Method for arranging energy-saving oven pipes

An arrangement method and oven technology, applied in lining repair and other directions, can solve the problems of unstable ignition, uneven temperature, ignition danger, etc., and achieve the effects of improving the heating rate control accuracy, good temperature uniformity, and improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

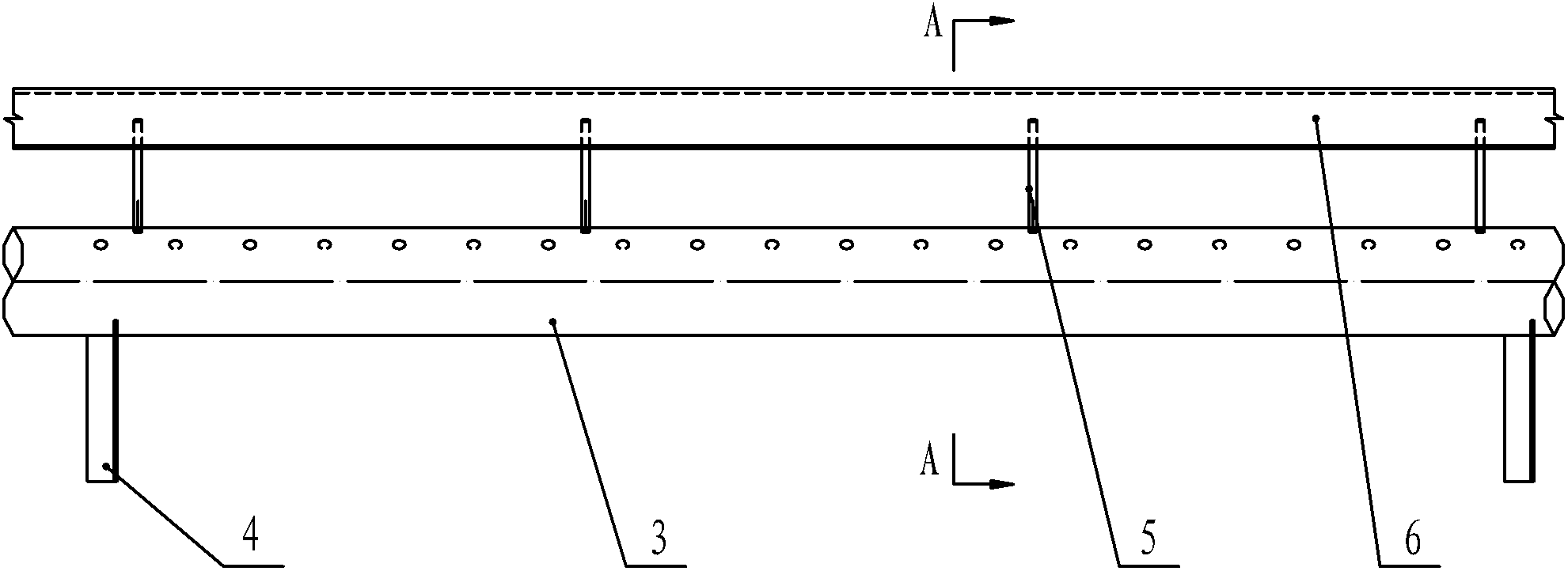

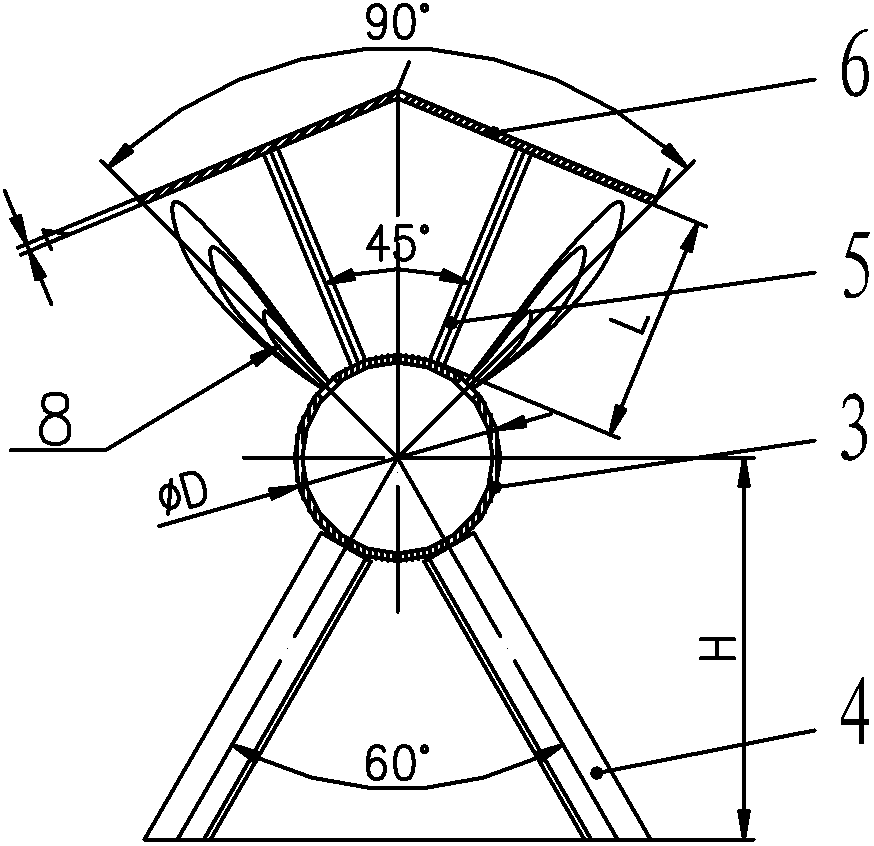

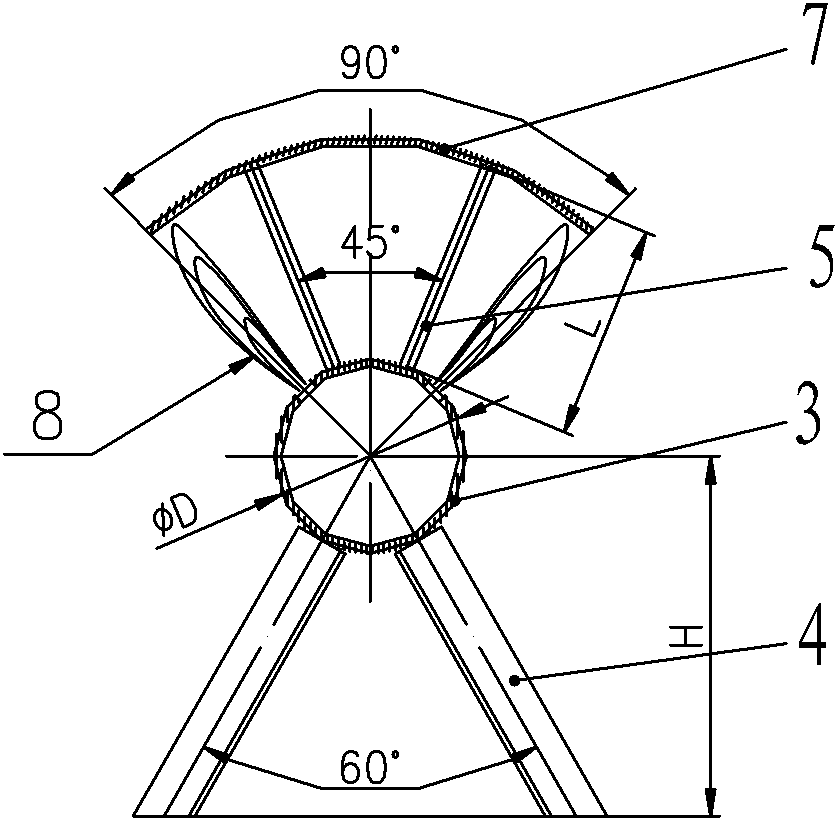

[0024] The design and layout of the new energy-saving oven tubes of the present invention, which can adapt to the large fluctuations in calorific value and pressure, will be described in detail below with reference to the accompanying drawings.

[0025] For the arrangement method of the energy-saving oven tube provided by the present invention, see Figure 5 , including the furnace tube installation process and laying process, as follows:

[0026] 1. Oven tube installation process:

[0027] When laying the cotton yarn 1, it is recommended to adopt the winding method, and to wind more cotton yarn at the position of the opening 2 of the oven tube. After winding and laying the cotton yarn 1 on the tube body of the oven tube 3, pour gasoline on the cotton yarn 1, and finally place the inverted V-shaped sheet cover 6 or the inverted U-shaped sheet cover 7 on the corresponding flame stabilizing device bracket of the oven tube 3 5 on.

[0028] When laying cotton yarn, the stable h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com