SCM controller special for detecting defects of warp-knitted fabrics

A technology of knitted fabric and controller, which is applied in the field of special SCM controller for warp knitted fabric defect detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

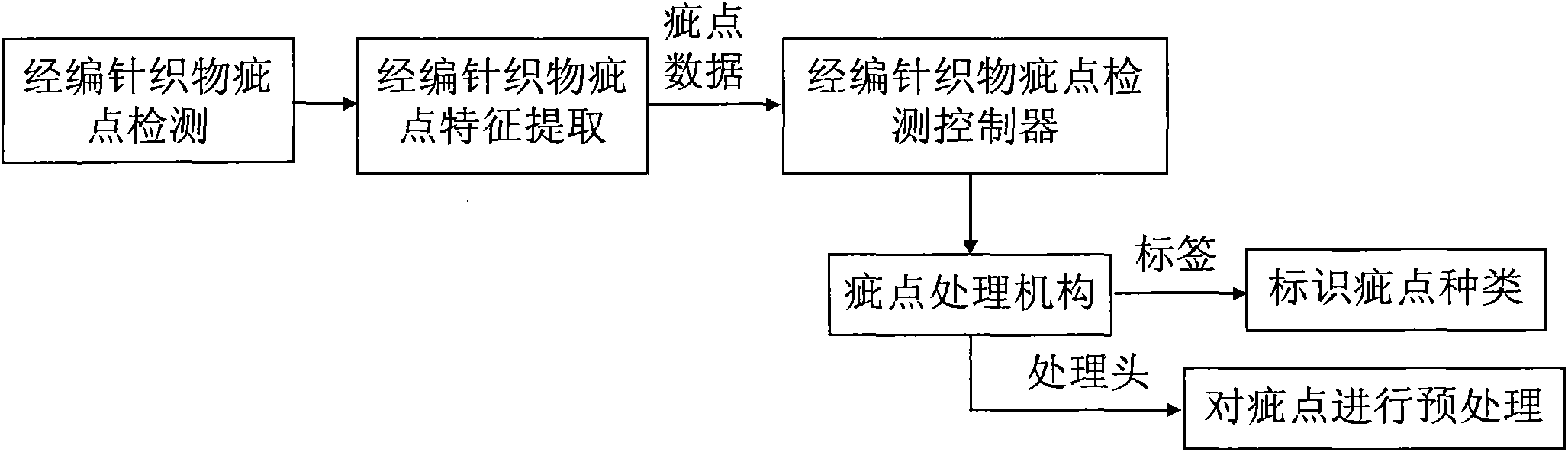

Problems solved by technology

Method used

Image

Examples

Embodiment 1

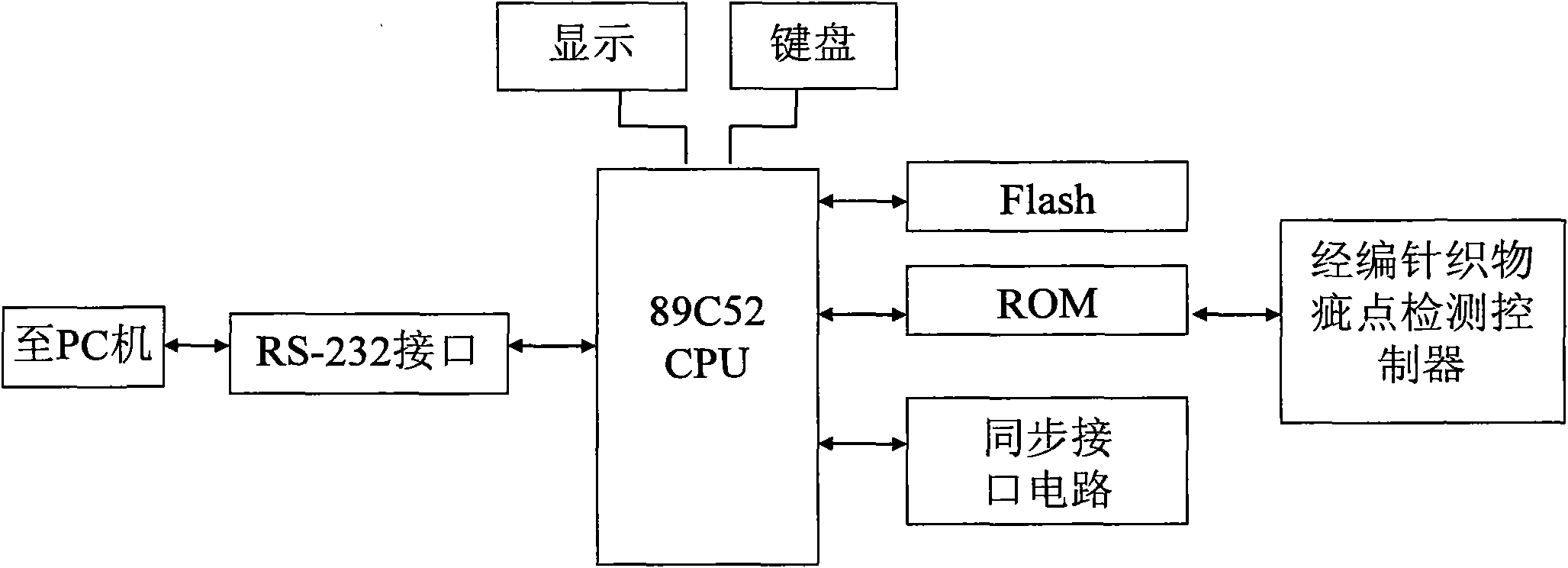

[0016] The entire warp-knitted fabric defect detection controller is mainly composed of 89C52 single-chip microcomputer system, and the warp-knitted fabric defect detection processor is mainly composed of a single-chip microcomputer, storage body, communication interface and keyboard display, etc. Process the defect data of warp knitted fabrics in , and the composition block diagram is as follows figure 2 shown. When the warp-knitted fabric defect data is changed, the system microcomputer is used to input the defect data through the RS232 interface and stored in the warp-knitted fabric defect processor.

