Winding overhang support of an electrical machine

A technology for winding ends and supporting devices, applied in the directions of electromechanical devices, windings, electric components, etc., can solve problems such as cooling interference, and achieve the effect of improving cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

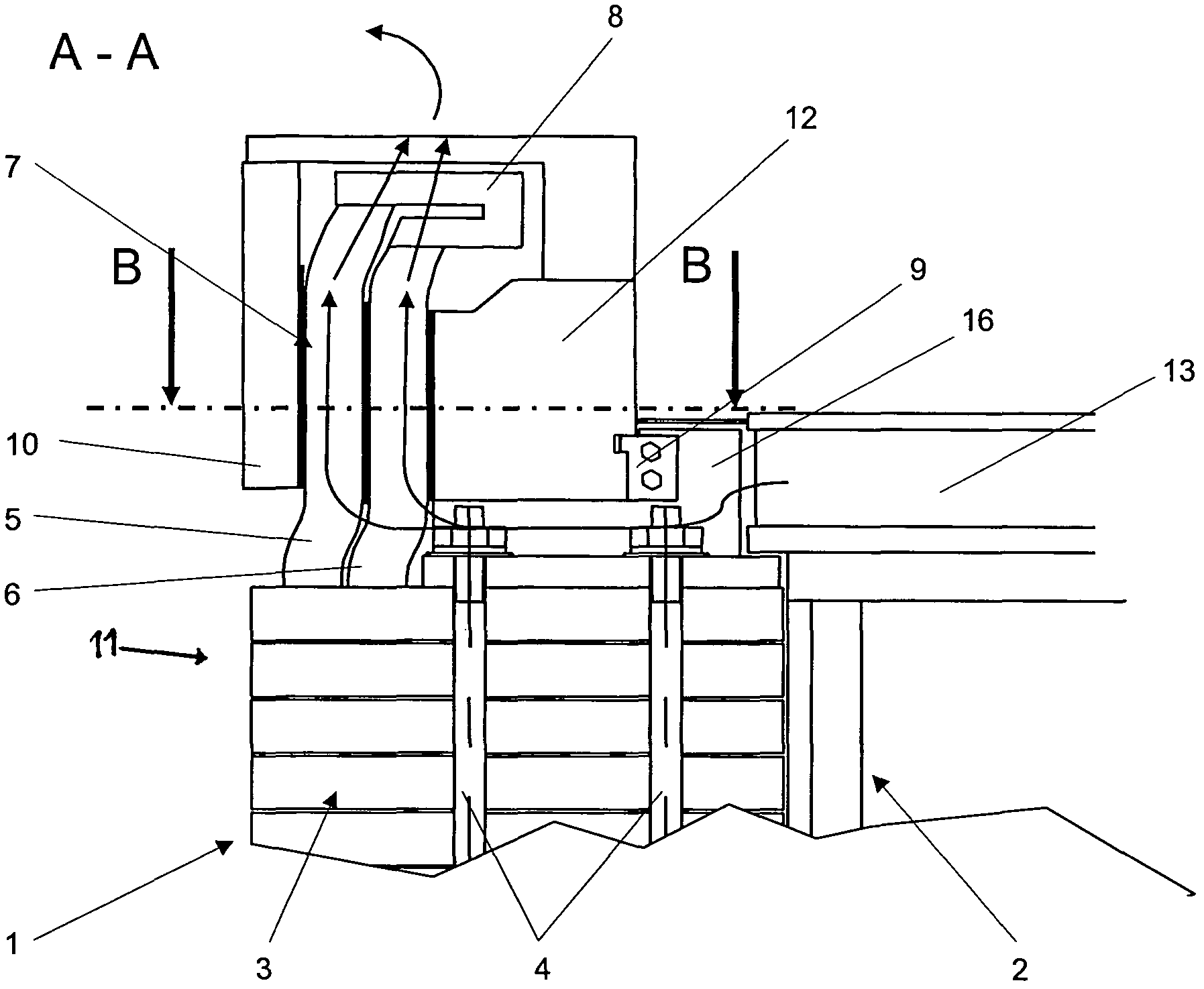

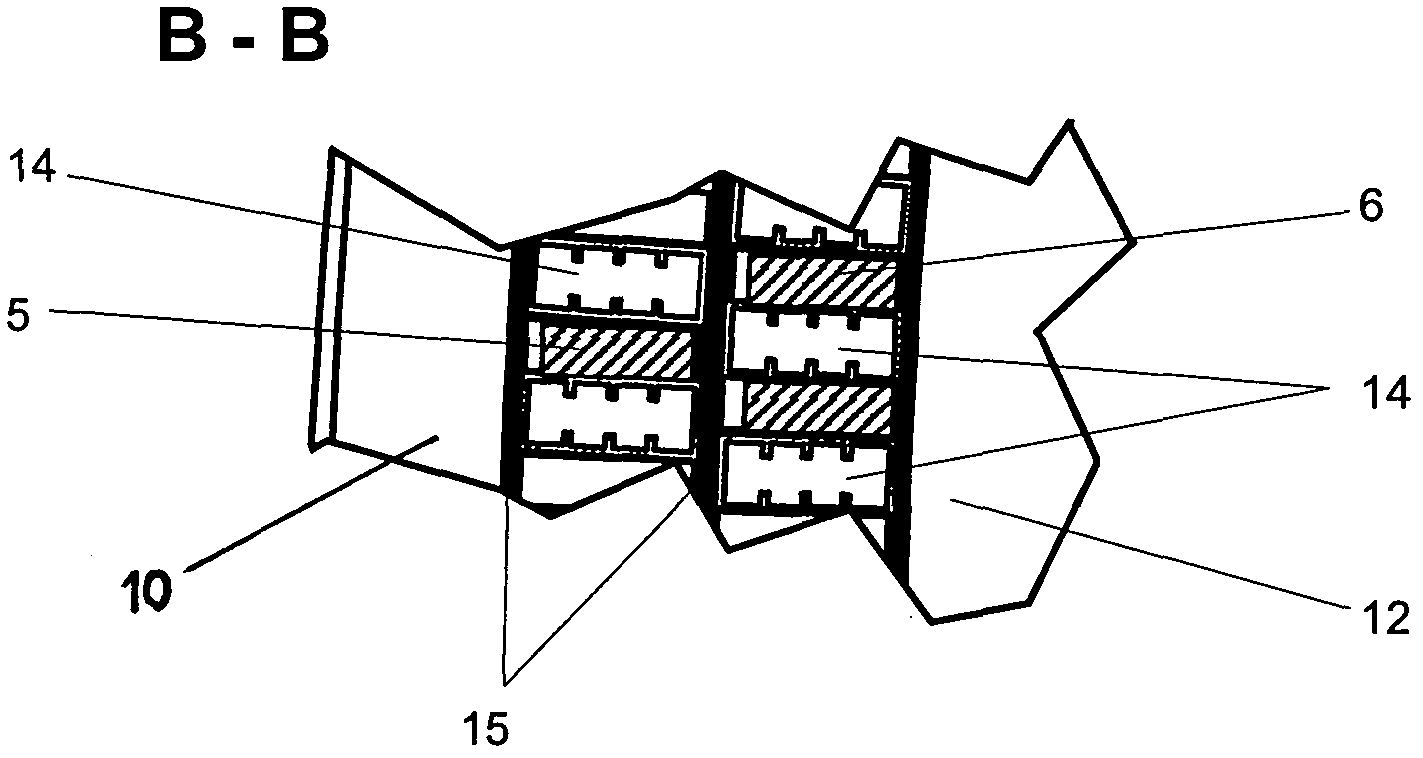

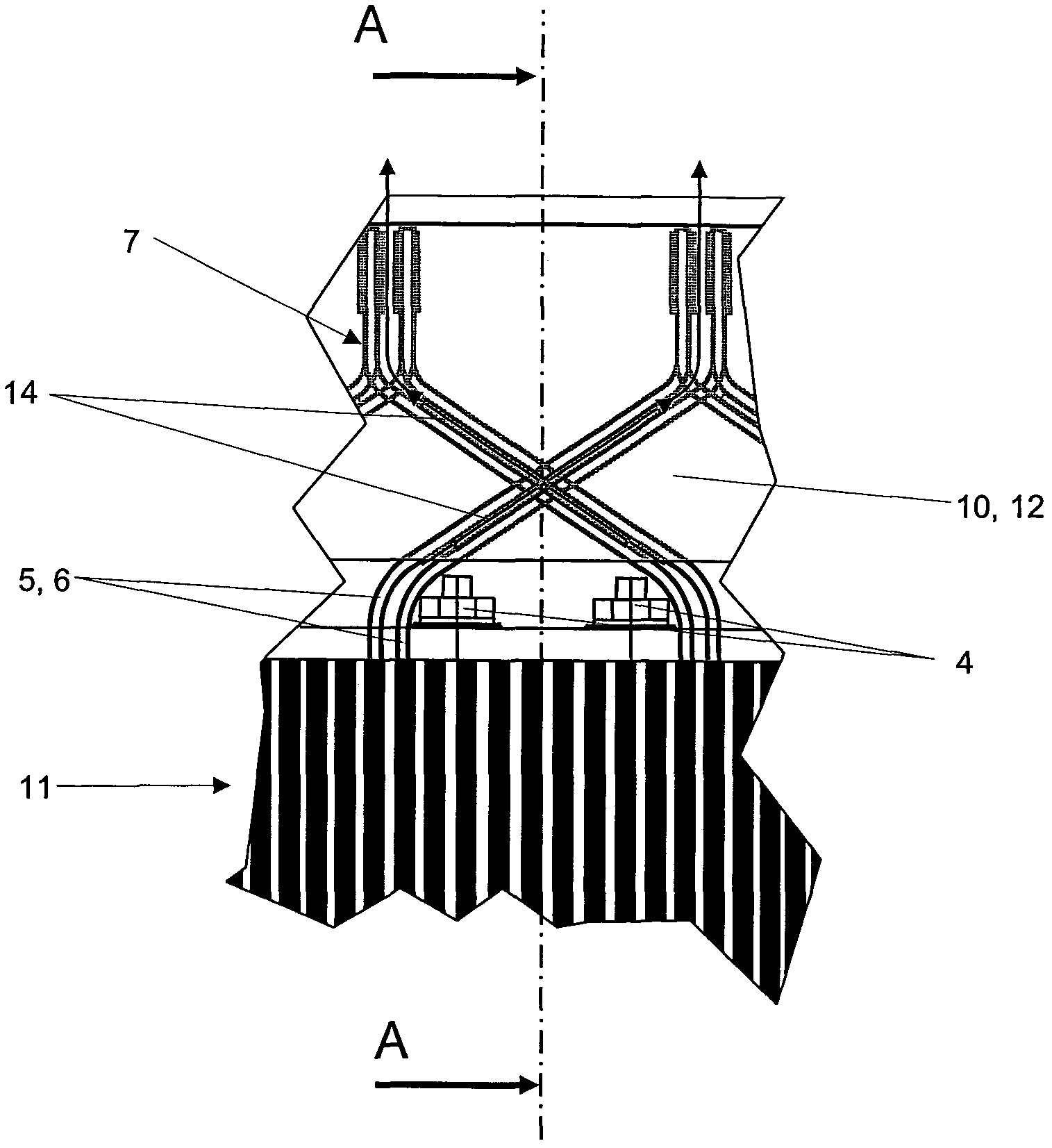

[0028] Motors such as hydroelectric generators are figure 1 The rotor 1 shown in FIG. 2 comprises spokes 2 on which a laminated core 3 of the rotor 1 is arranged in a known manner. In this case, the laminated core 3 is held together by well-known hold-down screws 4 . In this case, the spokes 2 and the laminated core 3 form the rotor body 11 of the rotor 1 . Slots are arranged in the radially outer region of the laminated core 3 , not shown here, into which slots the insulated winding bars (here upper bar 5 and lower bar 6 ) are inserted and held radially by means of slot wedges. . Such arrangements are sufficiently known and therefore not discussed further here. The winding bars 5 , 6 protrude axially from the laminated core 3 on both sides and form so-called winding ends 7 outside the laminated core 3 . As is well known, the winding bars 5 , 6 are arranged obliquely relative to the axial direction in the region of the winding head 7 , wherein the upper bar 5 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com