Dry quenching gas circulation system control method

A technology of gas circulation and control methods, applied in the direction of non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., can solve the problems of high labor intensity for operators, low control level, and adverse effects on production, etc., to achieve The effect of increasing boiler steam production, reducing coke burning loss rate, and improving production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

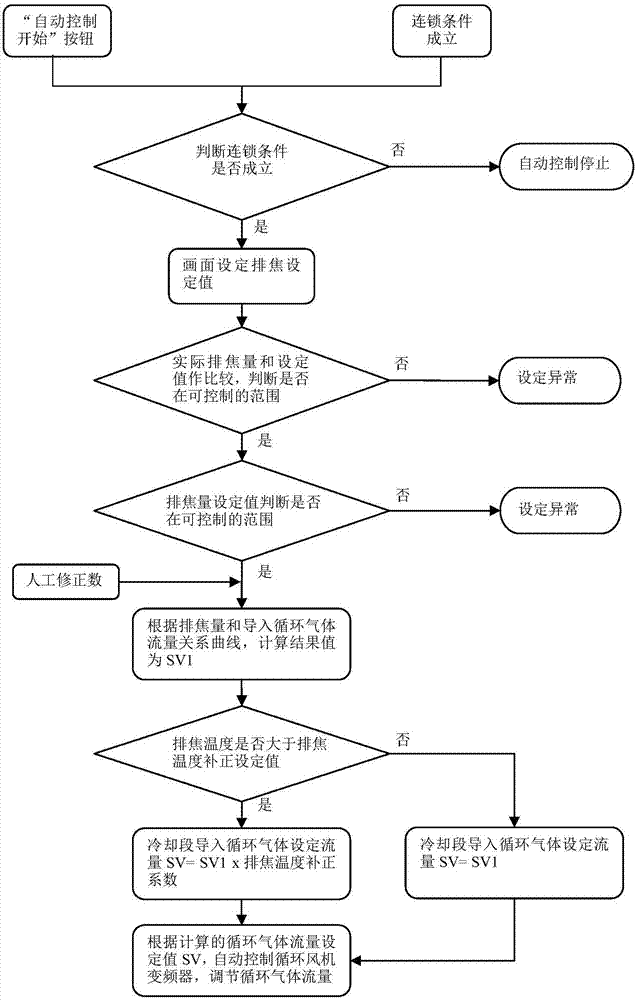

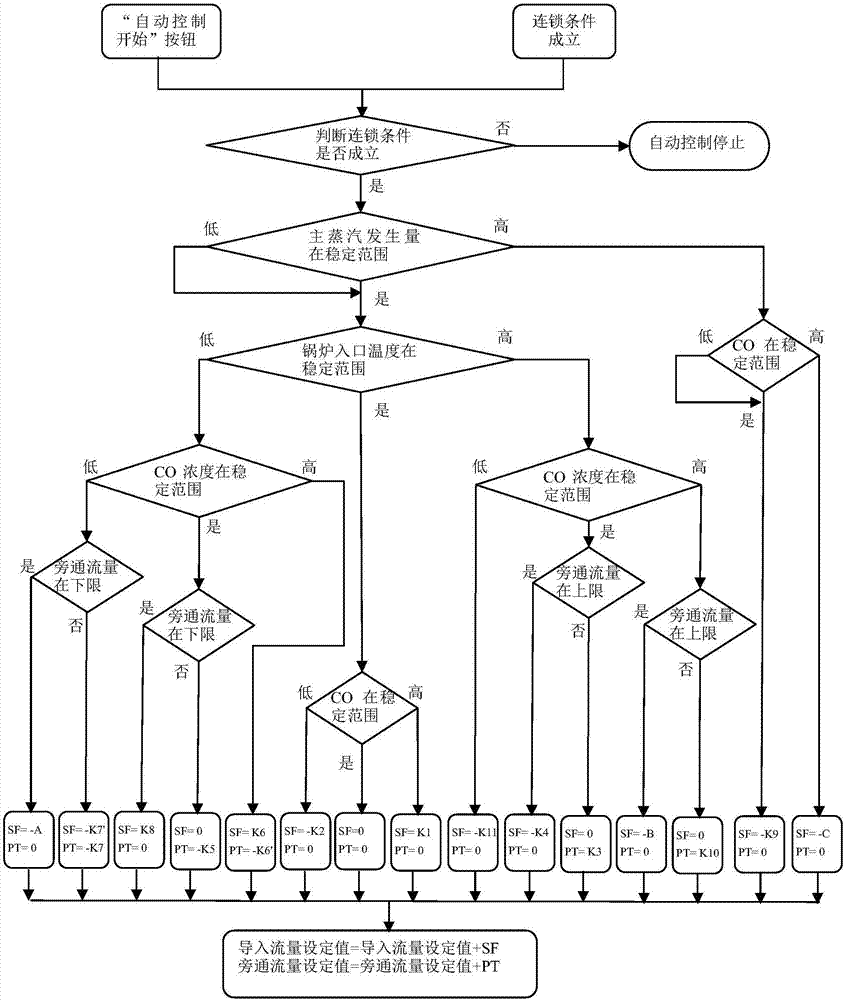

[0046] A set of automatic control method applied to CDQ gas circulation system proposed by the present invention, the specific steps of the entire implementation process are described in detail below:

[0047] 1. Install and configure the required control hardware, software and Ethernet.

[0048] (1) Install computer operating system and control software: The computer adopts Siemens industrial computer and Microsoft windows 764-bit operating system, and the control software adopts Siemens PCS7 8.0SP1 version programming software.

[0049] (2) Install the PLC hardware control equipment: This example adopts the S7 400H series Siemens PLC control equipment adapted to the programming software of Siemens PCS7 8.0SP1 version.

[0050] (3) Set PLC module and communication network: set channels and parameters for PLC hardware, use TCP communication mode for communication, and detect communication network connection.

[0051] (4) Configuration programming software: Write and test the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com