Core wire supply apparatus and spinning machine having the same

A technology of supplying device and core thread, which is applied in the direction of continuous winding spinning machine, spinning machine, open-end spinning machine, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

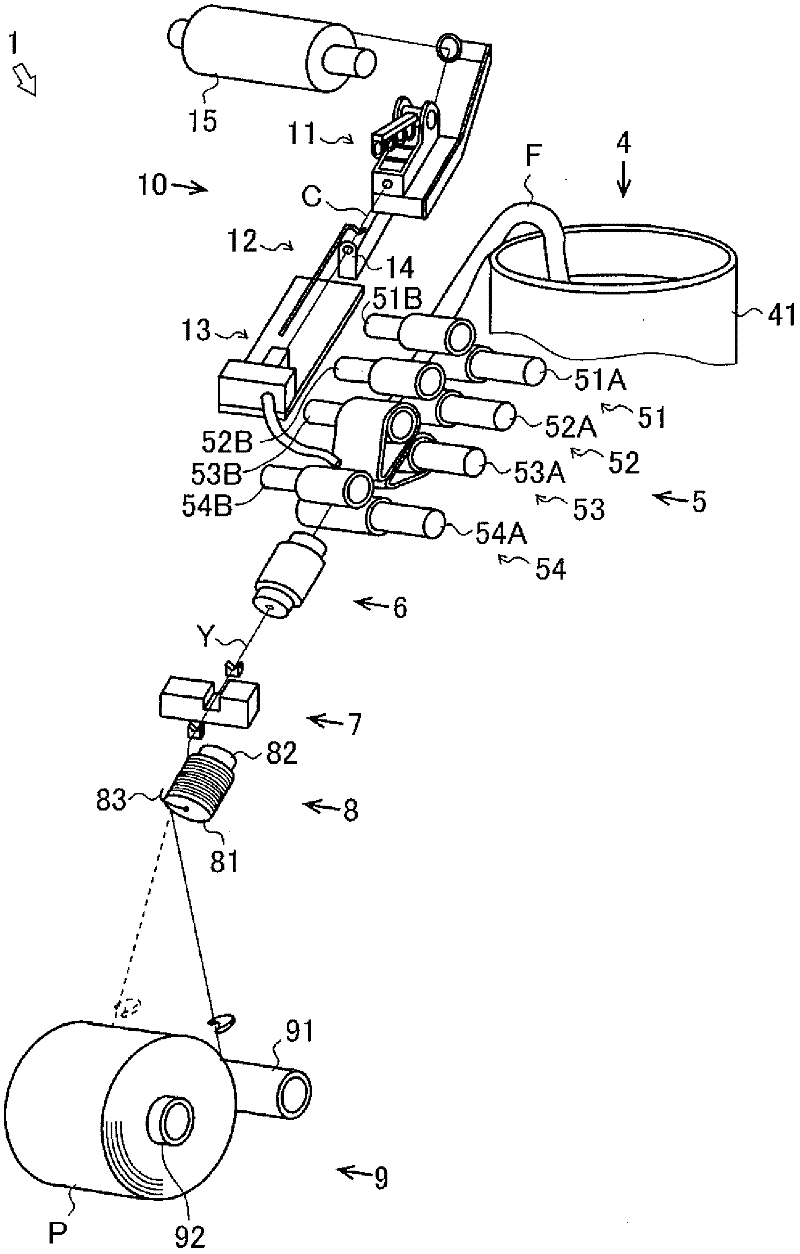

[0032] First, use figure 1 The overall structure of the spinning unit 1 will be described.

[0033] The spinning unit 1 is a spinning machine that manufactures a spun yarn Y from a core yarn C and a fiber bundle (hereinafter referred to as "sliver") to form a package P. The spinning unit 1 is mainly composed of a sliver supply unit 4 arranged along the conveying direction of the sliver F and the spinning yarn Y, a drafting device 5, an air spinning device 6, a yarn defect detection device 7, a tension stabilizing device 8 and a winding The device 9 constitutes. Furthermore, the spinning unit 1 is provided with a core yarn supply device 10 that supplies the core yarn C to the air spinning device 6 .

[0034] The sliver supply device 4 supplies the sliver F as a raw material of the spun yarn Y to the draft device 5 . The sliver supply device 4 is mainly composed of a sliver case 41 and a not-shown guide rail. The sliver F stored in the sliver housing 41 is guided by the cree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com