Square tube type vehicle support with toolrooms

A tool room and vehicle technology, applied in the field of vehicle supports, can solve the problems of trouble, small pressure bearing area, and hard drilling out of the vehicle bottom, etc., and achieves the effects of low cost, supporting vehicle safety, and increasing pressure bearing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will further describe the present invention in conjunction with the accompanying drawings of the embodiment, which will help the public to understand the technical content and effect of the case, but the description of the embodiment does not constitute a limitation to the technical solution. Any transformation that is merely equivalent in form should be regarded as the scope of the technical solution of this case.

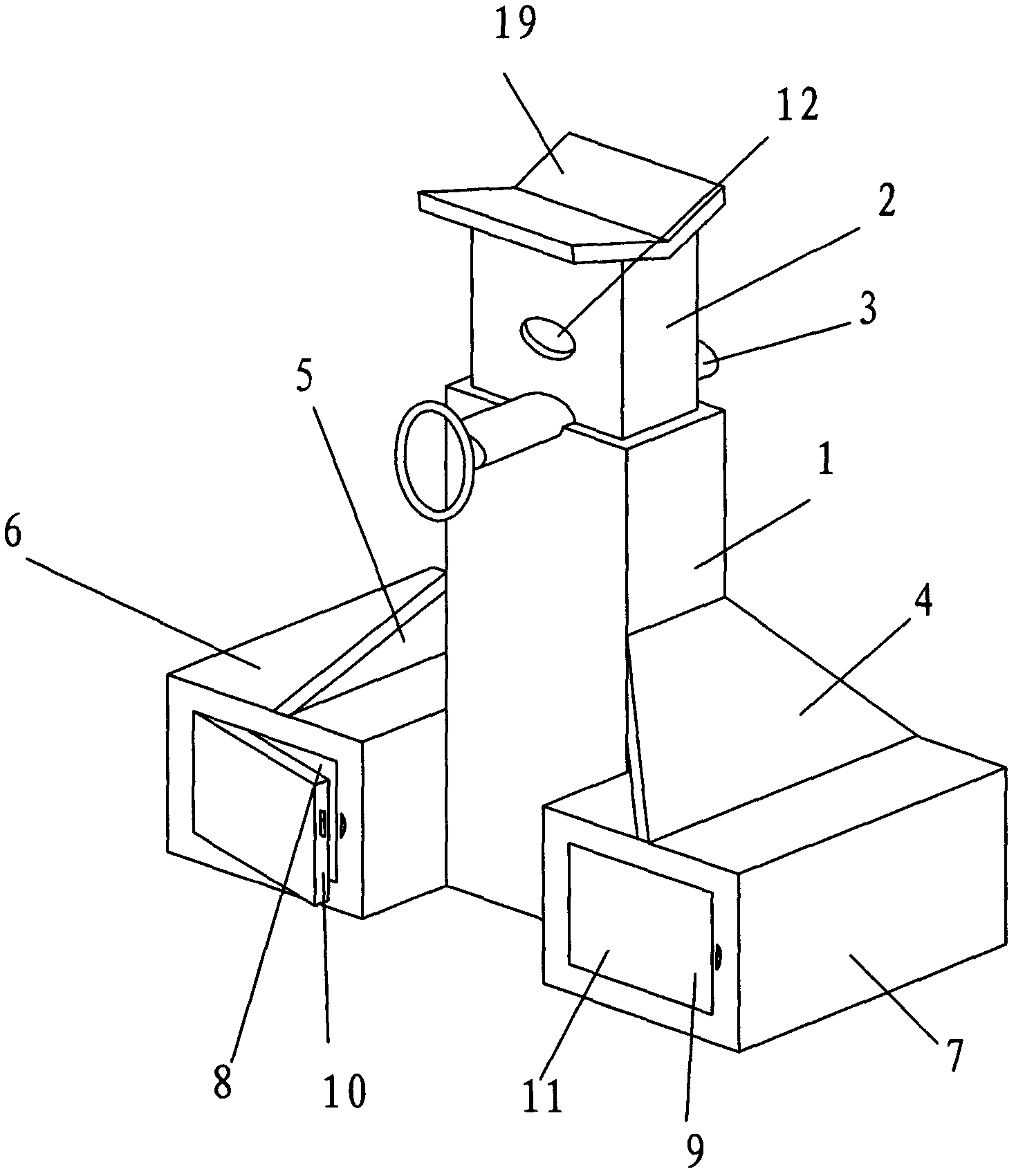

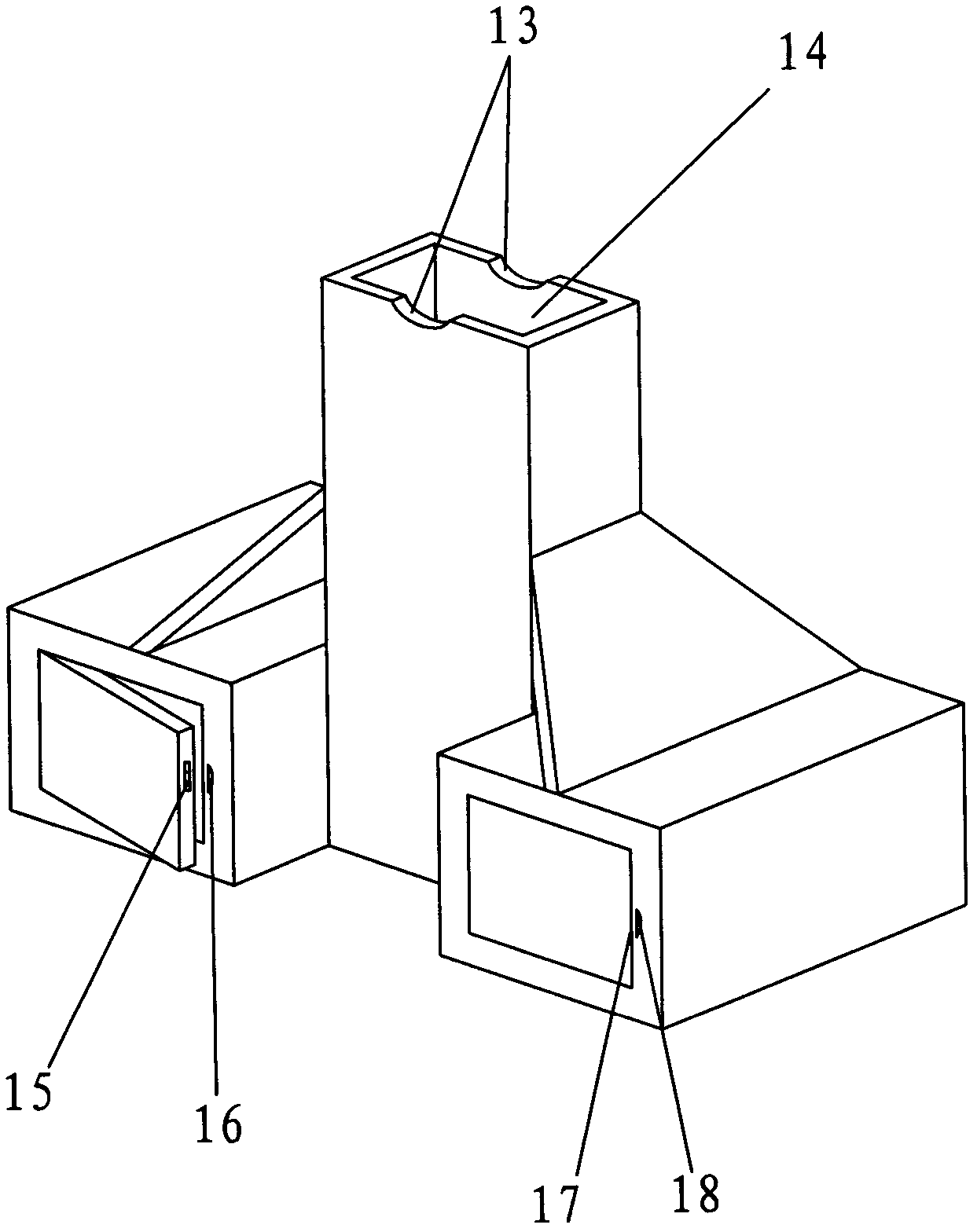

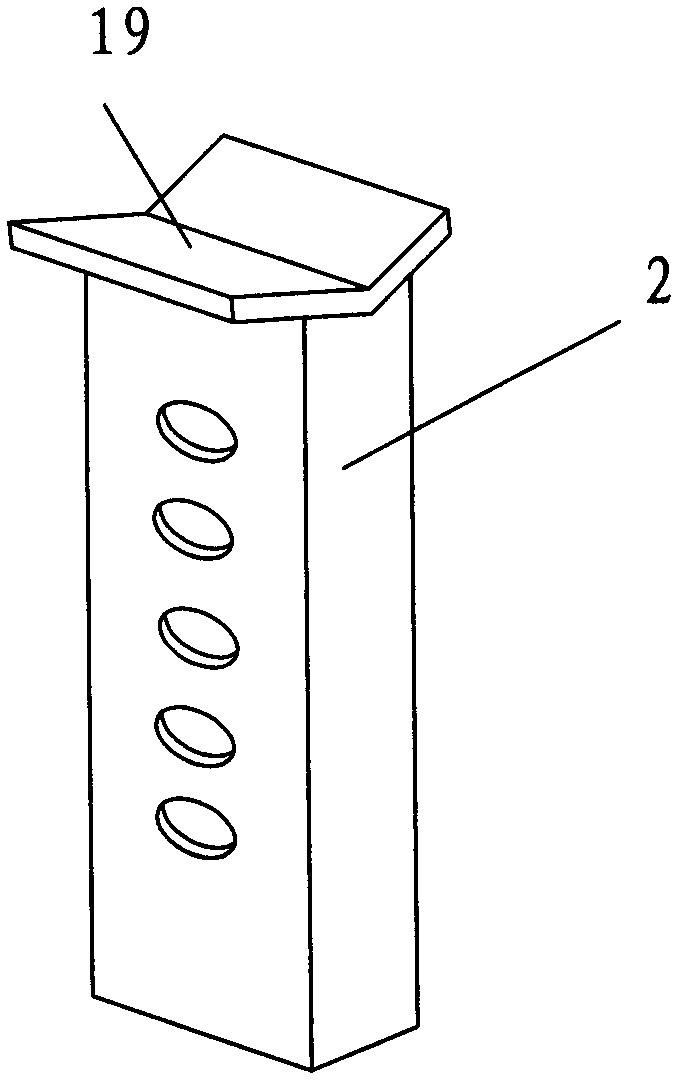

[0015] As can be seen from the accompanying drawings, the structural composition of the embodiment of the present invention is such that the two inner surfaces of the first square tube support pad 6 and the second square tube support pad 7 are welded to the two sides of the square tube bottom column 1 respectively, The two upper planes of the square tube support pad 6 and the second square tube support pad 7 are respectively reinforced by the left welding reinforcement plate 5 and the right welding reinforcement plate 4 and the left side and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com