Embryo pressing rod suitable for bottle embryo pressing device of bottle-making machine

A bottle-making machine and bottle-pressing technology, applied in the field of components, can solve the problems of large force on the preform tail rod, low bottle-making yield, and lower bottle-making yield, so as to improve the bottle-making yield and eliminate bottle-making. Yield reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below by embodiment and accompanying drawing thereof, the present invention is described in further detail:

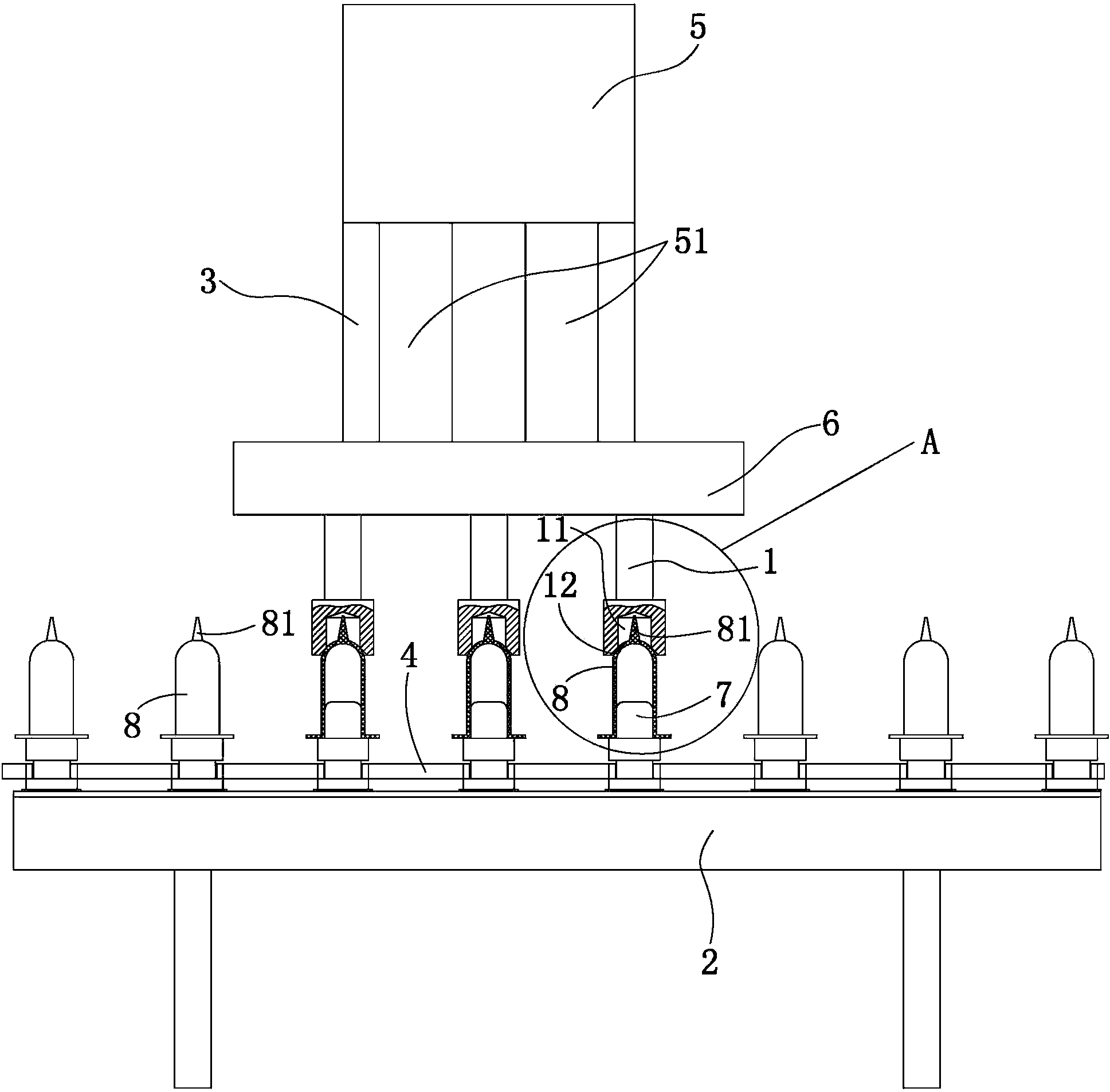

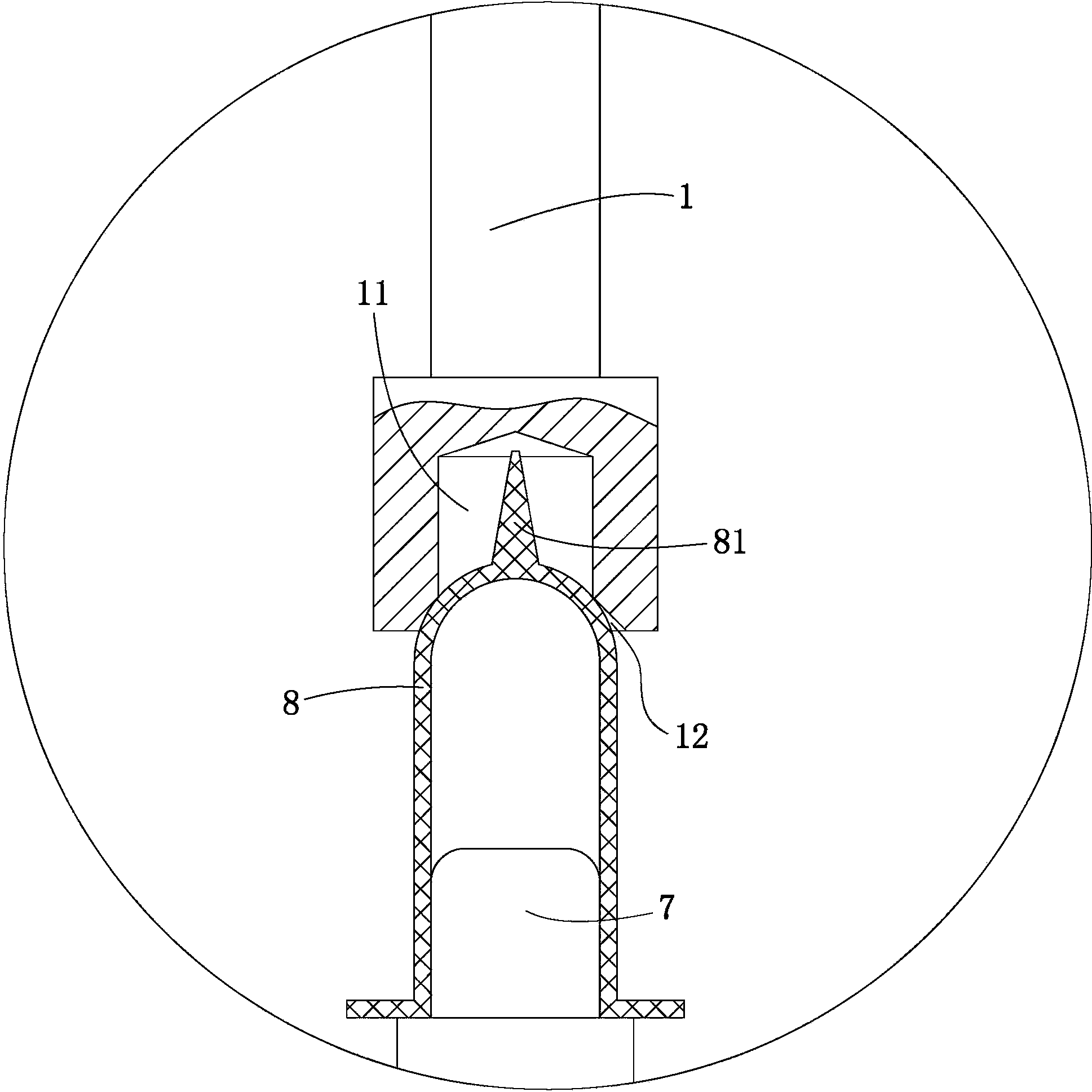

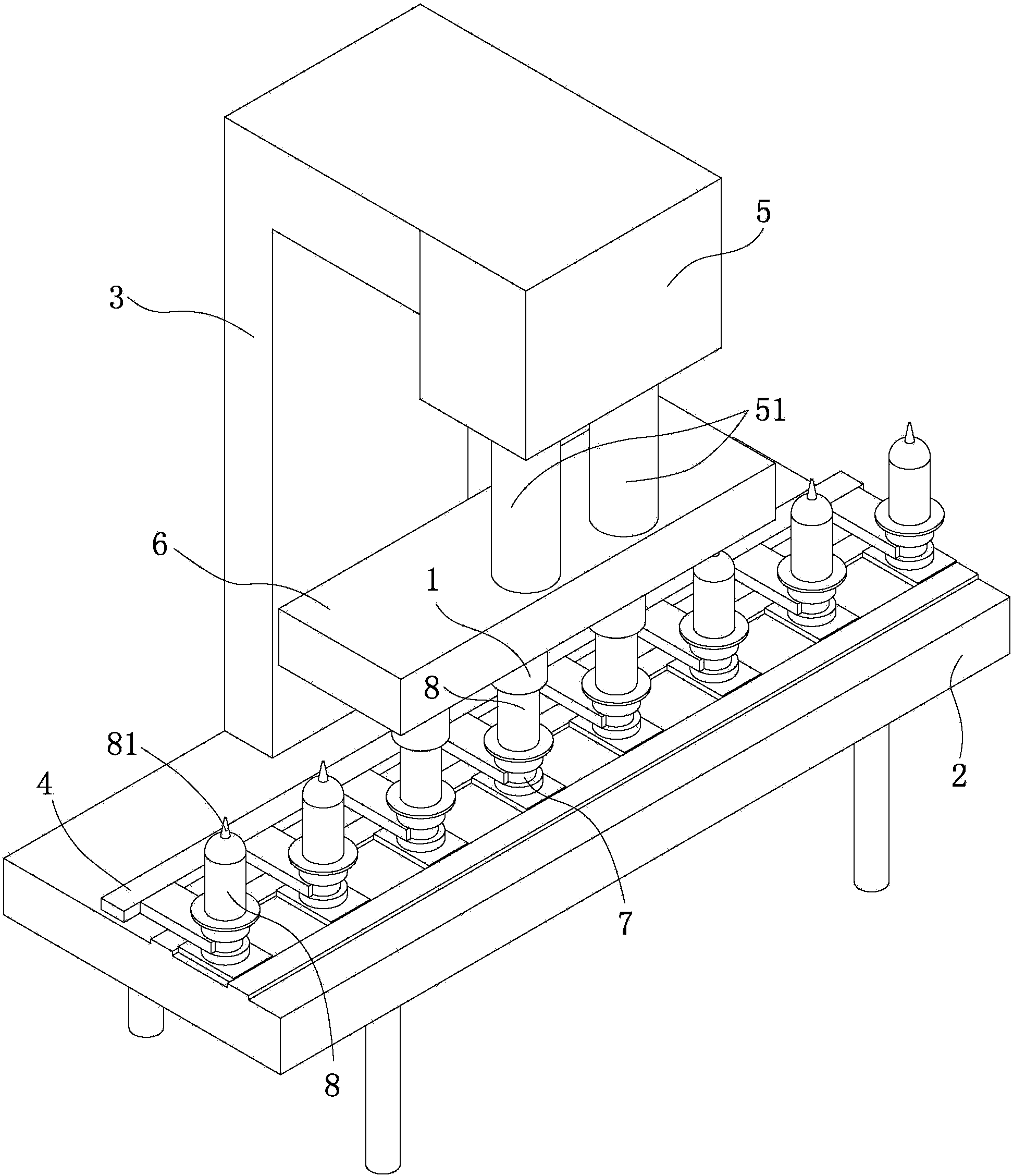

[0017] see figure 1 — Figure 4 , the preform rod 1 is a vertical rod body, the lower end of the rod body has a circular concave hole 11 which is concentric with the center line and for the tail rod 81 of the preform 8 to penetrate, and the depth of the concave hole 11 is greater than the length of the tail rod 81 , the inner diameter of the concave hole 11 is smaller than the outer diameter of the preform 8 . The lower end of the concave hole 11 has a bell mouth 12 with a small top and a big bottom. The diameter of the upper circular opening of the bell mouth 12 is equal to the inner diameter of the concave hole 11. The outer diameter, the ratio of the depth of the bell mouth 12 to the depth of the concave hole 11 is 1:5.9.

[0018] Existing preform pressing device of bottle making machine includes: horizontal frame 2, connecting frame 3 and horizontal revol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com