Active airflow field controlled plate surface cleaning device

A technology of cleaning device and airflow field, applied in the direction of metal rolling, manufacturing tools, metal rolling, etc., can solve the problem that the suction method cannot be solved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

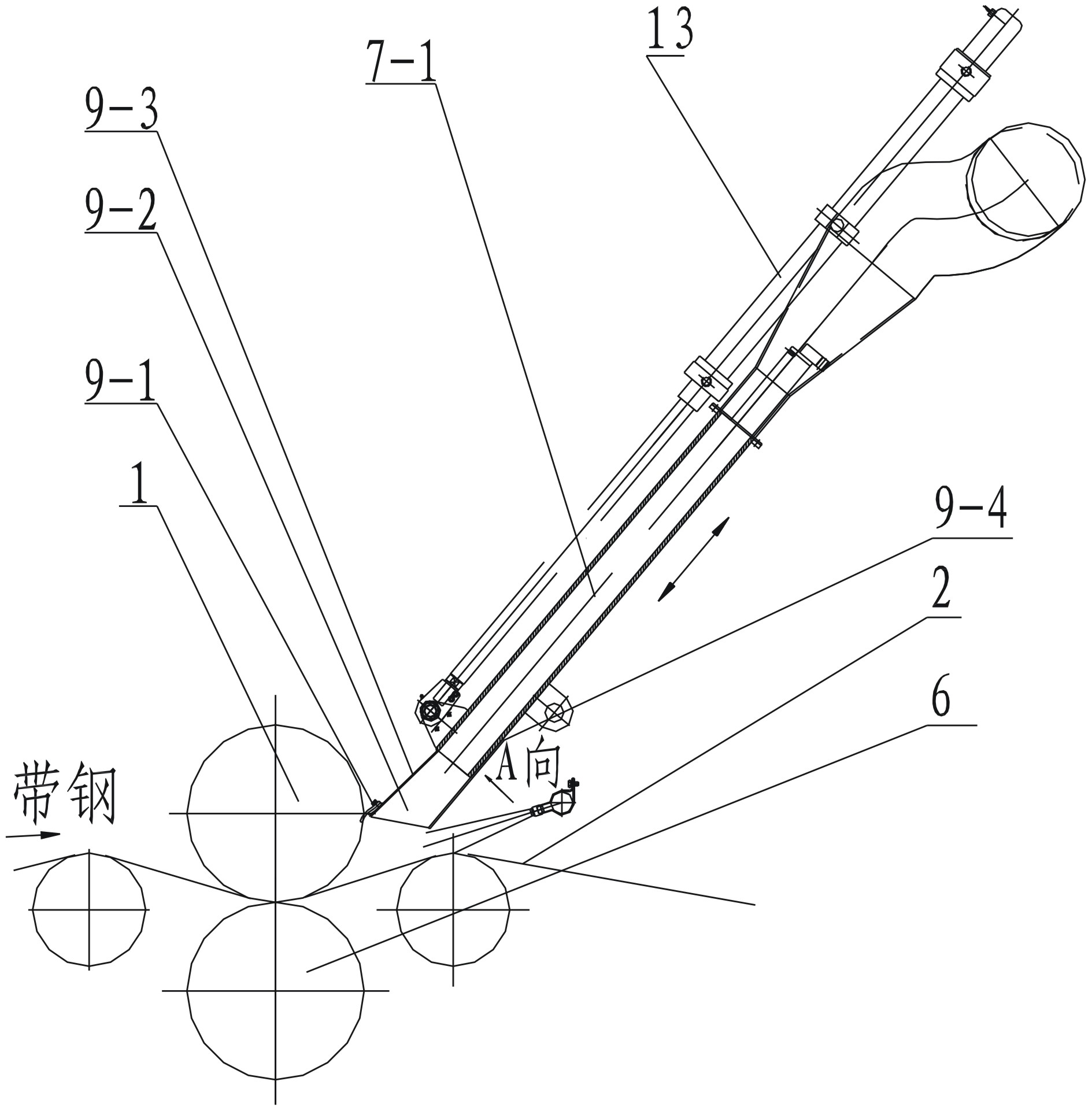

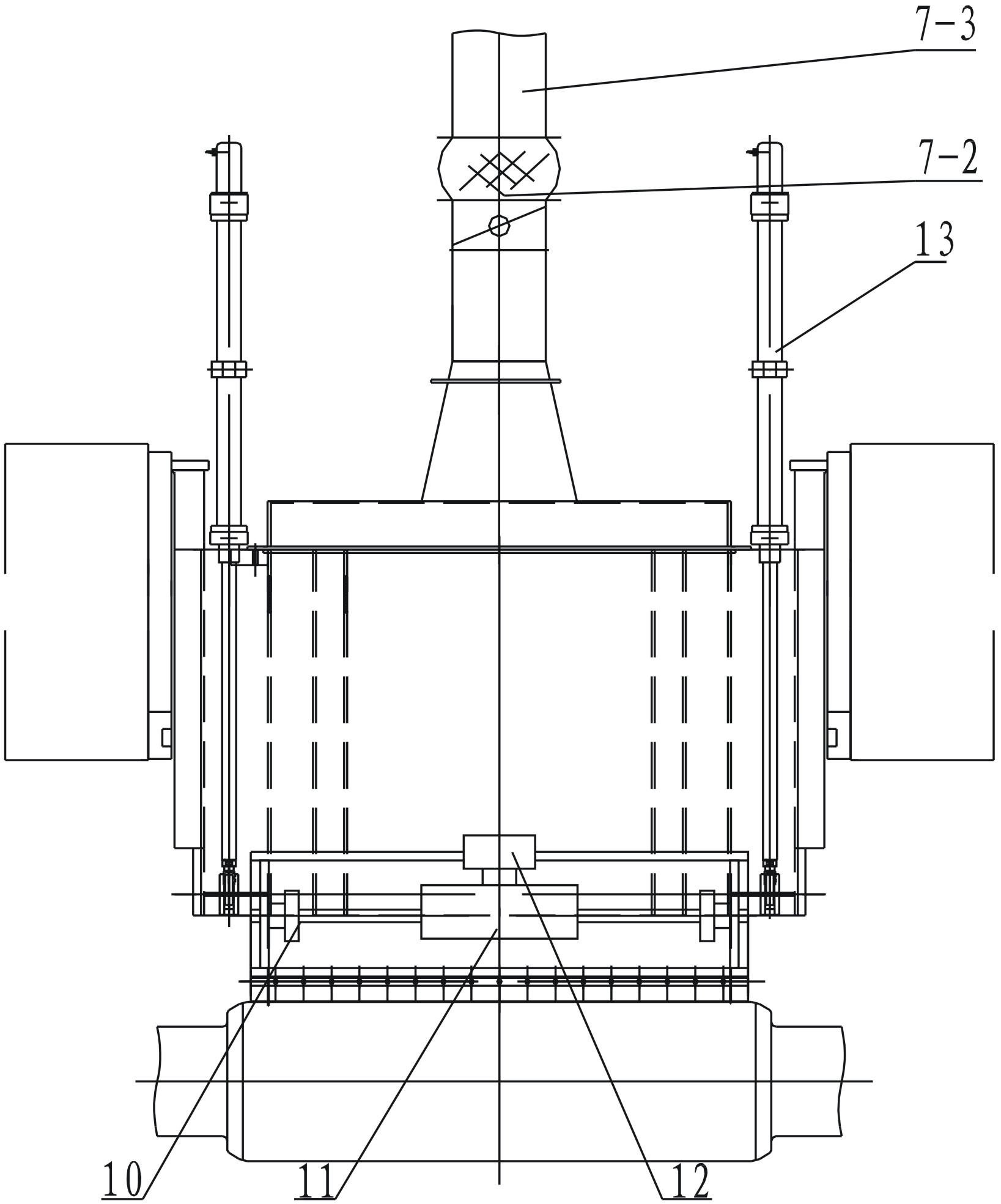

[0028] see Figure 1-5 : the active air flow field control type plate surface cleaning device implemented by the present invention is located above the strip steel at the temper machine outlet, and the leveling dust on the strip upper surface and the upper work roll area is removed; the active air flow field control type plate The surface cleaning device is located at the exit of the tempering machine, and mainly includes a dust purging device 8, a roll dynamic seal 9-1, a negative pressure suction device 7 and a dust collection device 9.