[0017] Warp-knitted fabric defect memory is used to store defect data, using AM29F016D flash memory with a capacity of 1.5M bytes; keyboard and display are used to input warp-knitted fabric structure parameters and other working parameters; RS-232 serial The line communication interface receives the defect data transmitted from the upper computer; the single-chip microcompu...

example 2

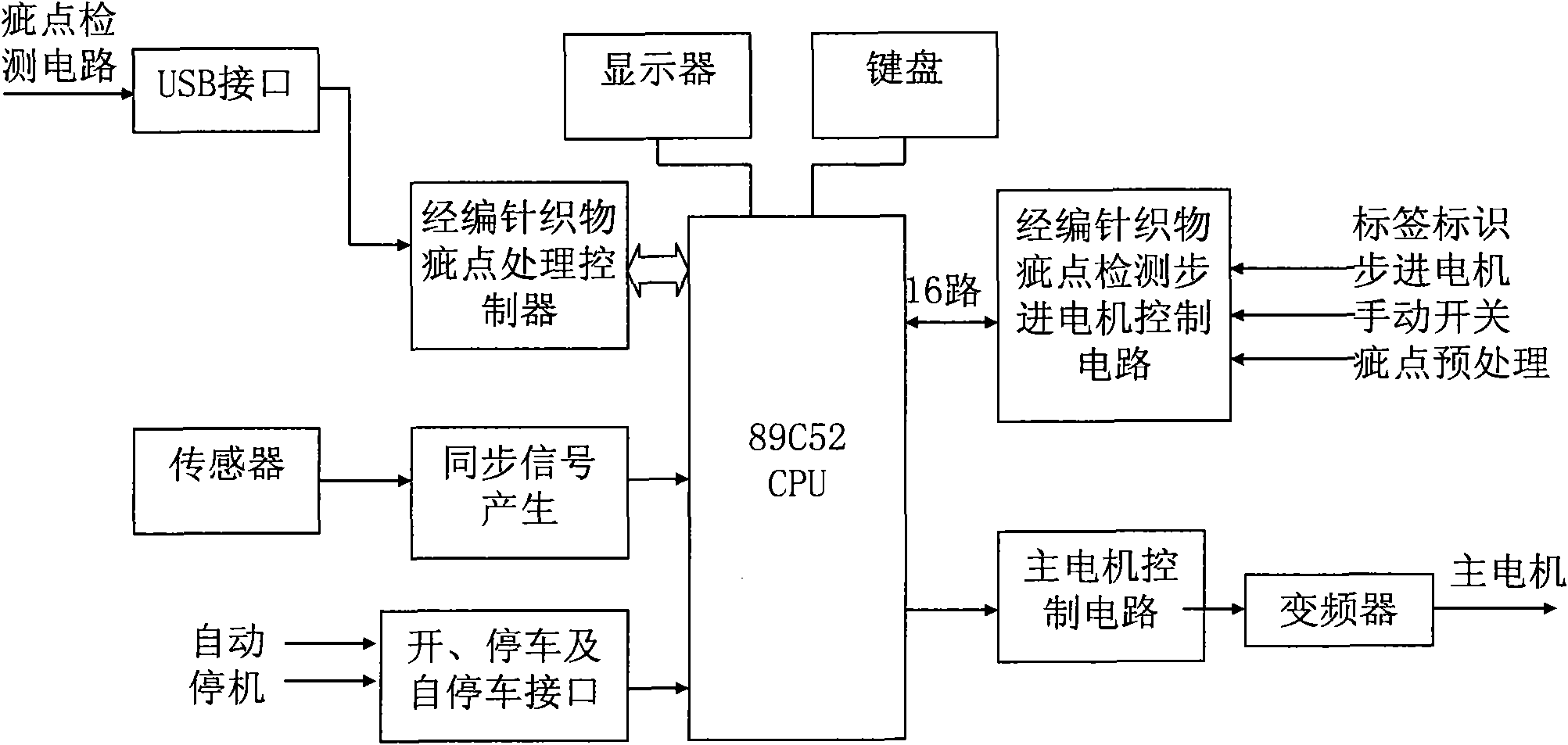

[0021] The entire warp knitted fabric defect detection controller is mainly composed of 8086 single-chip microcomputer system, and the fabric defect processor is mainly composed of single-chip microcomputer, storage body, communication interface and keyboard display, etc., which are used to receive, store and process fabric defects during work Data, composed of block diagrams such as Figure 4 shown. When the fabric defect data is changed, the processed fabric defect data is stored in the U disk, and the fabric defect data of the U disk is read into the memory of the fabric defect processor through the USB interface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com