Triple-effect adsorption, refrigeration and circulation system

An adsorption refrigeration and circulation system technology, applied in the field of thermodynamic systems, can solve the problem of not being able to continuously output cooling capacity multiple times, and achieve the effect of improving system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

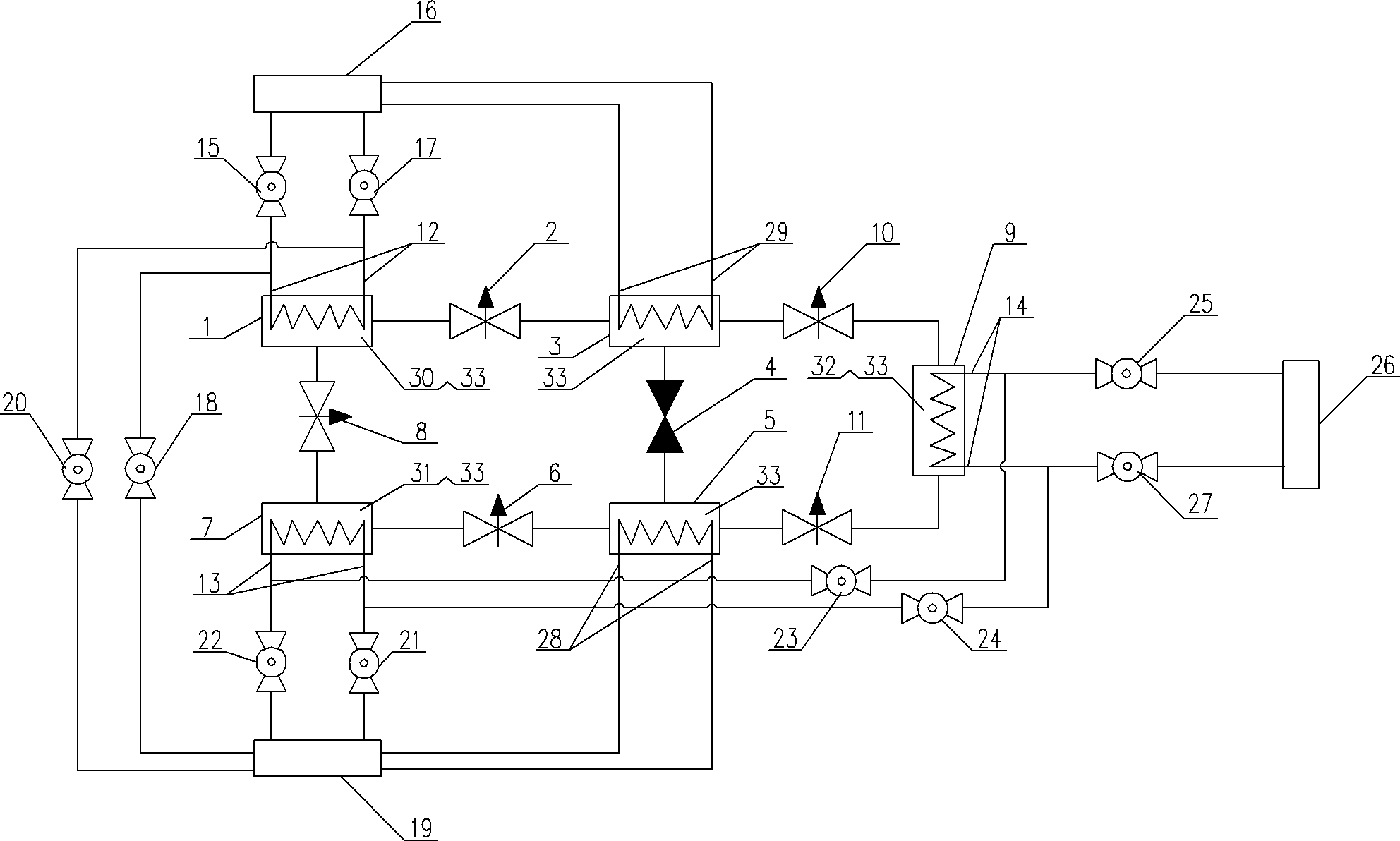

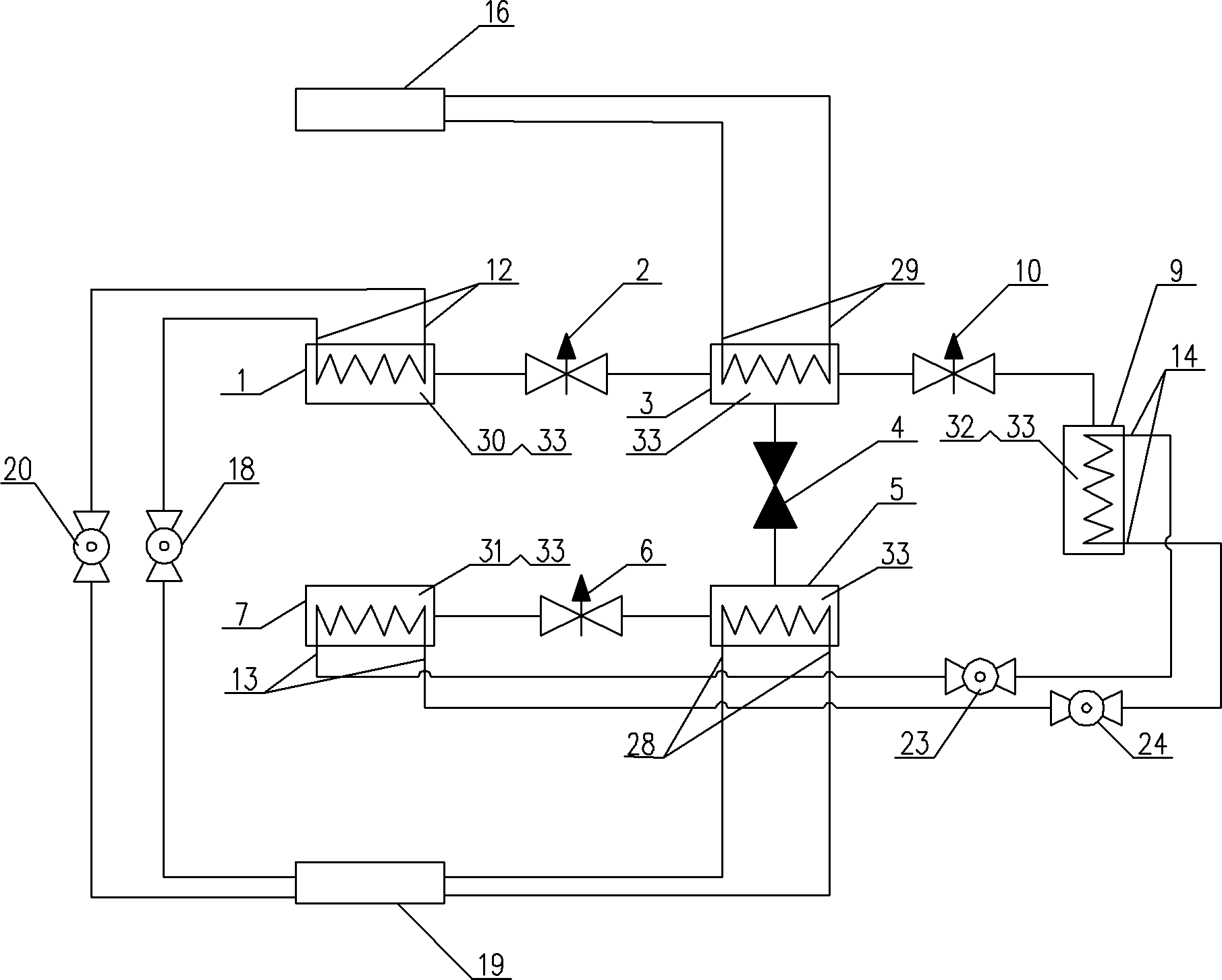

[0022] Such as figure 1 The shown embodiment one of the three-effect adsorption refrigeration cycle system of the present invention mainly includes the first reactor 1 with the first solid adsorbent 30 inside and the first reactor 1 with the second solid adsorbent 31 inside. Two reactors 7, the third reactor 9, the evaporator 3, the condenser 5, the first heat source 16, the second heat source 19, the third heat source 26 that are provided with the third solid adsorbent 32 inside; the first reactor 1 and A first gas regulating valve 2 is provided on the pipeline between the evaporator 3, a throttle valve 4 is provided on the pipeline between the evaporator 3 and the condenser 5, and a throttle valve 4 is provided on the pipeline between the condenser 5 and the second reactor 7. A second gas regulating valve 6 is provided, a third gas regulating valve 8 is provided on the pipeline between the second reactor 7 and the first reactor 1, and a third gas regulating valve 8 is provid...

Embodiment 2

[0039] Such as figure 1 The shown embodiment two of the three-effect adsorption refrigeration cycle system of the present invention, the system structure of this embodiment is the same as that of embodiment one, the gas adsorbate 33 filled in the system is ammonia, the first reactor 1 filled with Solid adsorbent 30 is PbCl 2 , the second solid adsorbent 31 filled in the second reactor 7 is MnCl 2 , the third solid adsorbent 32 filled in the third reactor 9 is NiCl 2 . The first heat source 16 is low-temperature brine with a temperature of 0°C. The second heat source 19 is air with a temperature of 30°C. The third heat source 26 is a boiler with a temperature of 350°C.

