Speed regulating mechanism of boarding machine

A technology of a speed regulating mechanism and a setting machine, which is applied to heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of high manufacturing cost, inconvenient installation and maintenance, complicated transmission mechanism, etc. Easy to install and reduce the effect of the transmission mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

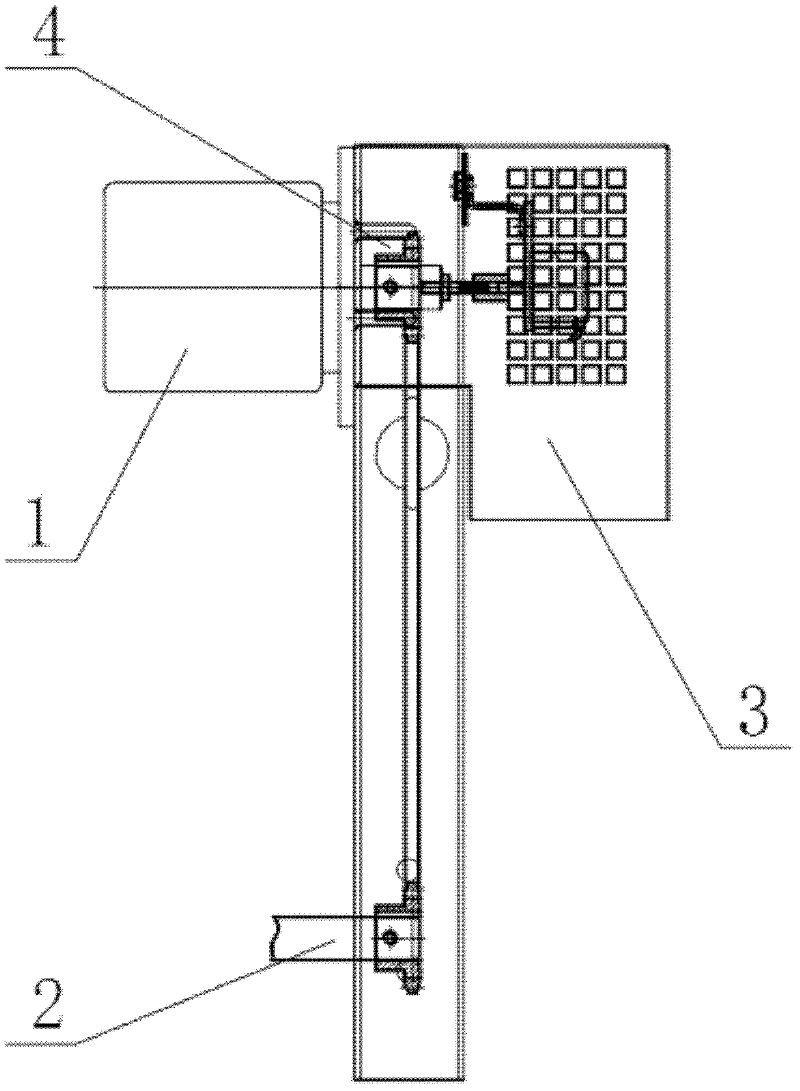

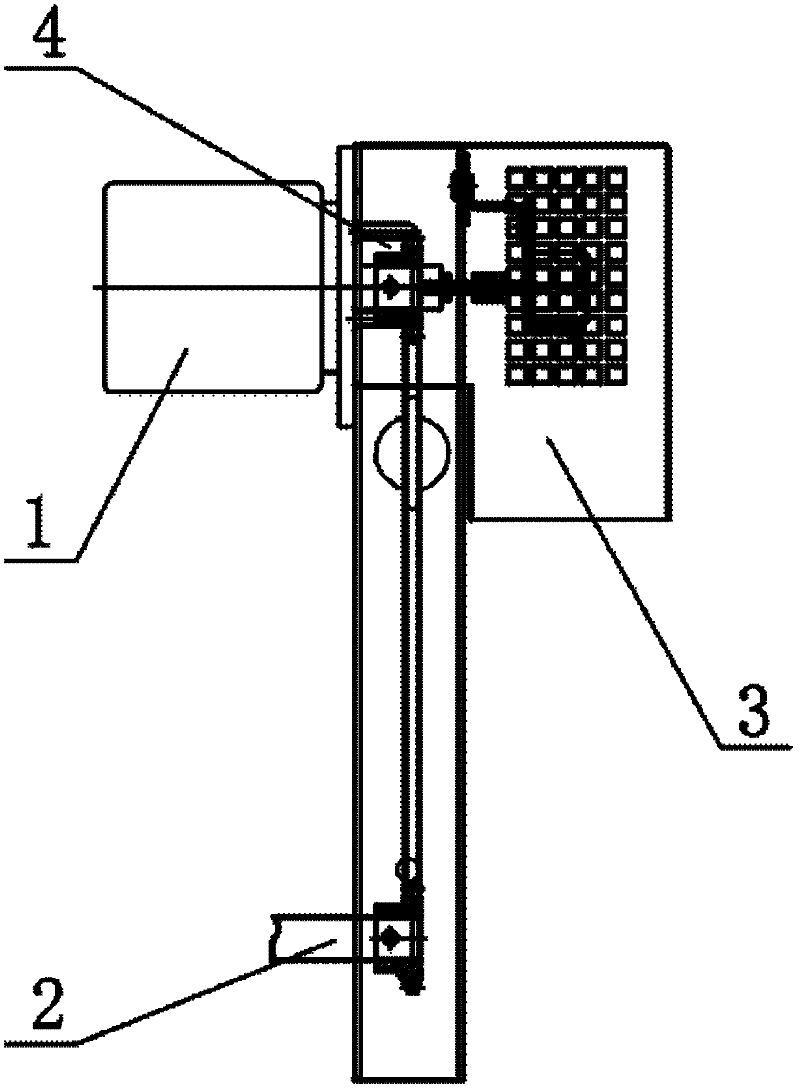

[0009] Such as figure 1 A speed regulating mechanism of a shaping machine is shown, comprising a motor 1, a screw mandrel 2 and an encoder 3, the motor 1 makes its output shaft speed reach the rated operating speed through a speed change mechanism 4, and the output shaft is provided with a sprocket 5 The screw mandrel 2 is driven by a sprocket transmission mechanism with constant speed ratio, and at the same time, the output shaft is directly connected to the encoder 3, and the encoder 3 adjusts the speed of the motor 1 according to the actual speed of the output shaft to control the speed of the screw mandrel 2.

[0010] The invention reduces the output speed of the motor to the working speed through the deceleration mechanism, and directly feeds back the speed information to the encoder, and adjusts the working speed of the screw rod through the encoder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com