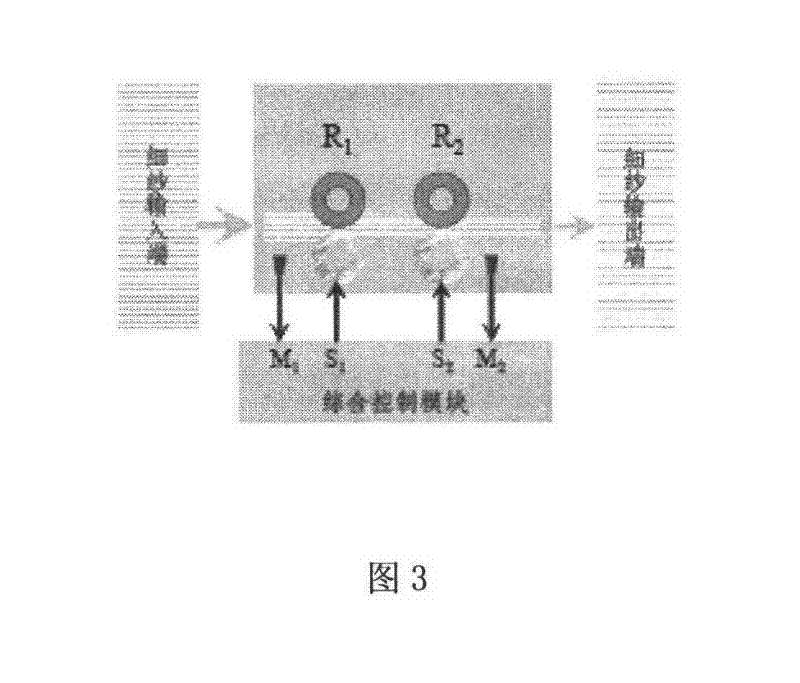

[0018] Such as image 3 As shown, R1 and R2 represent the rear roller and the front roller respectively, M1 and M2 are two image sensors for yarn fineness detection, M1 is used for open-loop control, M2 is used for closed-loop control, and is also used for spectrum analysis. The system mainly adjusts the speed ratio of R1 and R2 by controlling the servo S1 and S2 to achieve the purpose of adjusting the uniformity of the spun yarn. The analysis of the drafting device of spun yarn shows that its control system is mainly divided into four parts: mechanism, sensor, speed regulating mechanism and control mechanism according to its function realization. The overall structure of the control system is as Figure 4 As shown, the sensor collects the yarn fineness signal in real time, the UART is connected to the PC for the debugging stage, the VGA is used to display the image processing result, and the lower computer is used to receive the control signal of the FPGA processing result.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com