Operation platform for floating-rope type abalone raising net cage and operation method of operation platform

A technology of operation platform and net cage, which is applied in fish farming, application, animal husbandry, etc., can solve the problems of inconvenience, difficulty, easy deformation, drift, etc., and achieve the effects of increasing breeding benefits, saving labor costs, and simplifying farming operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

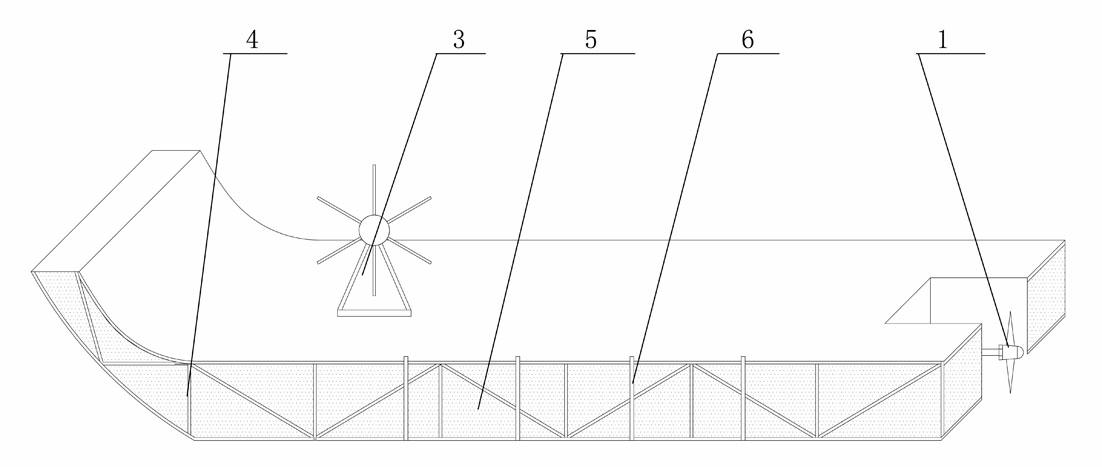

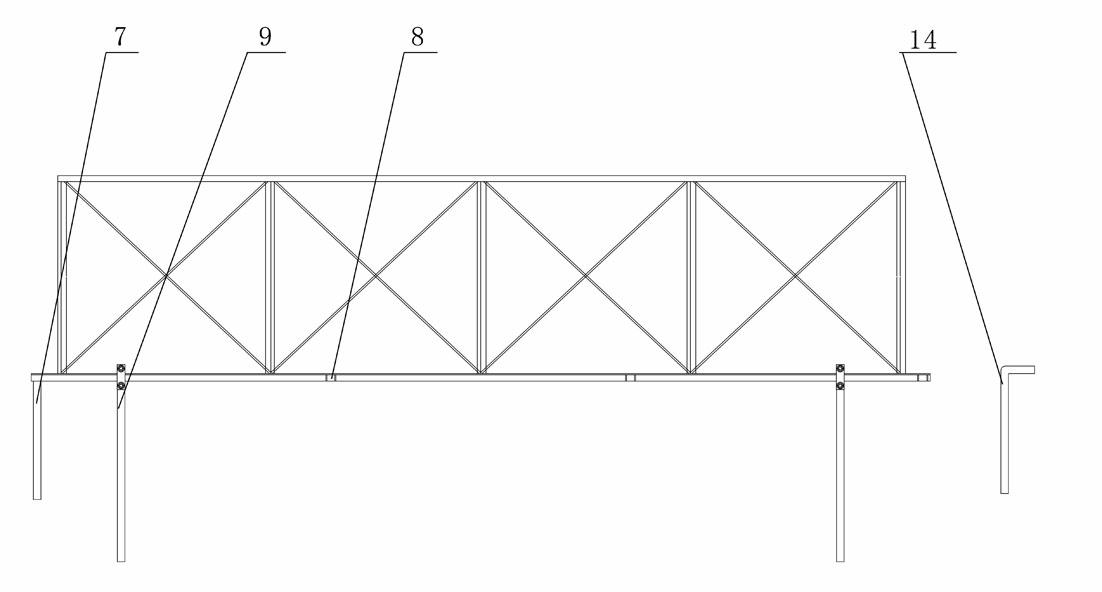

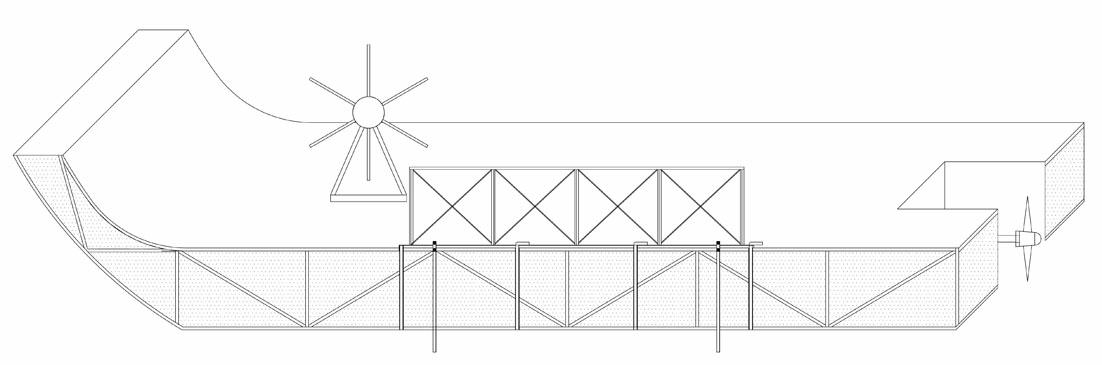

[0025] A kind of operation platform and operation method thereof for the floating rope type raising abalone net cage described in the present invention, such as figure 1 , 2 As shown in . The rigid frame structure 4 is welded into a rigid frame structure 4, and the foam plastic 5 wrapped by an anti-seepage plastic film is filled inside, and two decks are laid on it; the floating raft ship, each side of the ship's side rigid frame, is welded at intervals according to the requirements. Zinc pipe, as the sleeve pipe 6 on the movable shipboard base, the upper end of the sleeve pipe is higher than a certain distance from the deck of the floating raft, so it is advisable that the rotating operation of the movable shipside 2 will not be affected by the floating balls on the ship deck and the sea. The movable ship's side 2 is made of rigid material (steel or hard plastic material) into a truss structure, the bottom surface of which is a plane rigid frame with a certain width, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com