[0040] The operation process of this embodiment is specifically as follows:

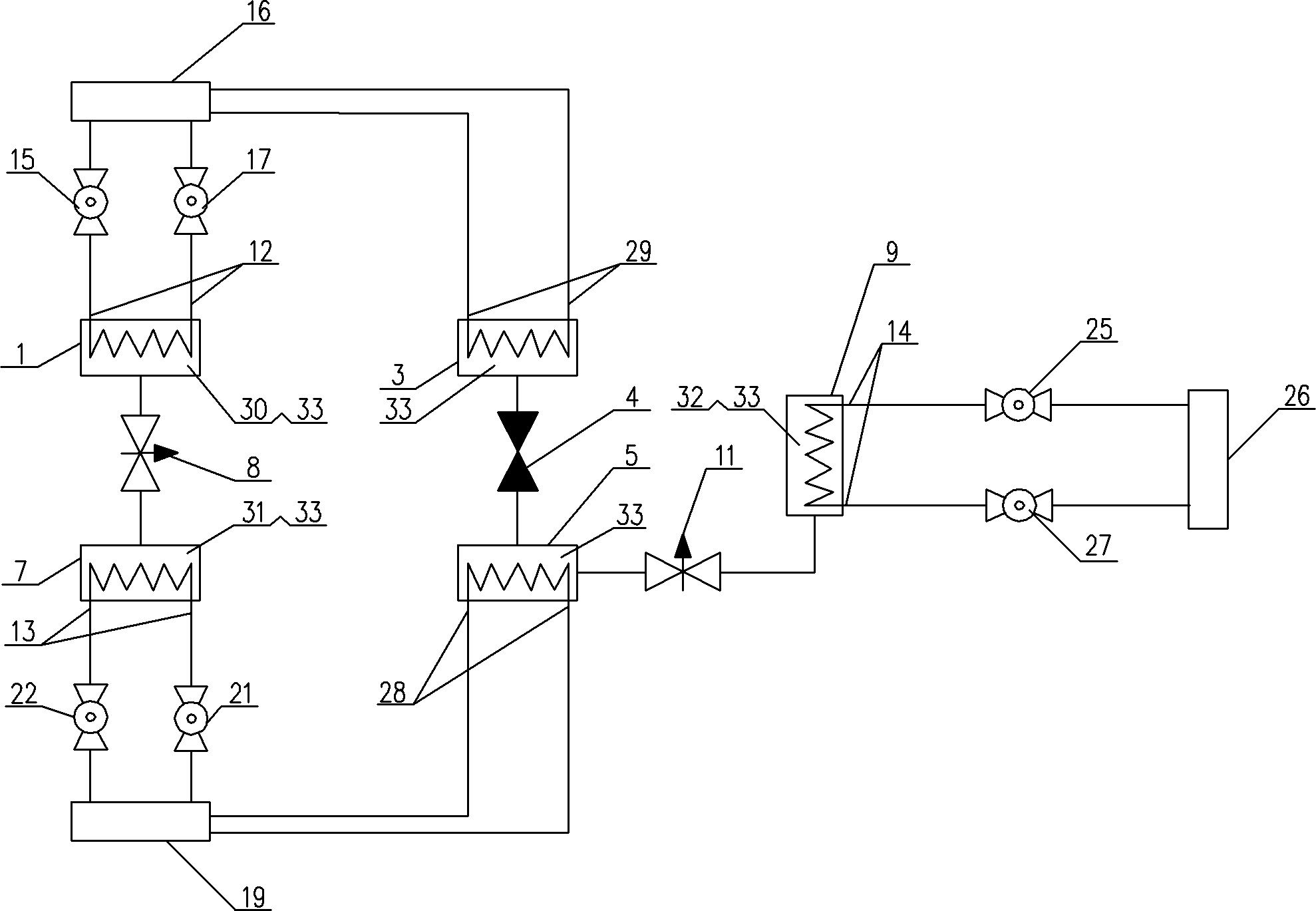

[0041] Such as figure 2 The first stage operation process of the three-effect adsorption refrigeration cycle system of the present invention shown, the first stage: open the first gas regulating valve 2, the second gas regulat...

Embodiment 3

[0047] Such as figure 1 The third embodiment of the three-effect adsorption refrigeration cycle system of the present invention is shown. The system structure of this embodiment is the same as that of the first embodiment. The gas adsorbate 33 filled in the system is ammonia, and the first reactor 1 filled with The solid adsorbent 30 is BaCl 2 , the second solid adsorbent 31 filled in the second reactor 7 is PbCl 2 , the third solid adsorbent 32 filled in the third reactor 9 is CoCl 2 . The first heat source 16 is low-temperature brine with a temperature of 0°C. The second heat source 19 is ambient water with a temperature of 20°C. The third heat source 26 is a solar heat collector with a temperature of 250°C.

[0048] The operation process of this embodiment is specifically as follows:

[0049] Such as figure 2The first stage operation process of the three-effect adsorption refrigeration cycle system of the present invention shown, the first stage: open the first gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com