Paper feeding mechanism

A paper feeding mechanism and oblique hole technology, applied in the directions of printing, printing devices, etc., can solve the problems of printing paper wrinkles, reduce work efficiency, etc., and achieve the effect of preventing paper jams in the printer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

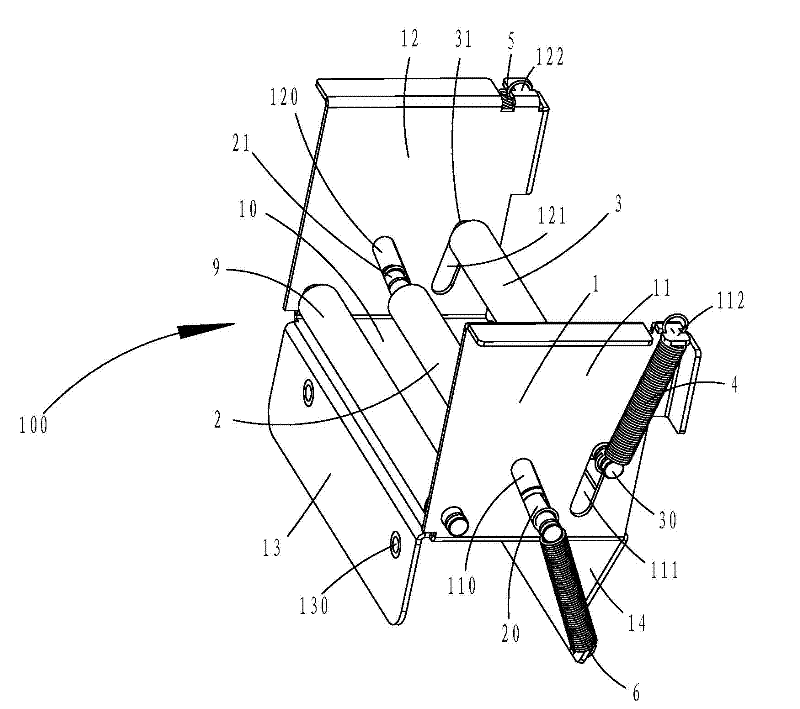

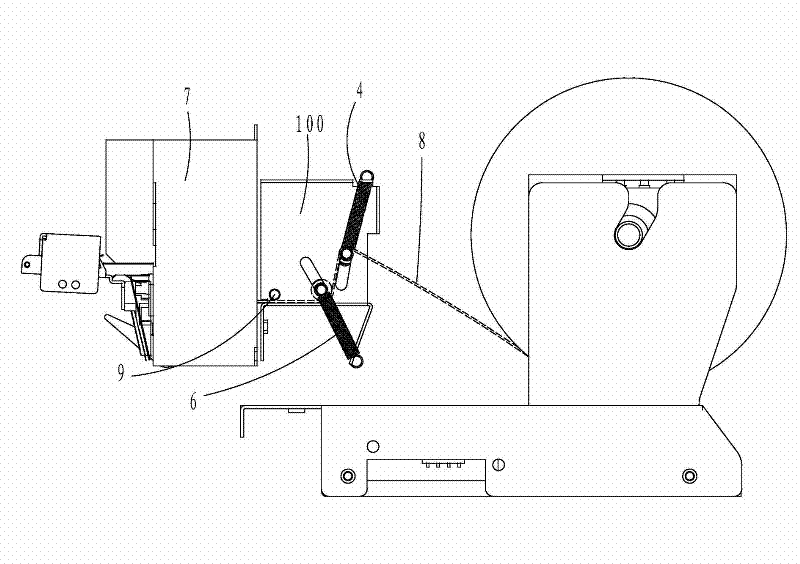

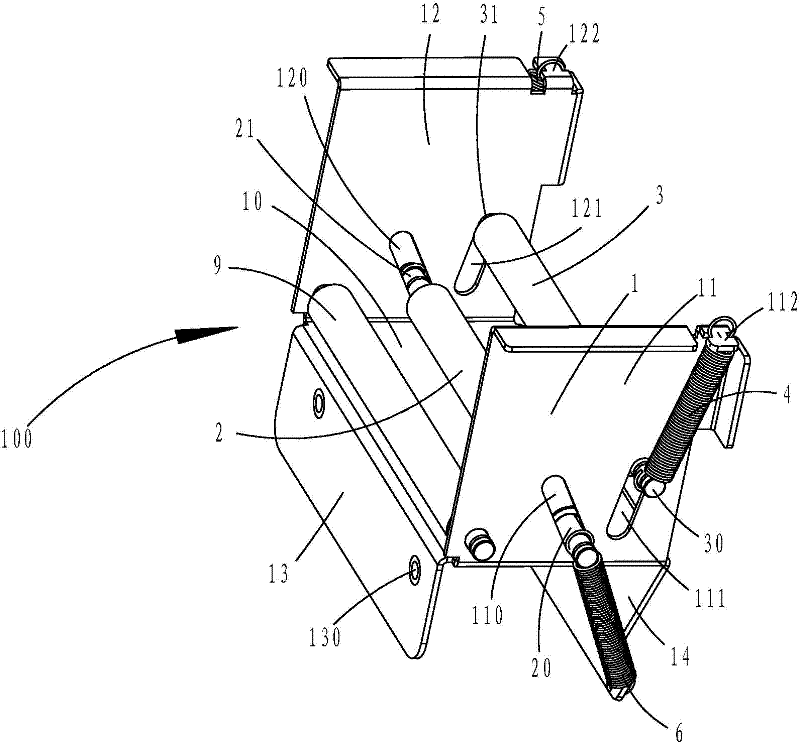

[0010] see figure 1 and figure 2 , a paper feeding mechanism 100, which includes: a housing 1 and first and second rotating shafts 2, 3 installed in the housing 1. In this embodiment, two rotating shafts are provided. Of course, in other implementations In the mode, the number of rotating shafts can be increased or decreased according to specific needs. The housing 1 includes: a base 10 , first and second side walls 11 and 12 bent upward from both sides of the base 10 , and first and second ends bent downward from both ends of the base 10 Walls 13 and 14 , the first end wall 13 is provided with several installation holes 130 , and fixing parts are installed in the installation holes 130 , so as to fix the paper feeding mechanism 100 and the printer. The first side wall 11 is provided with a first inclined hole 110 and a second inclined hole 111, and the second side wall 12 is provided with a third inclined hole 120 and a fourth inclined hole 121. One end of the first rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com