Automatic wiring machine based on winding form

A wiring machine and automatic technology, applied in the manufacture of wire harnesses, instruments, electrical components, etc., can solve the problems of low production efficiency, high technical requirements, low yield of wire harness products, etc., to improve yield, reduce technical requirements, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

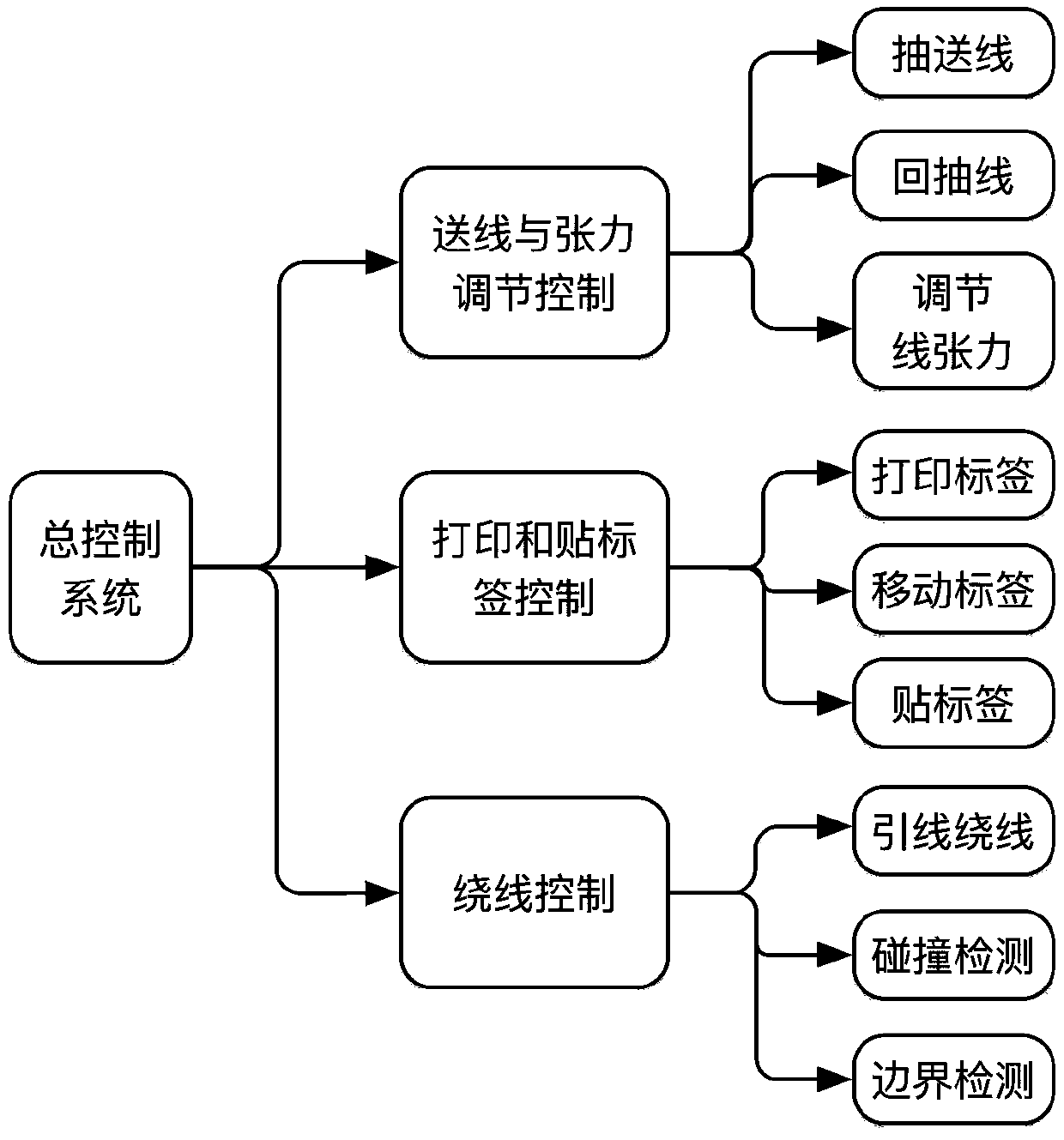

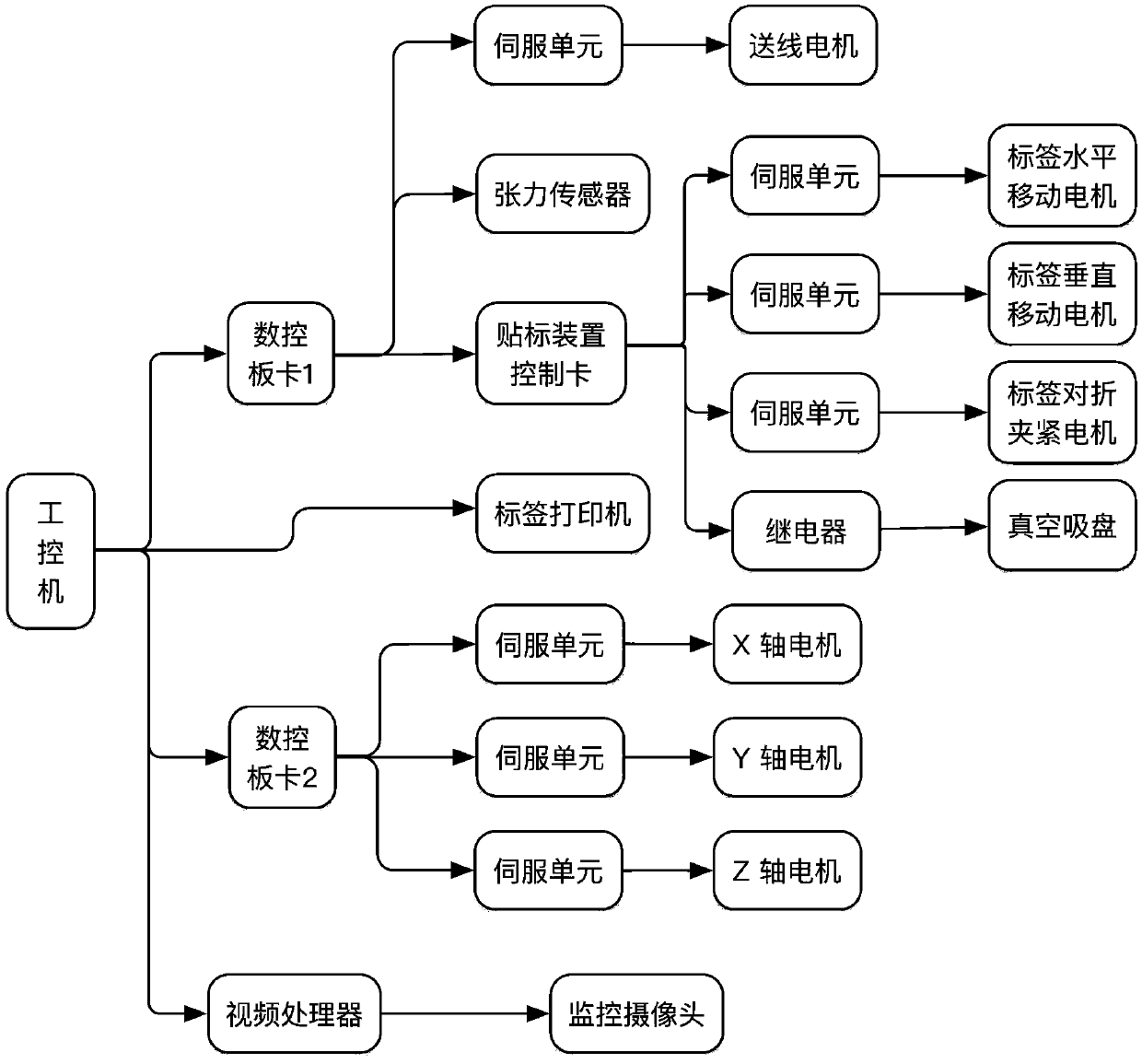

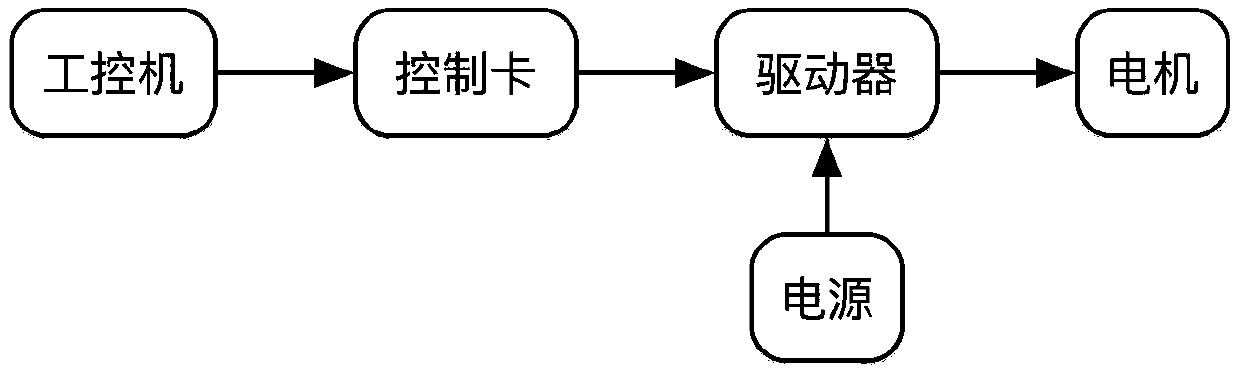

[0016] An automatic wiring machine based on winding, its control system includes an industrial computer, a wire feeding labeling and tension sensing unit, a label printing unit, a wiring unit and a video processing unit, wherein the wire feeding labeling and tension sensing unit , label printing unit, wiring unit and video processing unit are respectively connected with industrial computer; Described wire feeding labeling and tension sensing unit comprise A numerical control board card, wire feeding motor unit, tension sensing unit, labeling control unit, all The A numerical control board is connected to the wire feeding motor through the A servo unit, the A numerical control board is directly connected to the tension sensor, the A numerical control board is connected to the control card of the labeling device, and the control card of the labeling device moves horizontally with the label through the B servo unit The motor is connected to the label vertical moving motor through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com