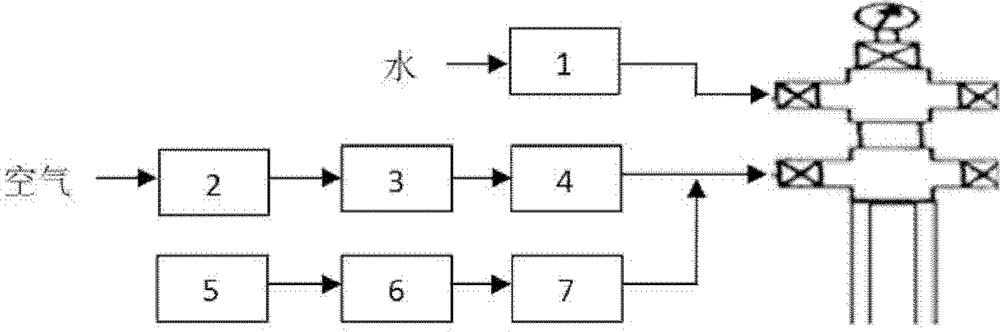

Multi-element thermal fluid production process for heavy oil reservoir and thermal recovery process

A technology of multi-component thermal fluid and thermal recovery technology, which is applied in the direction of mining fluid, earthwork drilling, isolation devices, etc., can solve problems such as the inability to adjust the composition of multiple thermal fluids, and the effect cannot be guaranteed, so as to reduce supporting equipment and reduce occupation The effect of increasing the floor area and increasing the amount of steam absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings, so that those skilled in the art can practice the present invention. It is to be understood that other embodiments may be utilized, and that appropriate changes may be made without departing from the spirit or scope of the invention. To avoid detail not necessary to enable those skilled in the art to practice the invention, the description may omit certain information known to those skilled in the art. Accordingly, the following detailed description should not be taken in a limiting sense, and the scope of the present invention is defined only by the appended claims.

[0025] The general principle of the present invention is explained below about a thermal recovery well of a certain offshore heavy oil reservoir in Bohai Bay as an example, but it should be noted that the present invention is by no means limited to thermal recovery wells of heavy oil reservoirs i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com