Turbo machine electrical connection element

A turbine engine and electrical connection technology, which is applied in the direction of electrical components, parts of the connection device, connections, etc., can solve the problems of inability to remove molded parts surrounding the wires, and inability to withstand high temperatures, so as to prevent friction and wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

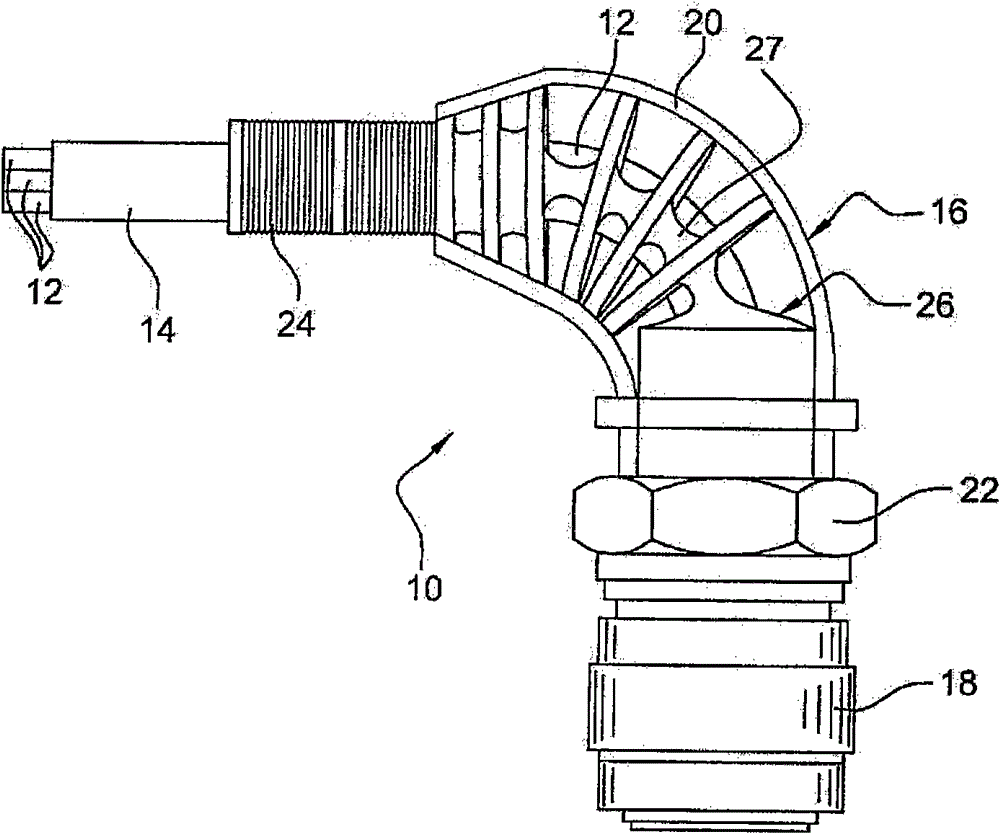

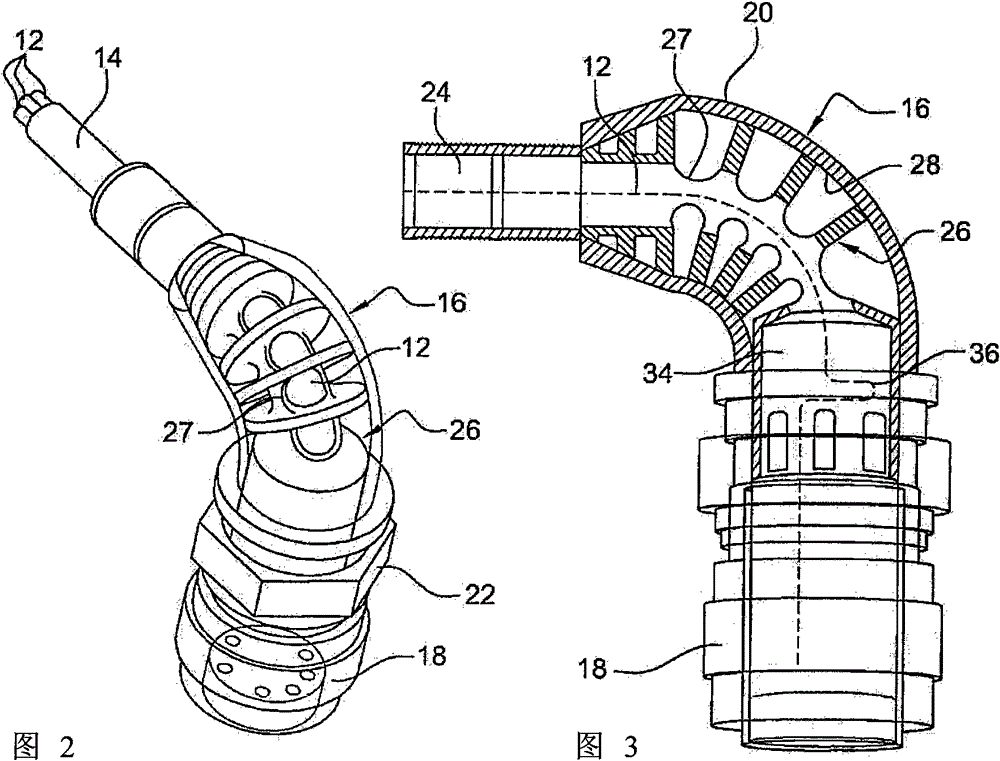

[0024] initial reference figure 1 , figure 1 Shown are the ends of an electrical connection element 10 having one or more conductors 12 for transmitting electrical signals, surrounded by a tubular protective structure 14, the ends of which are connected by coupling means 16 to connector 18.