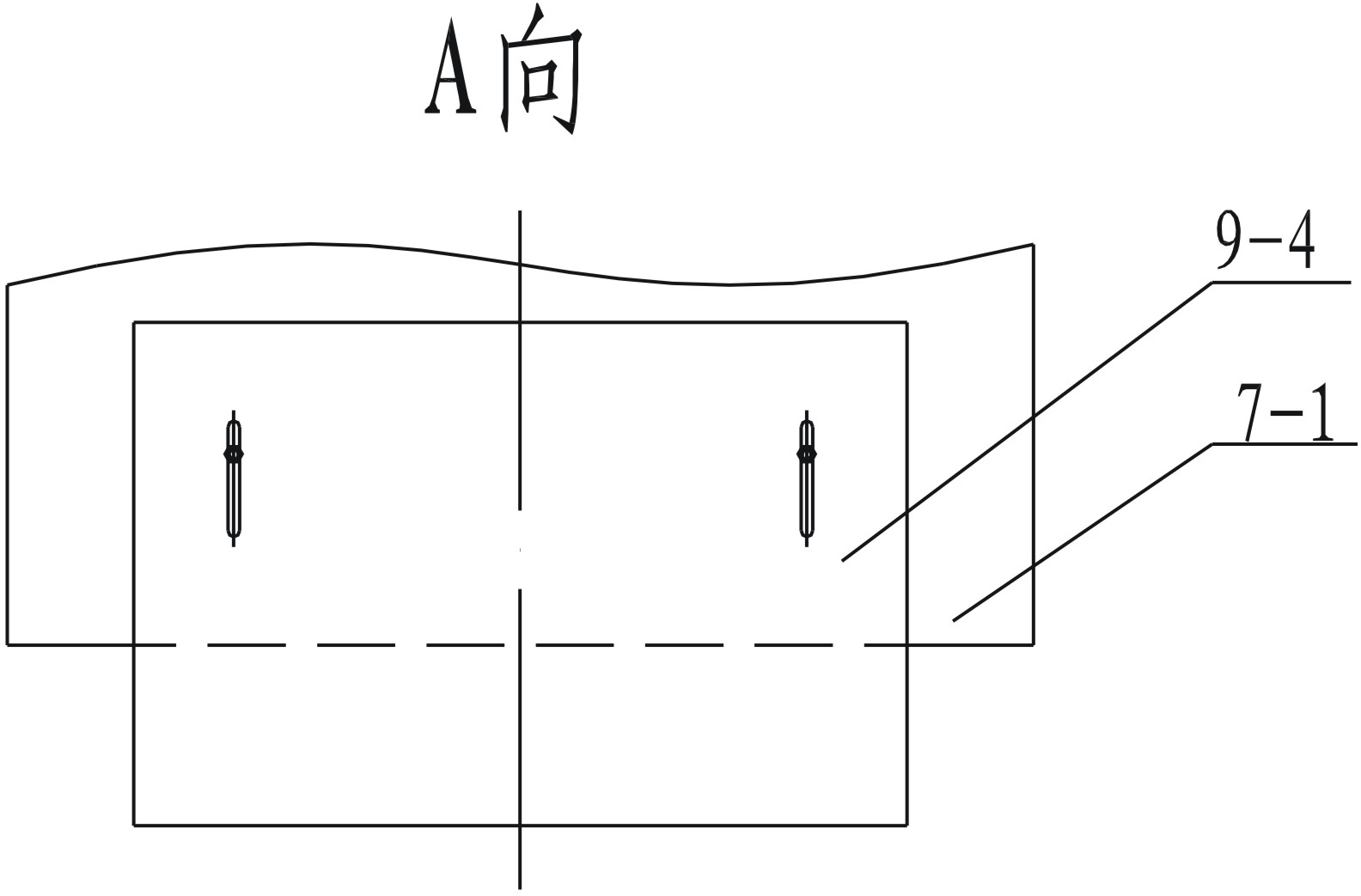

[0029] The structural diagram of the dynamic seal of the roll, the negative pressure suction device and the dust collection device is as follows: Figure 1-3 shown.

[0030] The high-temperature and wear-resistant roll dynamic seal 9-1 is arranged between the dust collection device 9 and the roll, and forms a seal in dynamic contact with the roll. The roll dynamic seal 9-1 is a rubber pad.

[0031] The dust collection device 9 includes a...

Embodiment 2

[0037] see Figure 6 and 7 : The active air field control type plate surface cleaning device applied to wet leveling implemented by the present invention is located above the strip steel at the temper mill outlet, mainly including blowing device 9, collecting device 10, negative pressure suction device 8, roll dynamic Seal 10-1; during the tempering process, the purging device 9 sprays compressed air to the entrance side of the tempering machine, and seals the leveling liquid accumulated at the entrance roll gap on the entrance side of the tempering machine; the negative pressure suction device 8 And the collection device 10 realizes the airflow direction control in the gas collection space by adjusting the negative pressure intensity and the airflow direction, seals the leveling liquid on the entrance side of the tempering machine and avoids the splashing of the leveling liquid caused by the chaotic reflection direction of the purge airflow or residual defects.

[0038] The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap