Vehicle chassis with tread adjusted in stepless adjustment mode

A stepless adjustment and wheelbase technology, applied in vehicle components, substructures, transportation and packaging, etc., can solve the problems of poor work reliability and stability, high failure rate, inconvenient wheelbase adjustment, etc., to achieve centralization control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

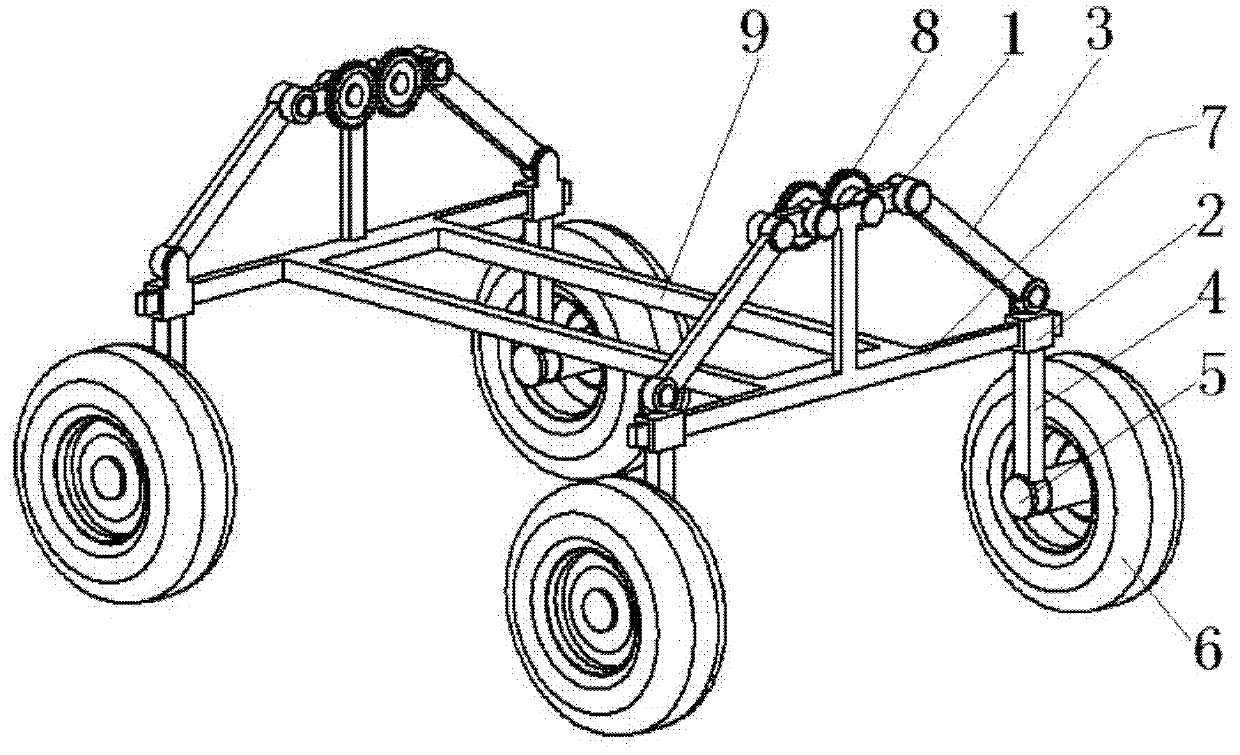

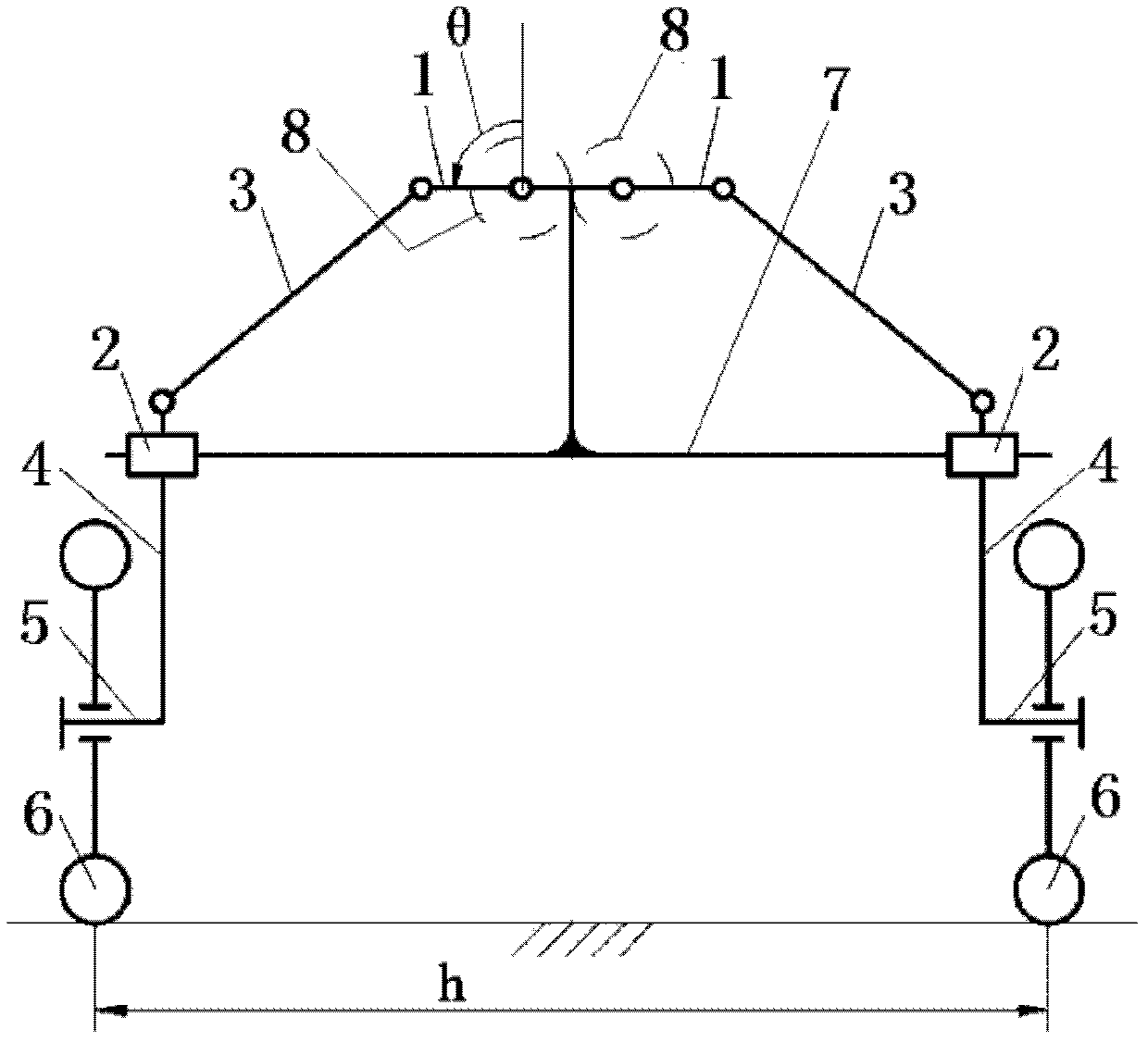

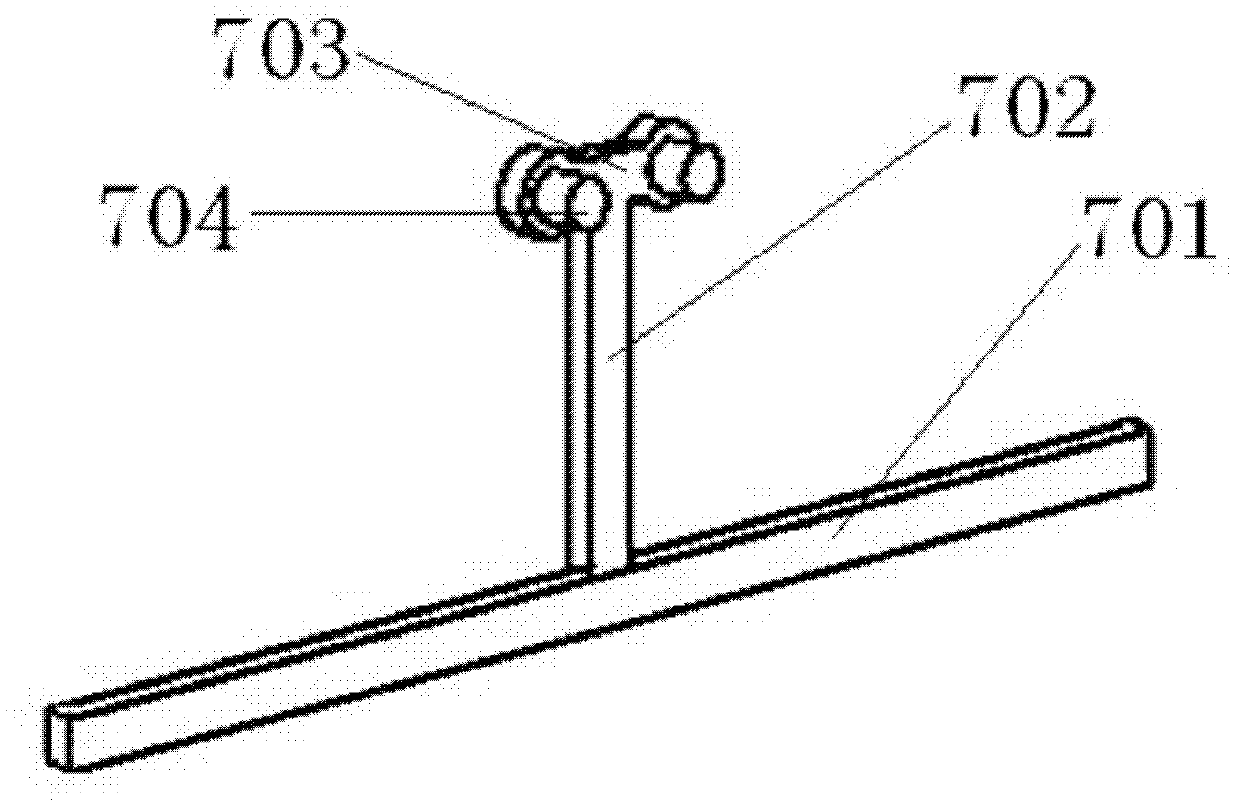

[0024] figure 1 It is the overall diagram of the vehicle chassis with stepless wheelbase adjustment. The vehicle chassis with stepless wheelbase adjustment is composed of two sets of vehicle wheelbase stepless adjustment devices and frame 9. The two sets of vehicle wheelbase stepless adjustment devices share the longitudinal direction of the vehicle chassis. The central plane is arranged front and back according to the wheel base on the rectangular vehicle frame 9 , and the front and rear two groups of vehicle wheelbase stepless adjustment devices are respectively affixed to the front end and the rear end of the vehicle frame 9 through the horizontal track 701 of the bracket 7 .

[0025] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com