pneumatic tire

A pneumatic tire, tire circumferential technology, applied in tire parts, tire tread/tread pattern, rolling resistance optimization, etc., to achieve good rolling resistance and wet performance, reduce passing sound, maintain rolling resistance and wet performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

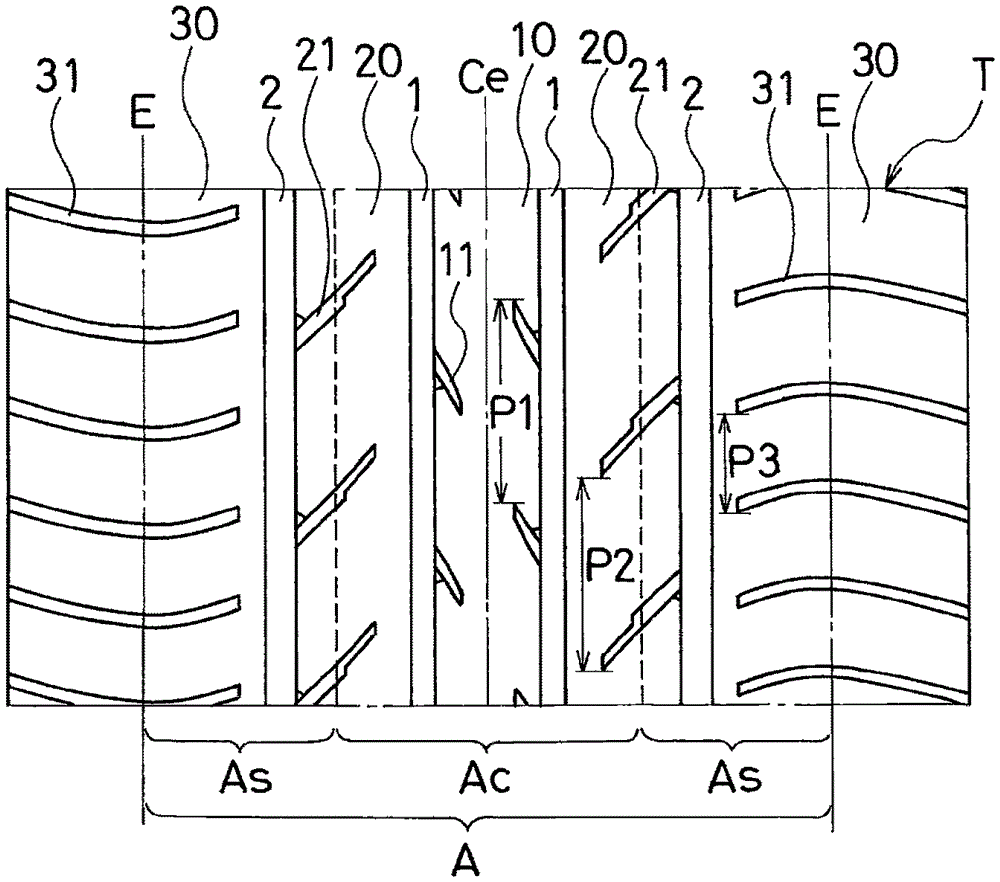

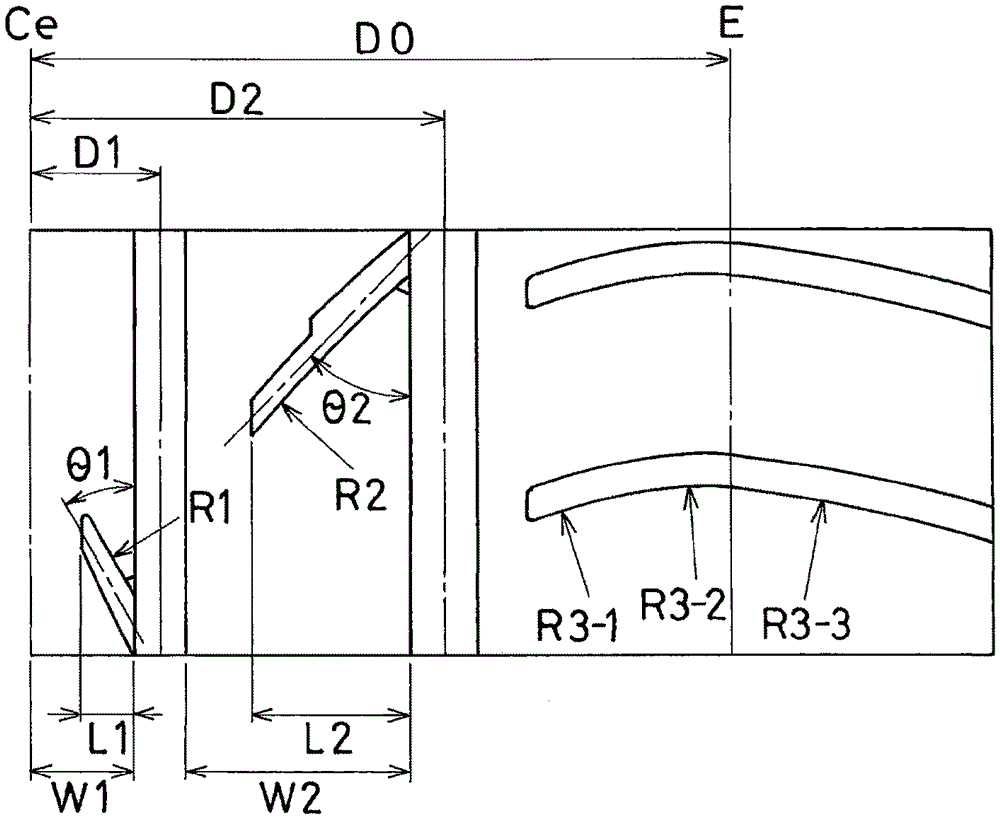

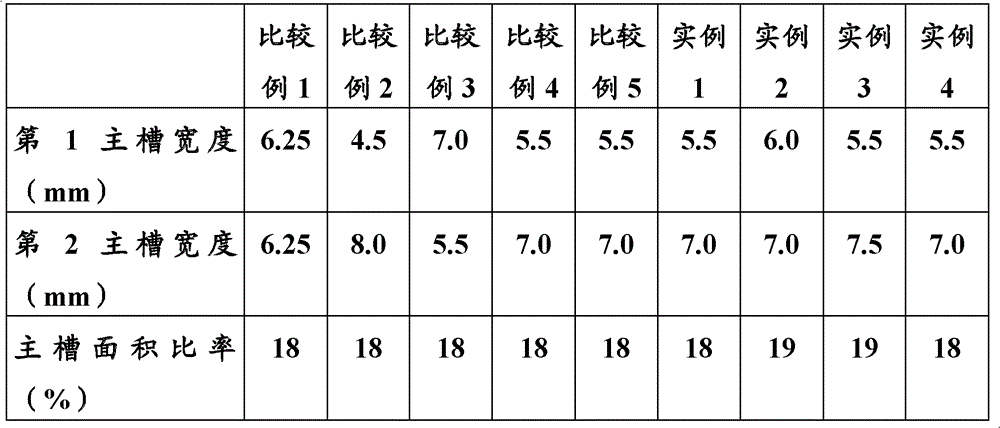

[0039] Pneumatic tires of Comparative Examples 1 to 5 and Examples 1 to 4 were produced. The tire size was 195 / 65R1591H. A pair of first main grooves located on both sides of the central position and extending along the tire circumferential direction were provided on the tread portion, and a pair of first main grooves located on the opposite sides of the tread portion were provided. The first main groove is closer to the shoulder side and a pair of second main grooves extending along the tire circumferential direction. A central rib pattern is divided between the pair of first main grooves. Between the first main groove and the second main groove The middle rib is divided into the middle rib, and the outer side of the second main groove is divided into the shoulder rib. Among them, a plurality of tread grooves are respectively formed on the central rib, the middle rib and the shoulder rib. These The structure of the sipes varies.

[0040] The tires of Comparative Examples 1-4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com