washing dry scrubbing machine

A technology for washing, drying and scrubbing machines, which is applied in the direction of cleaning machinery, cleaning carpets, cleaning floors, etc., and can solve problems such as inaccurate adjustment, poor operational flexibility, and changing the effect of detergents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

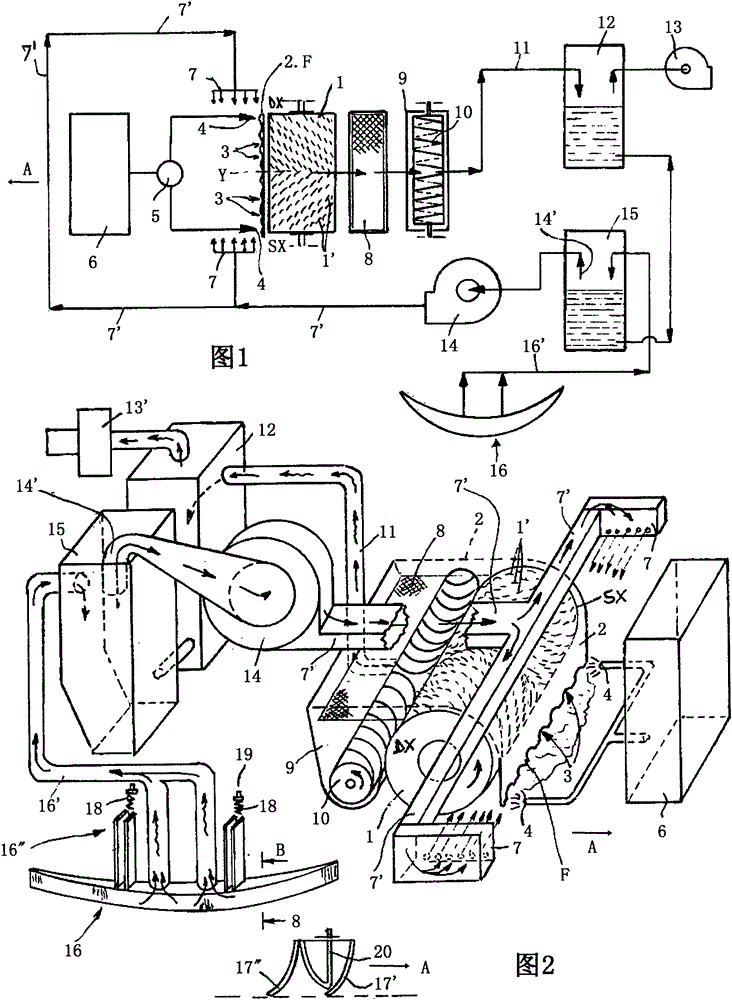

[0024] With reference to the accompanying drawings, according to the invention, a washing-drying scrubbing machine has an accommodating and targeted and guiding orientation system for the front side flow of the wash mixture directed towards the washing trajectory along which said washing-drying scrubbing machine travels, The washing-drying scrubbing machine comprises a structure (2) housing a rotating roller brush (1) arranged on the front side, the outer peripheral surface of which is covered with pointed bristles (1') Covering, said bristles (1') face upwards and converge near the front part of the rotating roller brush (1) from the L and R end edges towards its central axis of symmetry (Y), facing the operating area, the rotating roller brush (1 ) is arranged facing the lower part of the structure (2) on which a tab (F) is arranged comprising a number of small aligned openings (3) oriented and facing the floor to be washed.

[0025] On the side of the housing (2) facing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com