Shape-following slicking device for gap of steam-sealing ring of steam turbine

A steam seal ring and steam turbine technology, which is applied to machine tools, grinders, and metal processing equipment designed for grinding the rotating surface of workpieces, can solve the problems of high transportation cost, low work efficiency, heavy weight, etc. Easy to measure and adjust, easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

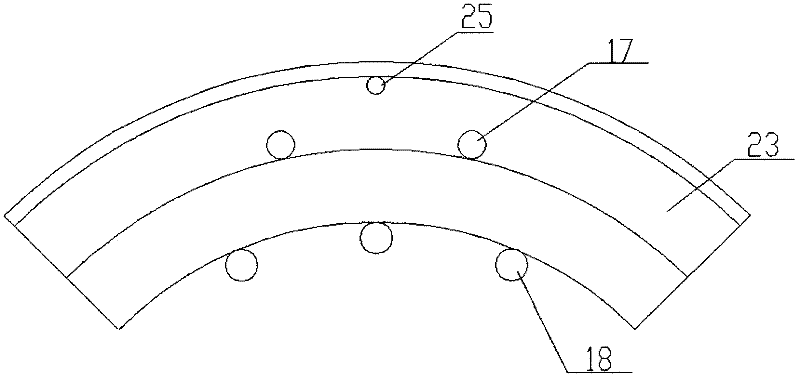

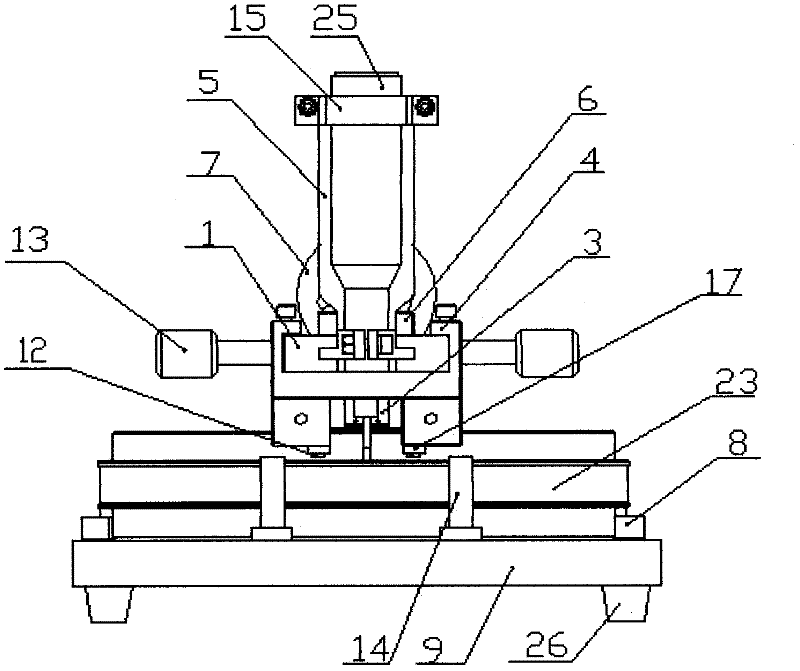

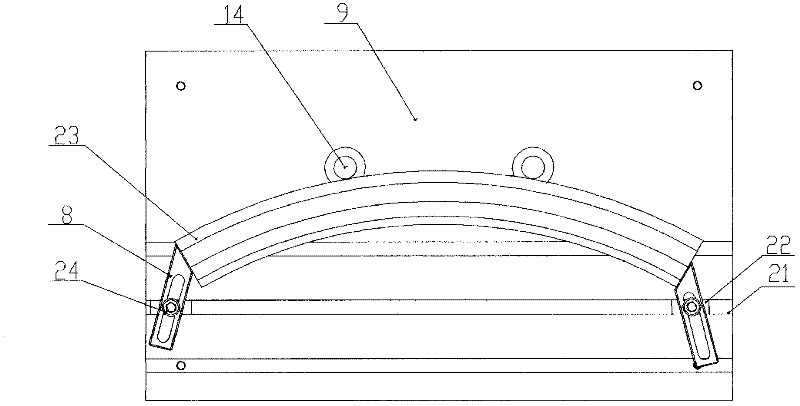

[0017] If the scraping inner diameter is Φ600mm steam seal ring, install the steam seal ring 23 on the mounting seat 9, clamp the steam seal ring through the fixed shaft 14 and the side plate 8, and the outer bearing 17 and load bearing 16 on the outer bearing fixing frame 4 Close to the shoulder of the seal ring on the outside of the seal ring, rotate the flat top wire 20 to make the inner bearing 18 close to the seal teeth on the inside of the seal ring, and rotate the hand wheel 7 to make the cutter head of the straight grinder touch the back arc of the seal ring On the surface, adjust the handwheel according to the required cutting amount, pull the handle 13 to repair and scrape the back arc of the steam seal ring 23, and adjust the feed amount of the straight grinder cutter head at any time during the scraping process. The steam seal ring 23 can adjust the handwheel 7 and change the cutting amount while repairing and scraping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com