Ventilated type vehicle chair back

A ventilated, vehicle technology, applied in the field of vehicle seat backs, can solve the problems of not easy to dissipate heat, the driver's back is sultry, and the installation is complicated, and the effect of preventing the back from being cold is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The structural features and expected effects of the present invention will be described below with preferred embodiments, but they are not intended to limit the protection scope of the present invention.

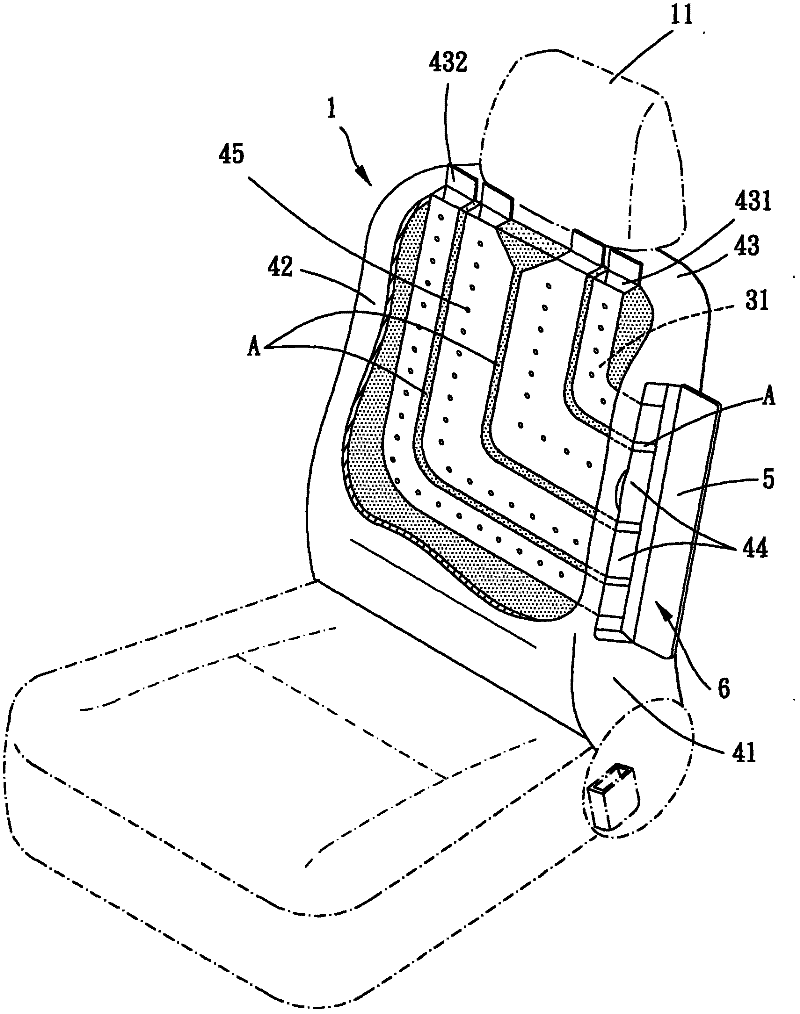

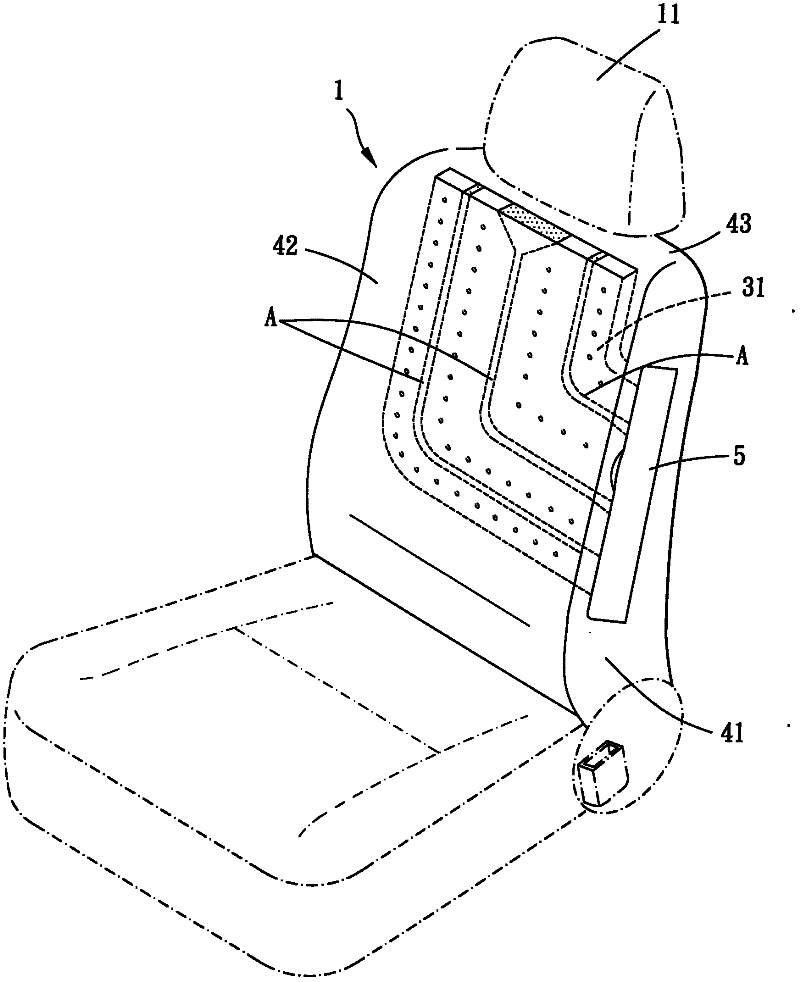

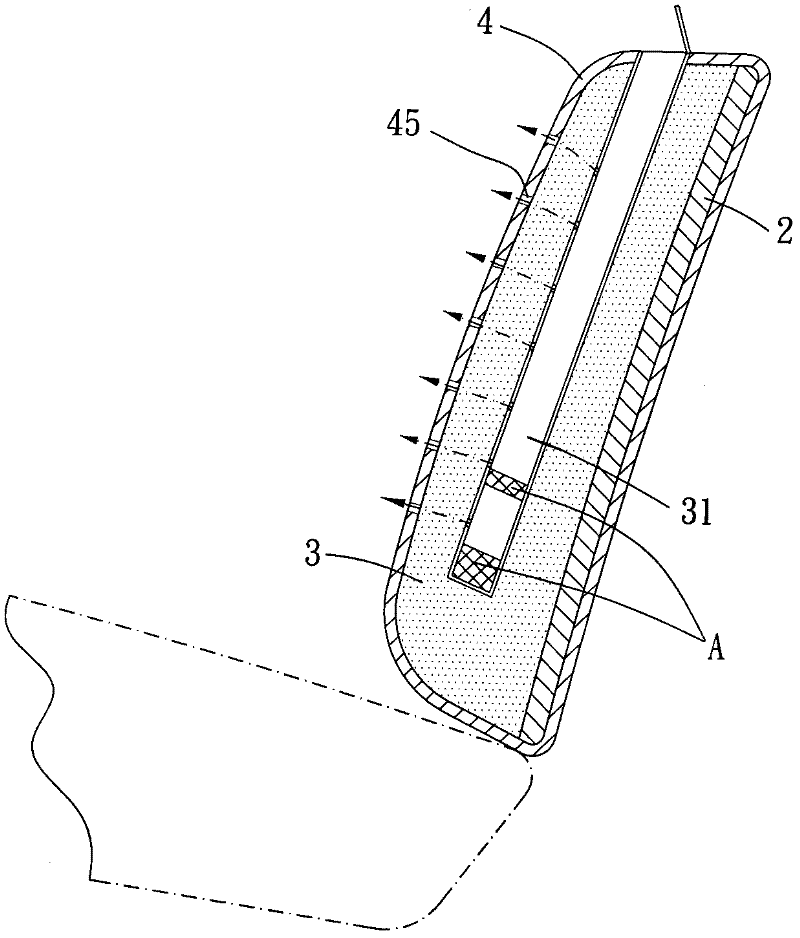

[0033] Please refer to Figure 1 to Figure 3 , in a preferred embodiment of the present invention, the ventilated vehicle seat back includes a body 1, the body 1 has a support portion 2, a foam layer 3, a seat cover 4 and an air deflector 5, the support portion 2 is supported by the foam The layer 3 is covered, and the support portion 2 is formed with a first joint portion, and the seat cover 4 is wrapped on the outside of the foam layer 3 to form the main body 1 . The aforementioned main body 1 further defines two side surfaces 41, a leaning surface 42 and a top surface 43. The leaning surface 42 is for the human body to lean against. Among the two sides 41, there are more than one entrance openings on the side far away from the vehicle door. The air inlet 44 and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap