Expansion valve

An expansion valve and valve core technology, applied in the field of expansion valves, can solve problems such as load application, refrigerant flow drop, abnormal noise, etc., and achieve the effect of suppressing vibration and reducing passing sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

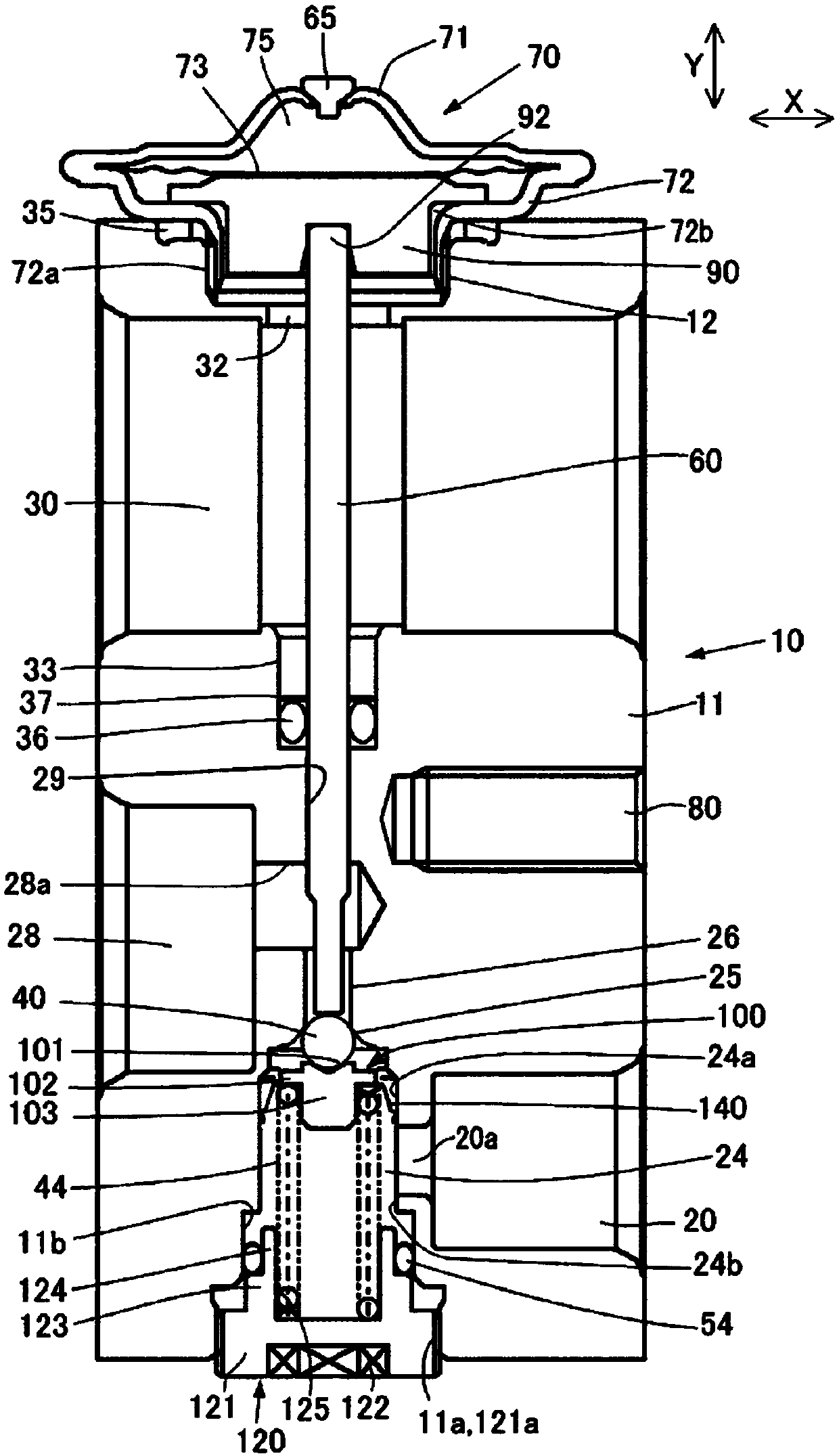

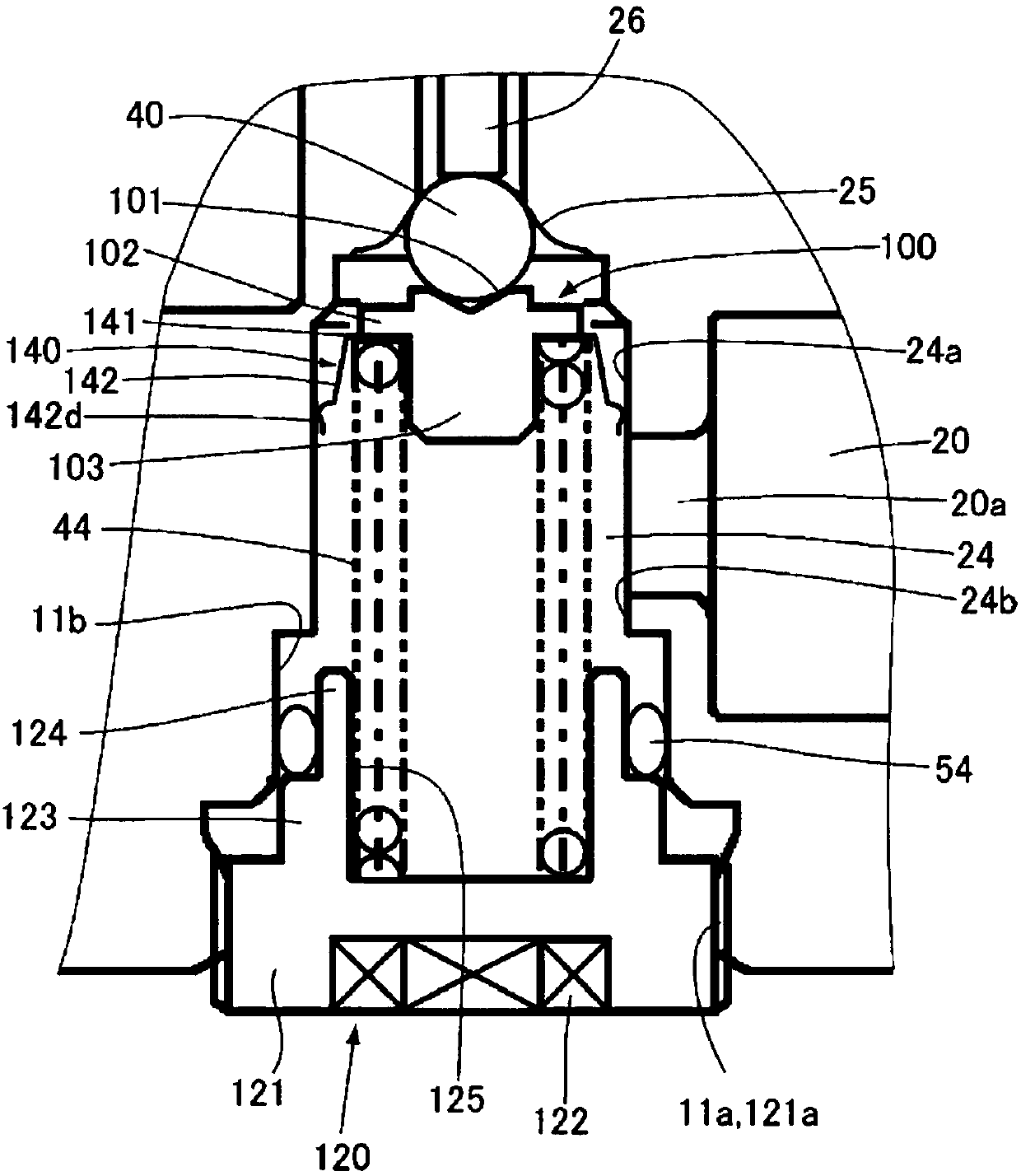

[0034] figure 1 It is a longitudinal sectional view showing the first embodiment of the expansion valve of the present invention. figure 2 It is a longitudinal sectional view of main parts of the expansion valve of the first embodiment.

[0035] like figure 1 As shown, the expansion valve 10 includes a valve body 11 , a power element 70 , a valve body 40 , a valve stem 60 , an O-ring 36 , a support member 100 , an anti-vibration spring 140 , a coil spring 44 , and an adjustment screw 120 .

[0036] The valve main body 11 is made of aluminum alloy, for example, and can be figure 1 The X direction is the extrusion direction, which is obtained by extruding aluminum alloy, etc. and applying mechanical processing to it. The valve main body 11 has a power element mounting part 12 which is an internal thread formed on the upper surface and is screwed with the external thread 72a of the power element 70 to fix it, an inlet port 20 through which high-pressure refrigerant is intr...

no. 2 example

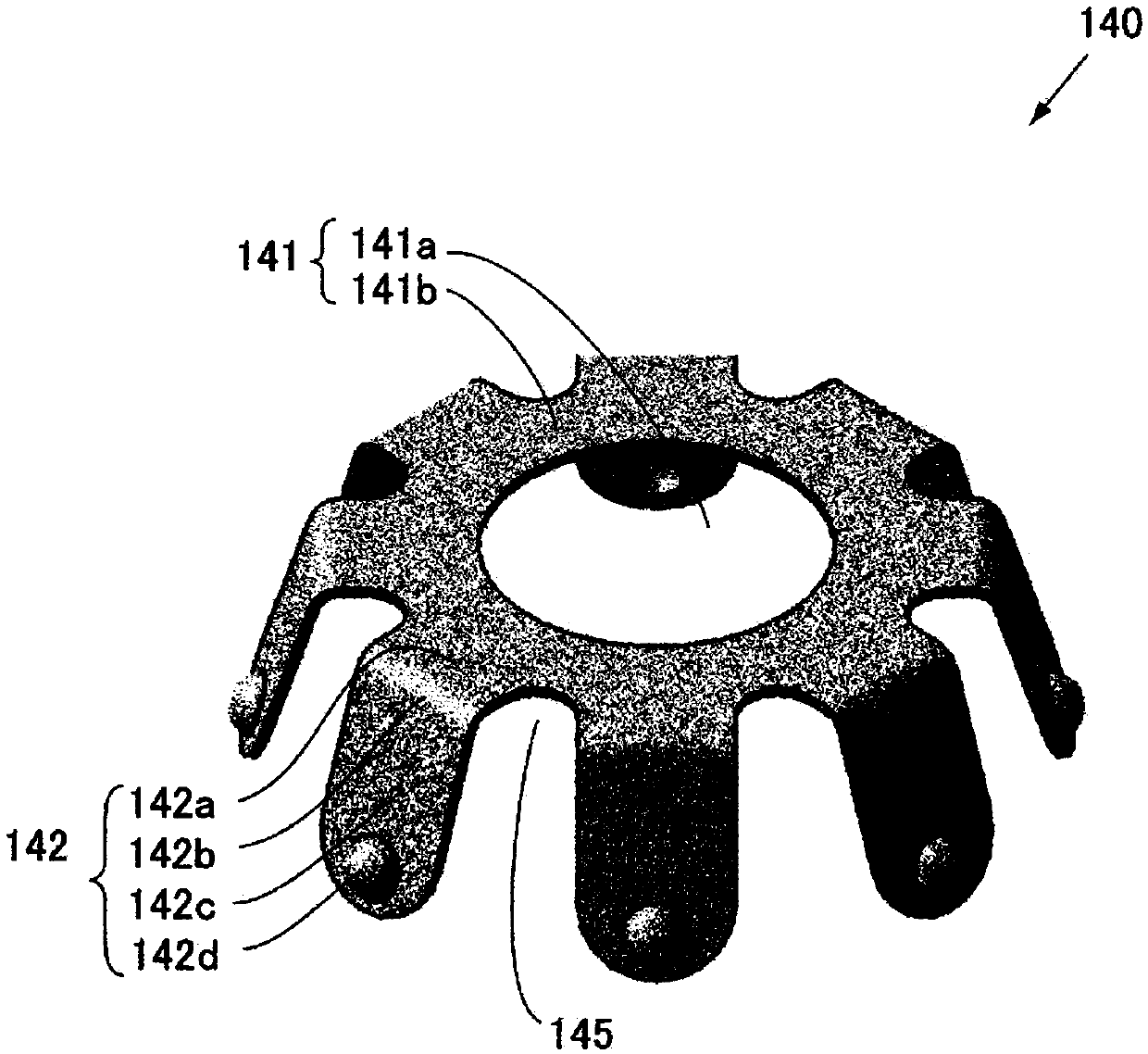

[0061] Image 6 It is a plan view showing the anti-vibration spring of the second embodiment. The second embodiment is a structure in which the anti-vibration spring 140 of the first embodiment is replaced by the anti-vibration spring 240 . Other than that, it is the same as the structure shown in the first embodiment, so further description of the common parts will be omitted.

[0062] The anti-vibration spring 240 includes a base portion 241 and a leg portion 242 . The anti-vibration spring 240 can be obtained by stamping an elastic plate material such as stainless steel and its alloy.

[0063] The base portion 241 is an annular plate-shaped member forming the upper portion of the anti-vibration spring 240, and has the same mounting hole 141a as in the first embodiment in the center.

[0064] A plurality of leg portions 242 extend from the outer peripheral side of the base portion 241 in a direction perpendicular to a tangent to the circumferential direction, that is, exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com