Pattern making method of suit sleeve

A sleeve and suit technology, applied in the field of clothing design and production, can solve problems such as errors, and achieve the effect of simplifying design procedures, rational design, and saving proportional calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

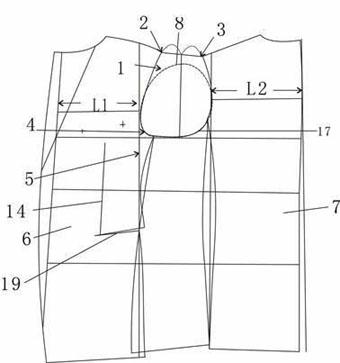

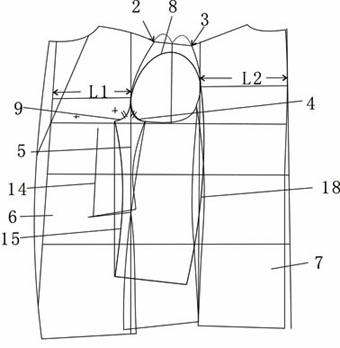

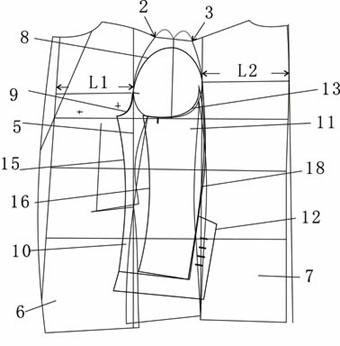

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] The plate-making method of suit sleeve of the present invention, process comprises: (1) measure the net bust size of human body, determine shrinking amount according to design requirement. ⑵ Measure the size of the week including the arm; that is, the human body stands naturally, and the horizontal circumference of the armpit is measured for a week. (3) Measure the chest width L1 and back width L2 of the human body. ⑷ such as figure 1 Shown, make the plan view of front garment panel 6 and rear garment panel 7, determine the depth and the width of armhole. ⑸ Align front shoulder point 2 and back shoulder point 3 with a serpentine ruler to measure the circumference, so that the two ends intersect on the vertical center line. After the intersection, the front and rear garment parts are in a state of overlapping, and the connecting parts of the front and rear garm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com