[0025] The coupling device 16 includes a tubular connector 20 that surrounds the ends of the wires 12 that are electrically connected to the connector 18 .

[0026] In this example, the tubular connector 20 takes the form of a 90° elbow carrying at one end a nut 22 which is free to rotate and is threaded onto a corresponding part of the fitting 18 to secure the tubular connector 20 to connector 18.

[0027] An end of the tubular connector 20 away from the nut 22 has a fastener 24 to be fastened to an end of the tubular structure 14 . The tubular connector 20 is rigid and made of metal.

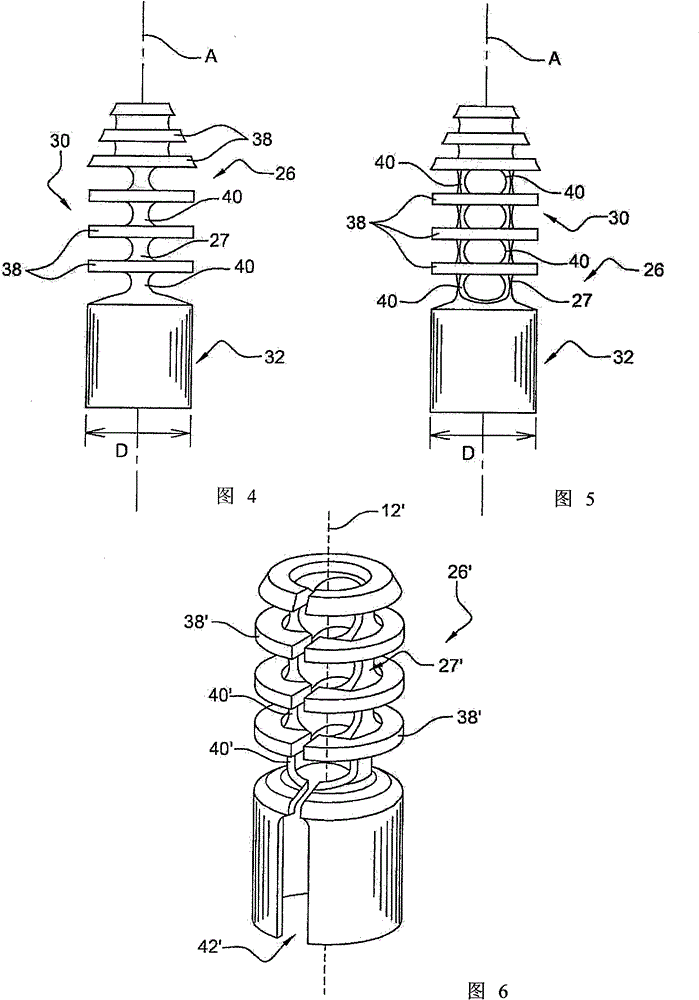

[0028] According to the invention, an insert 26 for protecting the wire 12 from wear is accommoda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com