Buffering structure of windproof zipper

A technology of windproof cable and buffer structure, which is applied in the direction of load hanging components, safety devices, transportation and packaging, etc. It can solve the problems of cracking at the weld seam and large hidden dangers, so as to protect the weld seam and increase safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

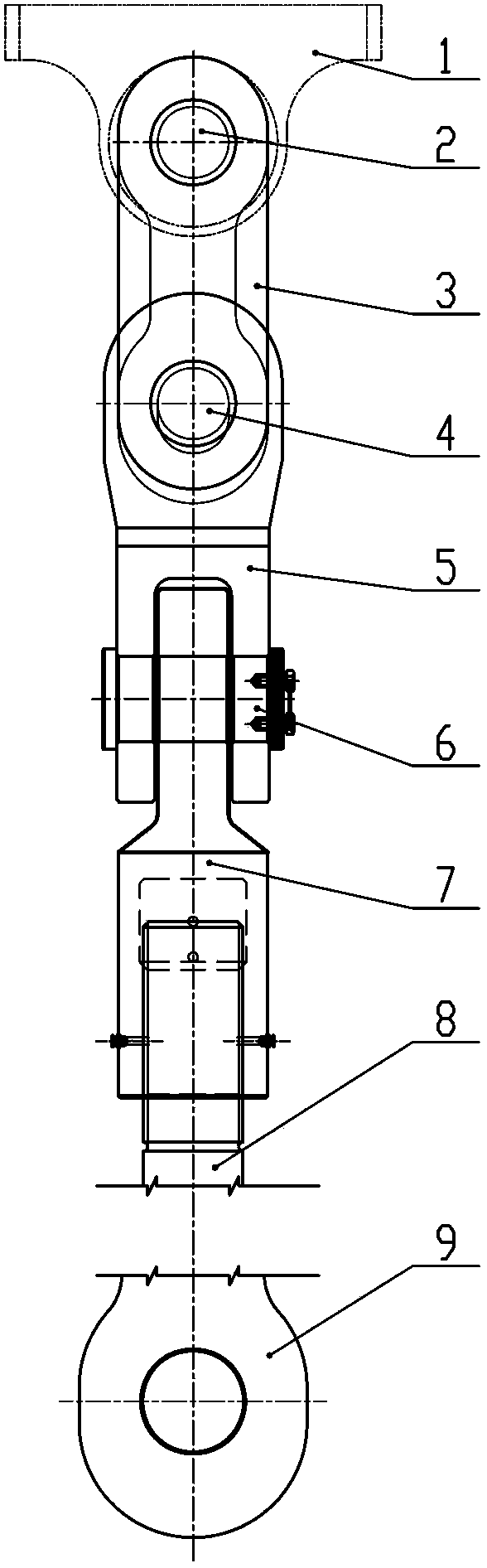

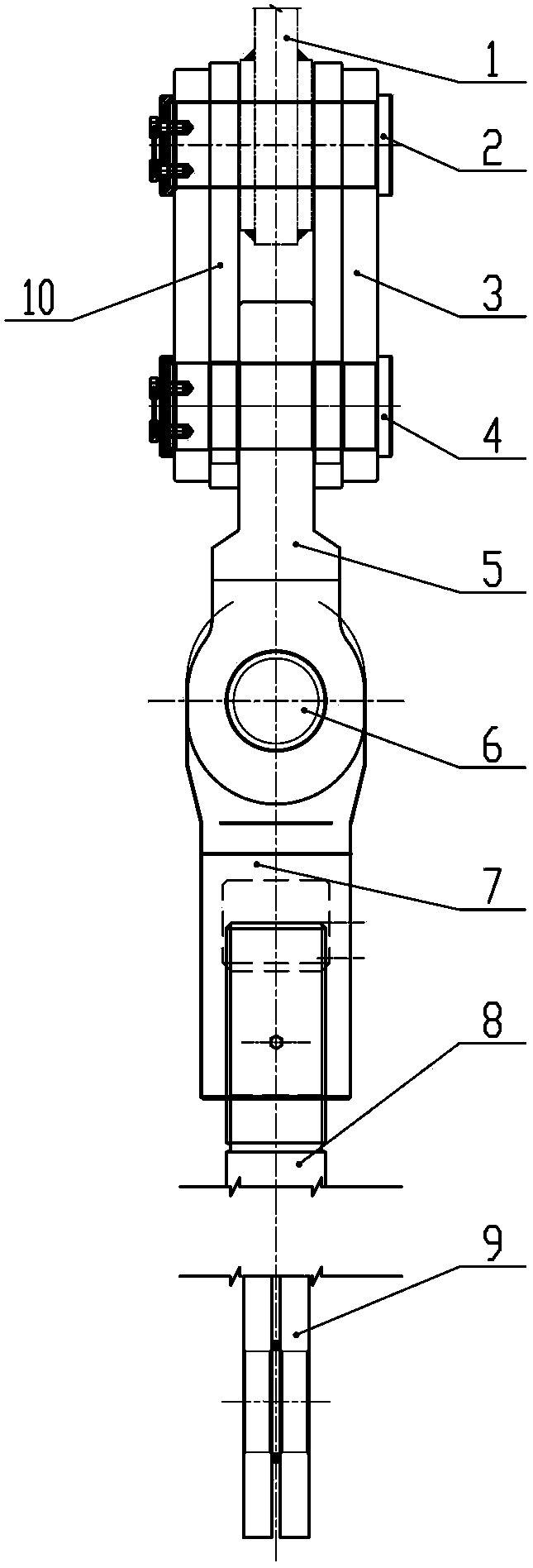

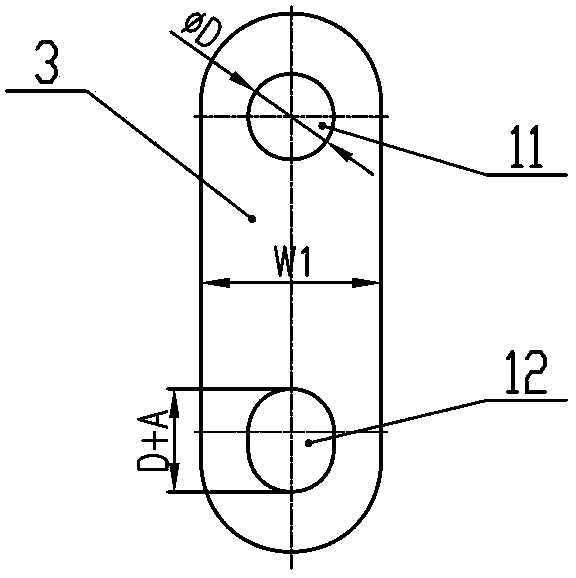

[0016] Figure 1 ~ Figure 4 Middle, including pull lug 1, pin shaft 2, main board 3, upper pin shaft 4, upper connector 5, middle pin shaft 6, middle connector 7, threaded connecting rod 8, lower connector 9, buffer plate 10, round hole 11. Waist hole 12, round hole 13, round hole 14, etc.

[0017] Such as figure 1 , figure 2 As shown, the windproof cable includes an upper connector 5, a middle connector 7, a threaded connecting rod 8 and a lower connector 9. The middle connector 7 is connected to the upper connector 5 through the middle pin shaft 6, and the middle connector 7 and the lower connector The heads 9 are respectively connected to the two ends of the threaded connecting rod 8 by threads with opposite directions, and the lower connecting head 9 is connected to the ground anchor of the port through the ear plate.

[0018] The present invention is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com