Screw mounting device

A technology for installing equipment and screws, applied in the field of screw installation equipment with anti-missing function, can solve problems such as potential safety hazards, operator injury, screw gun power on, etc., and achieve the effect of avoiding personal injury accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

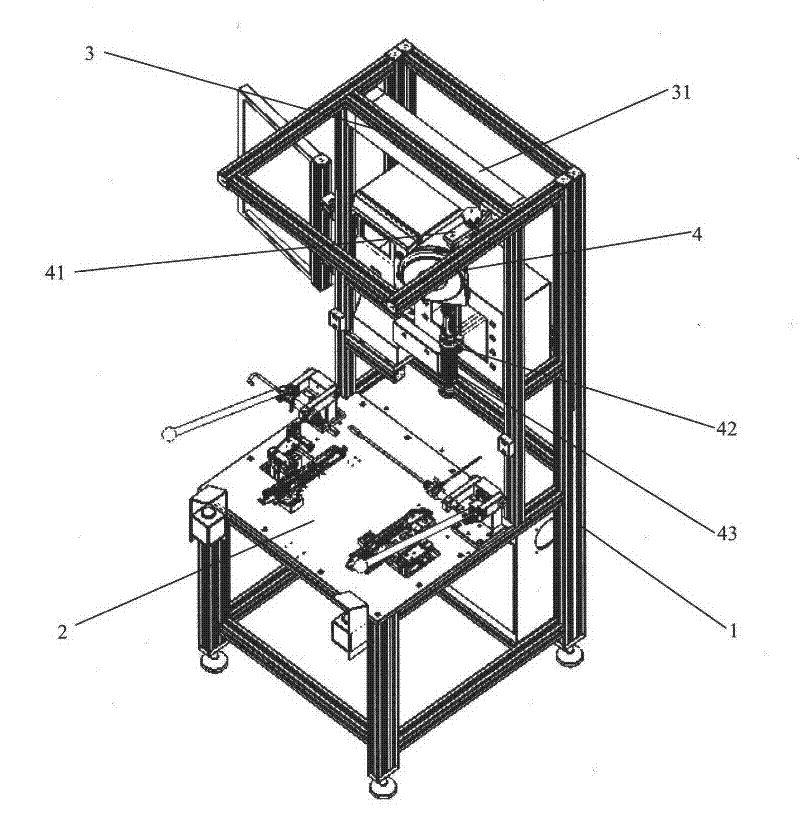

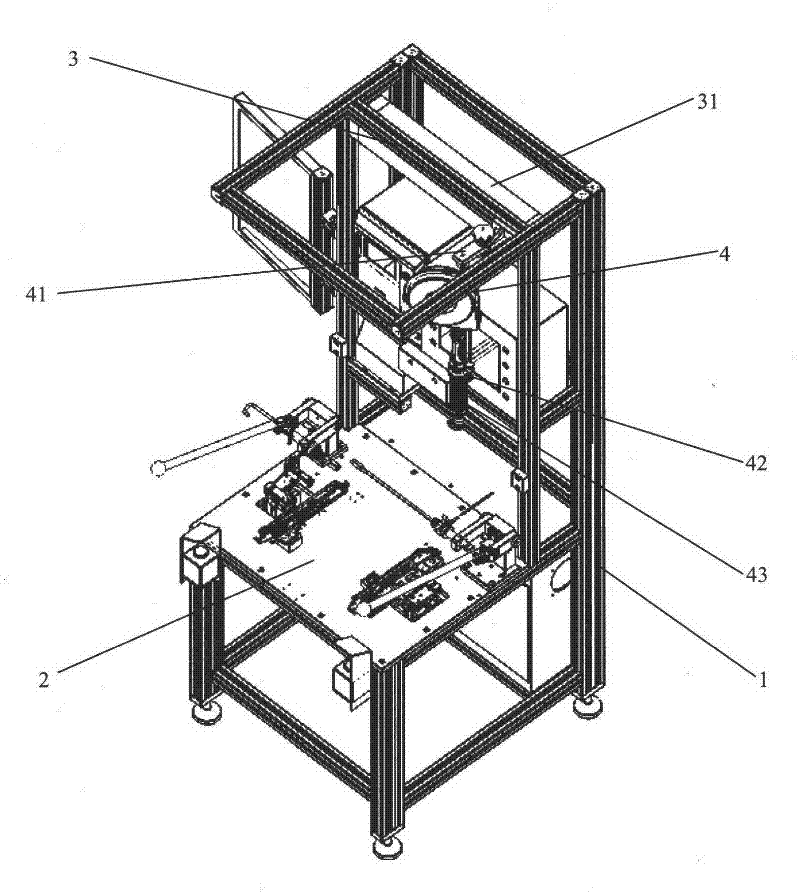

[0014] The present invention is further elaborated below by way of specific implementation: (as figure 1 )

[0015] A screw installation device provided in this embodiment includes a frame body 1, a workbench 2 is arranged on the lower part of the frame body, a plurality of track grooves 3 are arranged on the upper part of the frame body, and a screw gun 4 is arranged on one side of the track groove, and the track groove A laser sensor 31 is arranged on the screw gun, and a photosensitive sheet 41 paired with the laser sensor is arranged on the screw gun. The laser sensor on the track groove can slide along the track groove, a connecting part 42 is arranged between the screw gun and the track groove, the screw gun is fixed on the connecting part, and the connecting part can slide along the track groove. The screw gun includes a gun body 43, and the photosensitive sheet is arranged in the middle of the gun body.

[0016] A screw installation device provided in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com